Silicone vs Plastic Cookware: Which is Better?

In an era of advocating health and environmental protection, more and more families pay more attention to “health, safety and durability” when purchasing kitchenware. Silicone and plastic cookware are common materials. Although both are light and easy to use, there are significant differences in temperature resistance, safety performance, environmental protection, service life and cost. This article compares silicone and plastic materials from multiple dimensions such as cooking experience, safety, environmental protection, cost, etc., to help you comprehensively judge “silicone kitchenware vs. plastic kitchenware, which is better”.

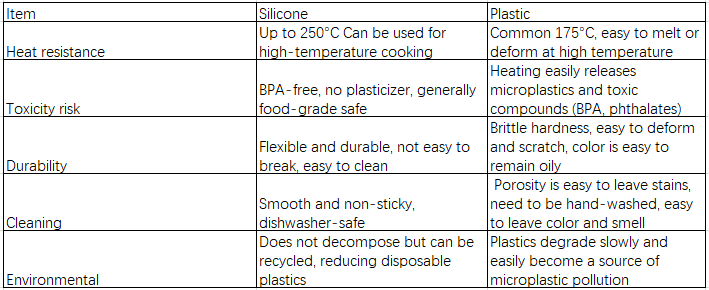

Silicone kitchenware has a heat resistance of up to 482°F (about 250°C), far exceeding plastic (about 175°C). Silicone has good heat resistance and chemical resistance, while plastic has the risk of releasing microplastics and additives. Long-term use feedback shows that “silicone kitchenware is more durable in the kitchen and is actively recommended to replace plastic kitchenware to avoid microplastic leakage”. Therefore, silicone kitchenware is more suitable for modern kitchens with higher requirements for safety and quality than plastic kitchenware.

What is silicone cookware?

Silicone cookware (also known as silicone kitchenware) is a cooking tool made of food-grade silicone, mainly used for cooking, baking, stirring and other operations in the kitchen. Its characteristics include high temperature resistance, strong chemical stability, easy cleaning, and compliance with FDA / LFGB safety standards.

Classification

Silicone kitchenware is mainly divided into two categories:

- Pure silicone kitchenware: Made entirely of silicone materials, such as silicone spatulas, spoons, etc.

- Encapsulated silicone kitchenware: Silicone encapsulates hardware or plastic materials, such as stainless-steel encapsulated kitchenware.

Safety

Food-grade silicone is non-toxic and odorless, with a temperature range of -40℃~230℃, in line with international safety standards (such as FDA, LFGB certification), and is not easy to release harmful substances.

Features

- High temperature resistance: Can withstand high temperatures of 230℃, suitable for microwave ovens, ovens and other scenarios.

- Anti-stickiness: The surface is smooth and not easy to stick to the pan, and it is easy to clean.

- Flexibility: The silicone material can be bent to fit different pot shapes to avoid scratching the pot.

Z.S.R is a professional custom silicone cookware products manufacturer, specializing in food-grade, heat-resistant cookware such as spatulas, baking mats, lids, molds, oven mitts, and more. Perfect for private labels, promotional brands, and bulk wholesalers with full OEM/ODM customization.

Custom Silicone Products | OEM/ODM Service

What is plastic cookware?

Plastic cookware (or kitchenware) is tableware or kitchen tools made of plastic as raw material, mainly used for food processing, cooking and holding food. Common materials include thermoplastic materials such as polypropylene (PP), polystyrene (PS), melamine resin (melamine tableware) and nylon (PA), with a melting point of about 175°C, an upper limit of about 350°F, and weak flexibility.

PP cookware

High temperature resistant (up to 120°C), does not contain bisphenol A, is often used for microwave heating or frozen food packaging, and is relatively safe.

PA cookware

Nylon kitchenware is a kitchen utensil made of polyamide (PA) material, which has the characteristics of high temperature resistance and lightness, and is commonly seen in tools such as spatulas, soup spoons, and funnels.

Material characteristics

Nylon material (also known as PA) is a thermoplastic resin with a repeating amide group in the main chain of the molecule. Common types include PA6 and PA66, which have the characteristics of high temperature resistance (up to 240°C) and good wear resistance.

Why do we need to distinguish plastic cookware and silicone cookware?

The distinction between silicone cookware and plastic cookware is mainly based on differences in material properties, safety, and usage scenarios.

Silicone cookware is suitable for high-temperature cooking (such as baking, frying), anti-fall design (such as silicone pot lids, anti-scalding gloves), and is commonly seen in kitchen tools and baby tableware.

Plastic cookware is mostly used in low-temperature scenarios (such as refrigerated containers, non-food grade tools), has limited heat resistance and is prone to aging.

Who cares the difference of the silicone cookware and plastic cookware?

When will you use the silicone cookware?

Please use silicone cookware when baking, microwaving, freezing, or high-temperature steaming.

When will you use the plastic cookware?

- For daily storage, portable tableware, and disposable items, plastics that meet safety standards can be selected;

- For picnics or outdoor activities, silicone portable bowls can be selected, but plastics can also be selected for lightness and economy.

