Top 10 Custom silicone molding services Factory in China

With the innovation of new silicone products and the diversification of consumption, the demand for customized silicone products is growing rapidly. China boasts a vast array of high-capacity and cost-effective factories specializing in silicone molds, silicone compression molding, silicone injection molding, and silicone dripping molding. This article identifies the top 10 custom silicone mold and product manufacturers in China, providing a comprehensive analysis of their product capabilities to help global brands and OEM clients accurately select suppliers.

Factory ranking and areas of expertise

1. Z.S.R International Group (HONG KONG) CO., Limited

Z.S.R International Group (HONG KONG) CO., Limited is an customized silicone products enterprise integrating the design, development, production, package, printing. The founder has been deeply involved in the silicone products industry for 26 years and founded first silicone molding factory in 2007 in Donguan.

In the past 18 years, Z.S.R International Group (HONG KONG) CO., Limited has continued to improving. In order to provide customers with competitive silicone products, it has established five independent production factories: silicone compression molding factory, liquid silicone molding factory, dripping molding production factory, silicone leather cure fabric molding factory and mold manufacturing factory. The total production workshop area exceeds 30,000 square meters and currently has more than 300 employees. The factory has 6 fully automatic EMD spark machines, 10 advanced CNC machining centers, 48 compression molding machines, 16 dripping molding production lines, 12 liquid silicone injection molding machines, and printing, spraying, dust-free workshops (100,000 level) and other complete production and supply systems.

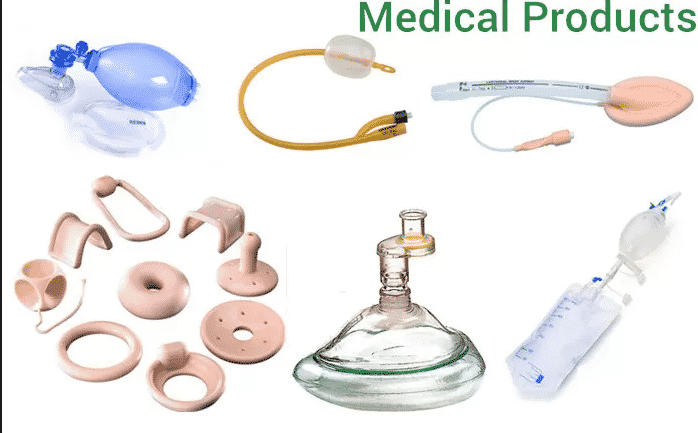

The silicone products what Z.S.R custom widely covering silicone daily necessities, baby products, gifts, electronic and device protective case, in consumer filed, also medical, commercial, industrial filed.

Company Advantages:

1. Direct from the Manufacturer: Z.S.R is the original manufacturer for molded silicone products. Customers can purchase the silicone products directly from the source, eliminating the need for middlemen and ensuring the best possible prices.

2. One-stop customized OEM/ODM solutions and diversified customization and branding capabilities

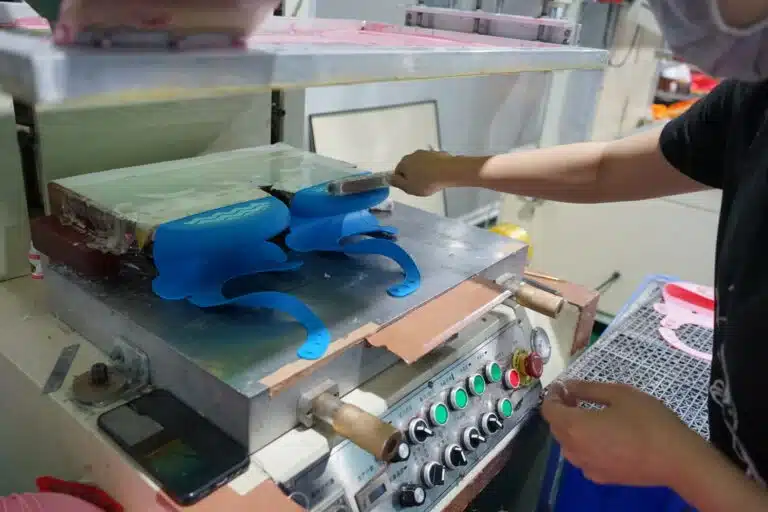

Since its establishment in 2007, Z.S.R has provided full-process services from design, proofing, mold manufacturing, molding, printing, assembly to quality inspection and packaging. Customers can complete the entire production chain from the same supplier. Supports a variety of logo processes: in-mold engraving, laser, silk screen, thermal transfer and epoxy; can customize color (Pantone), texture, packaging methods according to customer needs to achieve highly branded output.

