The best way to tell the difference of LFGB and FDA food silicone products?

First and First, LFGB silicone products and FDA silicone products is mainly reflected in the fact that they are both testing and certification projects for food contact materials, aiming to ensure the safety of the materials.

So the silicone products pass FDA 21 or LFGB , it is food grade safe!

Both LFGB and FDA test and certify food contact materials to ensure that the materials do not release harmful substances during use, thereby ensuring food safety.

Both LFGB and FDA apply to silicone products, especially those that come into direct or indirect contact with food, such as baby products, kitchenware, etc.

Both LFGB and FDA have strict requirements for the safety of silicone products. Silicone products that pass these tests are considered safe and can be used with confidence.

What is LFGB silicone products?

LFGB silicone products refer to silicone products used for food contact. These products must pass the LFGB test before they can enter the German market. LFGB is the abbreviation of the German Food and Daily Necessities Law (Lebensmittel-, Bedarfsgegenstände-und Futtermittelgesetzbuch), an important legal document in German food hygiene management, mainly used to ensure the safety of food contact materials.

Definition and standards of LFGB silicone products

The LFGB standard requires that substances in food contact materials and products, such as heavy metals, harmful additives, etc., cannot migrate into food to ensure food safety. Specific test contents include extractable ingredients, sensory inspection, odor and taste testing, lead and cadmium content, volatile organic compounds (VOM) and polycyclic aromatic hydrocarbons (PAHs) content, etc.

Silicone products that pass the LFGB test are considered to be products that do not contain chemical toxic substances and can be sold in the German market.

What is FDA silicone products?

FDA silicone products refer to those made of silicone materials that have been certified by the FDA. These materials strictly control the quality of raw materials during the production process to ensure that they do not contain harmful substances and pass the strict testing and certification of the FDA. FDA silicone products must meet the standards of the FDA, namely the provisions of Title 21 of the Federal Regulations, to ensure their safety for humans.

The main purpose of Food-grade silicone is used for the manufacturing of food-contact products. Food grade silicone is a type of silicone that is safe for use with foods. Silicone is used frequently in making molds to use for food that begins as liquids and solidify. It is non-toxic; does not stain food, dishes or cookware; is easily removed from cast objects; and is safe for use on various plastic objects.

Food grade silicone is non-toxic and odorless, environmentally friendly – contains no BPA, Latex, Lead, Phthalates and is biodegradable, long-term use, and other characteristics. Food-grade silicone is platinum cured with high elasticity, high transparency, and high tear strength. It meets the FDA and other environmental requirements. It is safe to contact food directly.

Food-grade silicone is a versatile and robust man-made synthetic polymer, made up primarily of non-toxic silica.

More About Food Grade Silicone

Known for its unique features, food-grade silicone is resistant to extreme temperatures, stresses and environments. Food-grade silicone is commonly used for a wide range of purposes within the food and beverage sector, replacing more traditional options such as rubber.

FDA compliance signifies that the material is safe for direct contact with food, making food-grade silicone an ideal tool to be used within the manufacturing, packing, packaging, transport or holding of food.

There are two testing standards for Silicone that can be sold that are considered food grade.

For silicone food-grade products, there are mainly two standards, one is LFGB food grade, another is FDA food grade. Silicone products that pass either one of these tests are safe for human use. LFGB is standard mainly for Europe, while FDA (Food and Drug Administration) is the base level standard in the USA and Australia. Most countries have their own FDA standard, but the USA FDA is the most internationally applied. In terms of pricing, products in LFGB standard will be more expensive than FDA standard, so FDA is more widely used. This is because LFGB method of testing is more comprehensive and strict.

In the US & Australia, the minimum standard for silicone products is ‘FDA’ testing (Food & Drug Administration standard).

Silicone products sold in Europe except for Germany & France must meet the European Food Contact Regulations – 1935/2004/EC.

Silicone products sold in Germany & France must meet ‘LFGB’ testing regulations which are the toughest of all standards – this type of silicone material must pass more intensive testing, is of better quality and is, therefore, more expensive. It is also known as ‘Platinum Silicone’.

“The LFBG (Lebensmittel-, Bedarfsgegenstände-und Futtermittelgesetzbuch, or “Foods, Consumer Goods and Feedstuffs Code”) is sometimes thought to be the European equivalent of the FDA. This is not quite correct. The LFGB is the German enactment of European law as operated by the Bundesinstitut für Risikobewertung (BfR). The BfR recommendations for food-contact materials are some of the more comprehensive in the EU”. Reference.