Where do you use silicone cookware?

Baking trays, baking molds, kitchen gloves, storage bags need high temperature resistance, please choose the silicone cookware.

Where do you use plastic cookware?

Picnic plates, food containers, egg beaters, etc do not need high temperature resistance, you can choose plastic cookware to save the cost.

How to Produce the silicone cookware?

The production process of silicone cookware mainly includes key steps such as mold development, raw material processing, molding vulcanization, and post-processing: the production process is through liquid injection (LSR) or compression molding, which requires high-temperature molds and cooling.

Mold development

First, develop plastic molds and silicone molds according to the product design drawings. The plastic mold is used to make high-temperature resistant handles, and the silicone mold is used to mold the surface silicone part. The mold needs to be precisely designed and positioned to ensure that the plastic part and the silicone are molded in one piece.

Raw material processing

The raw materials need to be screened and cleaned, and the silicone base material, color glue, vulcanizer and other auxiliary materials are mixed according to the formula. After mixing evenly, the sheets are produced. The color matching process needs to strictly control the color difference to ensure the uniform appearance of the finished product.

Molding vulcanization

Put the plastic handle and the silicone sheet into the mold for high-temperature vulcanization. The temperature (usually 170-200℃) and pressure need to be precisely controlled to ensure that the materials are fully cross-linked. The encapsulation process needs to pay attention to the positioning and coordination of the plastic parts and the silicone to avoid deformation or edge bursting.

Post-processing

After vulcanization, the burrs need to be trimmed manually, and defective products need to be removed through full inspection. Some products need secondary vulcanization to remove residual low-molecular compounds and improve mechanical properties and safety. The final product uses moisture-proof packaging and ensures transportation protection.

Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(48 sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc.

Contact Z.S.R to kick off your silicone products brand here!

How to produce the plastic cookware?

The production of plastic kitchenware is mainly achieved through injection molding, blow molding, and extrusion molding processes, which are mainly divided into four core links: mold design, raw material selection, injection molding and post-processing:

Mold design and manufacturing

First, make the injection mold according to the product design drawings, and accurately design the parting surface, demolding system and runner balance. For example, the stepped parting surface is used to avoid flash, and the nitrogen spring ejection mechanism reduces the demolding defect rate. The selection of mold steel must take into account food-grade safety and durability. P2 pre-hardened steel or S136 stainless steel is commonly used, and mirror polishing is used for surface treatment.

Raw material selection

Select the type of plastic according to the product function:

High temperature resistant material: such as PP, PE, PA, Nylon, etc. are suitable for microwave lunch boxes and storage boxes

Special needs: Silicone materials need to be combined with plastic parts for high-temperature vulcanization molding, and high-temperature resistant plastics (such as food-grade PP) need to be selected

Injection molding process

Plasticization stage: Plastic particles are heated and melted by the screw and homogenized, and the temperature and screw speed need to be precisely controlled

Injection filling: Molten plastic is injected into the mold cavity at high pressure, and the injection speed and pressure parameters need to be optimized

Cooling and shaping: After molding, it is quickly solidified through a water- or air-cooling system to ensure dimensional accuracy

Mold release: Use ejector + gas-assisted mold release to avoid burrs

Post-processing process

Burr trimming: Hand-grind the mold line to ensure a smooth and burr-free appearance

Quality inspection: Check for defects such as burning, deformation or black spots

Surface treatment: Optional frosting, smooth and other hand-feel treatments to enhance the texture

How Much of the Silicone Cookware?

Silicone products: The unit price is higher, 2-5 times that of plastic; but due to the long service life, the long-term cost is lower.

How much of the plastic cookware?

Plastic products: Low-cost mass production, high recycling cost.

How to Choose the right cookware?

How to Control the Cookware Quality?

Silicone: strictly control the mold temperature, prevent demolding residue, and fully inspect for bubbles;

Plastic: strictly prevent BPA/PFAS addition, control production temperature to avoid odor, and enhance the clean and easy-to-wash properties.

How to Clean the Cookware?

More FAQs

Summary

Silicone and plastic have their own positioning: Silicone is suitable for high temperature, health, safety, and environmental protection requirements; plastic is suitable for low temperature, low cost, and short-term use frequency. When selecting materials, you should choose the appropriate material based on the use scenario, safety standards, and economic ability. If you have a silicone kitchenware project and need to make it, please contact us.

Z.S.R offer silicone Kitchen products technical support to the home-ware, house-ware, DTC and e-commerce brands, private label sellers, Kitchen gadget gift sets, Cooking schools & food companies and promotional industry. We work with brands, wholesale, retail chains, gifts store, and product development companies together. Offer the silicone kitchen utensils set, silicone kitchen accessories, silicone bowls, silicone baking mat, silicone baking mold, silicone brush, Silicone Cutting Board, silicone cooking utensils, silicone air fryer, silicone loofah, silicone utensils, silicone tools, silicone Clip-on Pan Strainer, Silicone Steamer, etc.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.