Custom Silicone Products | OEM/ODM Service

3. Rich production capacity and advanced technical equipment

Owns:32 compression molding machines, 12 liquid silicone molding machines (LSR), 8 multi-color co-injection molding equipment;

CNC numerical control and EDM spark machines are used for mold manufacturing and debugging; and the daily production capacity reaches 20-550k pieces to ensure efficient delivery of large-volume orders.

4. Strict quality management and international qualification certification comprehensive quality assurance and after-sales service

The quality and social responsibility systems that have been obtained include:

ISO9001, ISO14001, SA8000, BSCI, SEDEX, BRC, FCCA, NBCU, Disney and other certifications;

The materials used comply with international food and safety standards such as FDA, LFGB, EN71, CE, ROHS, REACH, etc.

5. Strong R&D team and mold manufacturing capabilities

Equipped with 12 technical design engineers, who are good at product development, structural design and mold optimization; At the same time, they have mold surface treatment capabilities, such as polishing, laser engraving, coating, sandblasting, etc., to support highly customized needs

6. Stable and fast delivery and perfect after-sales system

With global logistics shipping channels (DHL/UPS/FedEx Sea and air transportation), and provide complete after-sales service; through strict production monitoring and quality inspection system, ensure that orders are delivered to customers on time and with quality standards

7. Free Samples: Z.S.R provides free samples for quality reference with the clients pay the shipping cost. so, customers can see and assess the products firsthand—seeing is believing.

2. 东莞市众盛硅胶制品有限公司

Jution silicone are a professional silicone baby products manufacturer in China. With rich experience in silicone baby products manufacturing, provide one-stop silicone technical support from material to mass production. Jution is the top choice of high-end silicone baby products for baby brands, wholesalers, retailers.

The in-house capabilities include: Product design and development Engineering silicone mold making, silicone molding: Compression molding, Liquid silicone rubber (LSR)molding, Co-injection dripping molding. Multicolored silicone products printing and painting assembling, package, quality assurance.

Jution Silicone & Rubber (Dongguan) Co., Ltd located at “world factory” base – Dongguan City, over 5000 square meters dust-free workshop and 200 skilled employees.

Company Advantages:

1: Rich industry experience and deep cultivation in the field of silicone

With more than 16 years of experience in silicone product manufacturing (established in 2007), covering tableware, baby products, kitchen supplies, home furnishings and gifts.

Cumulative exports to more than 30 countries, customer base includes Disney, Coca‑Cola, Hello

2: High standard food grade and safety compliance qualifications

All raw materials use 100% food grade silicone, in line with FDA, LFGB, REACH, RoHS, PAHs, phthalate-free and other certifications

The factory has passed SA8000, ISO9001, ISO14001, BSCI, NBCU and other international certifications, and has a complete quality management system

3: Complete OEM/ODM full-process service capabilities

Provide one-stop support: from design, mold manufacturing, LSR/SSR molding, multi-color co-injection, printing and spraying to assembly and quality inspection

Support low MOQ (about 500-1000 pieces) and fast proofing, suitable for brand owners and small and medium-sized batches to develop brand paths.

4: strong technical research and development and mold production support

Equipped with a professional engineering team and advanced mold equipment such as CNC and EDM, mastering self-developed molds and surface texture processes

Quickly quote according to customer drawings or 3D CAD files, and provide process optimization suggestions

5: high standard quality control and customer satisfaction

Implement 100% full inspection + random inspection product standards to ensure consistent and reliable export quality.

Fast response speed, 100% on-time delivery rate, customer feedback “professional, high quality”

6: diverse products, flexible customization

Wide product coverage: including baby products (tableware, chewing toys), kitchen utensils, pet products, gifts and watch accessories, etc.

Provide rich customization options: LOGO, pattern, color, material, packaging, to meet the diverse needs of brand/ODM customers

In short:

Jution brings together professional experience + food-grade safety + one-stop customization + high-quality delivery + customer reputation, and is an internationally competitive silicone product OEM/ODM leader.

3. 东莞市玖壹硅胶科技有限公司

Joey Silicone has provided customers with high-quality services for 3 years. The company mainly provides: new silicone material technology research and development; silicone rubber product manufacturing; rubber product sales; kitchenware, sanitary ware and daily sundries research and development; hardware product manufacturing; hardware product wholesale; mold manufacturing; mold sales; arts and crafts and ceremonial products manufacturing; arts and crafts and ceremonial products sales; high-quality synthetic rubber sales; synthetic material manufacturing; synthetic material sales; electronic product sales; import and export of goods.