The mark “Knife and fork” is a symbol of food safety. For food contact material, if there is a “knife and fork” symbol, it means that the product has passed the inspection raised by a number of European countries including Germany.

LFGB: This is the German food contact material regulation for the EU market. LFGB tests include extractable ingredients, sensory inspection, odor and taste testing, lead and cadmium content, volatile organic matter (VOM) and polycyclic aromatic hydrocarbons (PAHs) content, etc.

LFGB’s testing methods are more comprehensive and strict, so silicone products that pass LFGB testing are generally considered safer.

FDA: This is the abbreviation of the US Food and Drug Administration, targeting the US market. FDA has clear regulations on silicone rubber products for food contact, including formulations and vulcanization conditions, etc.

FDA is more widely used, but silicone products that pass LFGB testing are more expensive.

FDA silicone products are widely used in food manufacturing and food contact products, such as food molds, baking utensils, tableware, seals, food packaging materials, etc. These products have the characteristics of anti-slip, wear resistance, and easy cleaning, which improves the hygiene quality and eating experience of food.

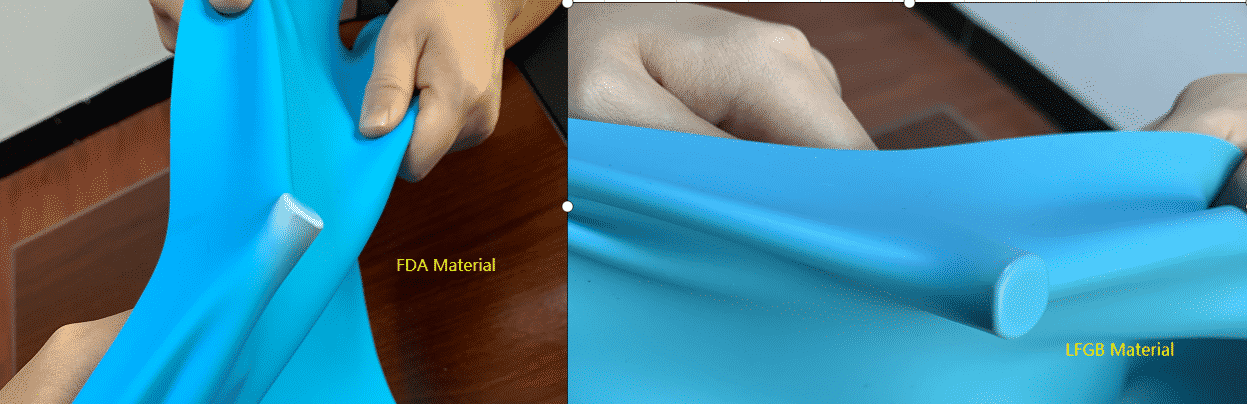

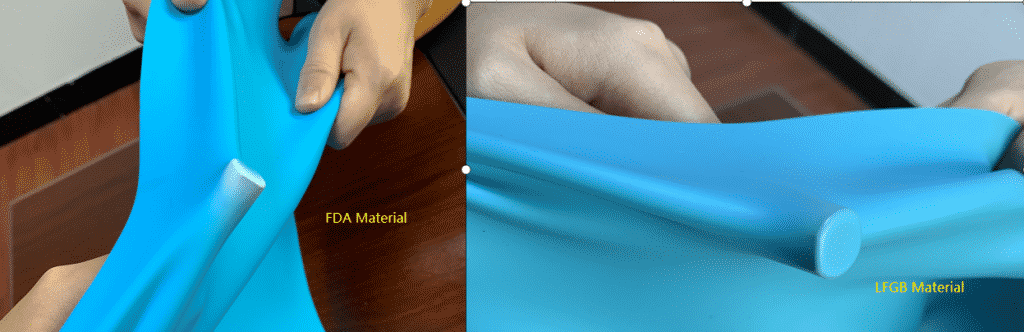

Here as a Manufacturer of molded Silicone products. The best and simplest way to tell the difference between LFGB and FDA food silicone products:

Pull harder or Twist:

Both hands pull hard on both sides or Twist. If there is white, it is FDA food Grade silicone products. If there is no white, it is LFGB food Silicone products

Contact Z.S.R if you have any molded silicone products that need to be customized.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.