4. 东莞市铭川滴胶礼品有限公司

Mingchuan Dijiao Gift Co., Ltd is a leading manufacturer of multi-colored baby products (baby teethers, feeding bottles, baby bibs, baby toys and pacifiers) and kitchenware (cookware, tableware, silicone molds and baking utensils) with over 2000 products, mainly distributed in Europe Japan, Korea, Australia USA/Canada and Brazil. Our factory is in China and sales department is in the United States.

Our factory in Dongguan covers an area of 2500square meters and has 83 employees. With over 23 years of experience in this field, we have developed our own R&D team to create over 300 new products and OEM every year.

5. 东莞市智盛礼品有限公司

Dongguan Wisdom-win Gift Co., Ltd. is a factory specializing in multi-colored silicone products and customized silicone gifts. It is committed to providing customers with professional multi colored silicone gift design, customization and production services.

Dongguan Wisdom-win Gift Co., Ltd was founded in 2013. Over the past 12 years, the company has continued to change to better provide customers with competitive silicone products. It has 15 drip molding production lines, mainly producing multi-color drip products, and is equipped with printing, spraying, and other complete production and supply systems. They are specializing in the development, design, production and processing of silicone epoxy accessories, silicone epoxy mobile phone cases, USB flash drive cases, key epoxy tags, epoxy placemats, silicone epoxy bracelets, epoxy necklaces, silicone epoxy trademarks, epoxy environmentally friendly trademarks, epoxy pendants, epoxy dolls and other gifts. The silicone raw materials, spray paint and printing materials we use all meet export standards. The products have passed environmental safety tests and meet various testing requirements such as ROHS/FDA/LFGB/UL. With its strong strength and excellent customer service, the company conducts full inspections on all products to ensure strong quality. We can develop and produce various types of silicone rubber products according to customer drawings, samples, and self-design. Our products have been distributed in more than 30 countries and regions around the world, with internationally renowned customers such as SONY, COCA-COLA, HELLO KITTY, AVON, etc. silicone products as the core, covering silicone daily necessities, baby products, gifts, medical, electronics, industry and other silicone product fields.

6. 东莞市瑞丰硅胶制品有限公司

Dongguan Ruifeng Silicone Products Co., Ltd. was established on April 27, 2011. It is located on Shipai Town, Dongguan City, Guangdong Province. It is a company specializing in the research and development, production and sales of silicone products.

The company mainly manufactures silicone products. Its main products include silicone kitchenware, daily necessities, mobile phone cases, etc. The products are exported to America, Europe and other places. The cooperative customers include well-known companies such as Disney and Walmart.

As of 2025, the company has 19 patented technologies and has passed the ISO9001 quality management system certification. The production facilities include a large mold workshop and 16 silicone hydraulic presses and 3 high-end precision liquid silicone machines. The number of employees in 2023 is 15.

7. 东莞市东坑浩盛硅胶制品厂

Dongguan Haosheng Silicone Products Factory

Dongguan Haosheng Silicone Products Factory was established in October 2011. It was jointly established by three people.While the factory is growing and developing, the shareholders have also developed separately.

Haosheng Silicone Products Factory is a wholly-owned private enterprise. Our factory now mainly produces silicone kitchenware and silicone accessories as well as electronic silicone accessories, such as silicone ice trays, silicone baking trays, silicone bracelets, silicone perfume covers, silicone luggage tags, earphone covers, earphone earplugs and Other beauty tools, makeup tool sets and other products. The factory have 39 employees.

8. 东莞市杰普达硅胶科技有限公司

Dongguan Jiepuda Silicone Technology Co., Ltd.

Dongguan Jiepuda Silicone Technology Co., Ltd. was established in 2017. It is an e-commerce direct sales enterprise specializing in the development of silicone rubber products, customer customization, and other production and manufacturing.

It currently has more than 60 senior technical personnel and outstanding employees, with an annual sales volume of more than 20 million yuan. It has more than 30 imported and domestic advanced production and testing equipment.

Main products: silicone products such as baby products, beauty and skin care, kitchen utensils, wearables, mobile phone accessories, etc.

The production base is located in Zhongkeng Village, Shipai Town, Dongguan City, Guangdong Province.

9. 东莞市博高硅胶制品有限公司

Dongguan Bogao Silicone Products Co.Ltd

Dongguan Bogao Silicone Products Co., Ltd. is located in Liaobu Town of Dongguan City.

It specializes in the production of silicone bracelets, silicone protective cases, silicone watches, various silicone buttons, silicone wallets, silicone backpacks, handbags, and silicone toys. It is a manufacturer that provides various types of advertising products, exquisite gifts, promotional gifts, etc. for major enterprises and institutions.

At present, the company has more than 20 imported large-scale equipment of various types, more than 30 skilled designers and technicians, and a daily output of more than 100,000 PCS.

10. 东莞伟兴电子科技有限公司

Dongguan Weixing Electronic Technology Co., Ltd

Dongguan Weixing Electronic Technology Co., Ltd. is located in Chashan Town, Dongguan City, Guangdong Province.

Our company specializes in the production of electronic components, silicone rubber and various accessories, hydraulic products, Household silicone products, various silicone rubber parts, professional hardware rubber coating, plastic parts rubber coating, comb leather, needle threading rubber, blood pressure meter special-shaped connection silicone tube, high-temperature silicone products, rubber rings, dust plugs, waterproof sealing rings, wire protection sleeves, sealing rings, single-sided adhesive silicone rubber foot pads, overload protector high transparent silicone more than 20 years.

What is Custom Silicone Molding Service?

Custom silicone molding services involve designing molds and producing silicone products based on customer needs. This service encompasses steps such as needs analysis, material selection, mold development, and production processing, ultimately delivering silicone products that meet specific performance and appearance requirements.

Core Steps

Requirements Analysis:

Communicate with the customer regarding parameters such as size, shape, and hardness, clarify the application scenario (such as medical, food, or electronics), assess technical feasibility, and optimize the design.

Mold Fabrication:

Develop the mold based on the design drawings, taking into account factors such as demolding difficulty and material shrinkage to ensure production accuracy.

Production and Processing:

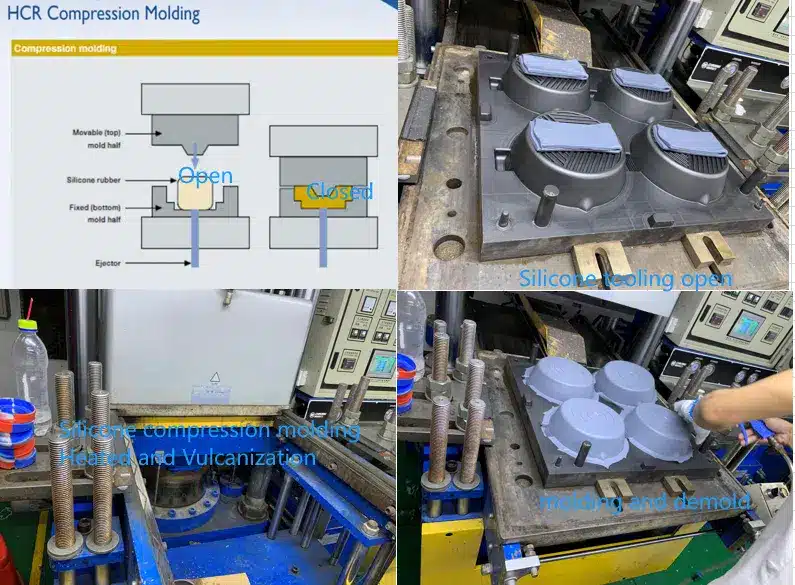

The finished product is formed using compression molding, injection molding, or extrusion, followed by vulcanization and other processes.

Quality Control:

Dimensional tolerances and physical properties (such as temperature resistance and tensile strength) are tested to ensure compliance with standards.

These factories offer services such as liquid silicone injection molding (LSR), hot press molding, overmolding, epoxy molding, CNC silicone mold processing, and food/medical-grade certification. They provide a comprehensive, one-stop customized service, from product design and mold development, raw material procurement, production, to finished product testing, packaging, and logistics.

Why is China’s silicone custom molding service the first choice?

Fast Delivery and Flexible Customization: The mold-making cycle for complex structural parts can be shortened from 50 days to 30 days, reducing the cost of small-batch figure customization by 60%. Rapid design modifications are supported, and after adjustments to the master mold, a remold can be created without re-molding. Delivery times are as short as 7 days, and expedited orders are available.

High-Precision Process Guarantee: Silicone mold remolds achieve a precision of ±0.05mm, resulting in a smooth and seamless surface. Liquid silicone rubber (LSR) molding technology rivals German craftsmanship, with high injection precision (±0.01mm) and high production efficiency.

Large-Scale Industrial Advantage: China accounts for 70% of the global silicone product production capacity, forming three major industrial clusters: Dongguan (electronics-grade), Taizhou (medical-grade), and Qingdao (industrial-grade). Exports are expected to exceed US$12 billion in 2023, a 23% year-on-year increase, providing close proximity to overseas market supply chains.

Reliable Product Quality: Food-grade and medical-grade materials are available. Food-grade silicone boasts a purity of 99.99%, and is certified by over 50 global certifications, including FDA, LFGB, and REACH, meeting international safety standards.

Cost-effectiveness and localized service: Compared to European and American manufacturers, Chinese service providers offer 40%-60% lower costs for customizing complex structural parts. They support surface treatment (painting/silk screen printing/laser engraving) to enhance product quality and accommodate OEM/ODM customization, logos, and packaging.

Our custom silicone products from Z.S.R offer high cost-effectiveness, high production efficiency, high product precision, and guaranteed quality.

What challenges do custom silicone service providers in China face?

- Risk of IP infringement requires signing an NDA;

- Factory-induced mold quality fluctuations require on-site or video audits;

- Follow-up maintenance and technical support require an assessment of capabilities.

Who is most interested in custom silicone service providers in China?

Branded manufacturers of kitchenware, baby products, and kitchen tools need to choose the right molding service provider.

The medical device, automotive parts, and electronics industries need factories that can source silicone parts and products.

Overseas small and medium-sized enterprises seek custom brands with low MOQs.

When do you need custom silicone molding services?

First, when your silicone product needs to transition from prototype to mass production.

Second, if you require small batches of multiple versions, Chinese custom silicone molding service providers can provide this service.

Third, if you’re looking for cost-effectiveness and process compatibility, Chinese custom silicone molding service providers can spread the mold costs across the silicone product itself.

Which industries require silicone molding services?

1. Factories producing parts for various industries, including small appliances, automotive, consumer electronics, tool accessories, and medical device silicone parts.

2. Factories producing food safety products (such as silicone molds and rice cooker gaskets).

3. Brand owners of silicone kitchen products, silicone furniture, silicone maternity and baby products, silicone health care products, and silicone beauty products.

In short, any company or individual requiring custom silicone products may require silicone molding services.

How to Choose a Silicone Molding Service Factory?

When selecting a custom silicone molding service factory, focus on production capacity, technical expertise, quality certifications, and service systems. Specific key points are as follows:

Prefer manufacturers with ISO9001/TS16949/FDA certifications. Choose manufacturers with ISO9001 quality management system certification, FDA food-grade certification, and RoHS heavy metal testing to ensure product safety. For medical applications, additional verification is required, including ISO13485 medical device certification and biocompatibility reports.

Focus on the technical team’s expertise and craftsmanship, including molding technologies like liquid silicone injection molding and two-shot molding, and whether they offer customized solutions from design to production. It’s recommended to choose a manufacturer with a modular mold library. Discuss with the factory about their sample manufacturing capabilities and mold lifespan requirements; this can shorten the prototyping cycle for new products. Inquire about their availability of medical-grade materials.

Choose Z.S.R for the most professional, customized silicone product solutions.

Conduct a video or on-site audit of the factory site and equipment. When comparing quotes, consider product accuracy, delivery stability, and service levels to avoid falling for low-price offers. We recommend an on-site inspection of the workshop environment, focusing on the coverage of automated equipment and quality control processes. We also recommend reviewing after-sales service response speed (response within 24 hours and solution provision) and technical support (including confirmation of a three-year or longer warranty on non-standard products).

How much does custom silicone products cost?

The cost of custom silicone products is primarily determined by factors such as mold development, raw materials, process complexity, and production volume, as follows:

Mold Development Cost

Basic molds: Simple structures (such as silicone wristbands) cost approximately 5,000-20,000 yuan, while complex structures (such as multi-cavity molds) can cost up to 50,000-150,000 yuan.

Precision molds: Medical-grade molds require a mirror polish (Ra ≤ 0.2μm), and surface treatment fees increase by 30%-50%.

Raw Material Cost

Ordinary industrial silicone: 25-80 yuan/kg, suitable for daily necessities such as phone cases.

Food-grade silicone: 40-200 yuan/kg. Medical-grade silicone requires ISO 10993 biocompatibility certification and can cost up to 120-200 yuan/kg.

Liquid silicone rubber (LSR): 80-600 yuan/kg. Imported medical-grade raw materials can cost up to 400-600 yuan/kg, while domestic alternatives are 30%-40% cheaper.

Process Complexity

Molding Process: Compression molding costs approximately 0.5-2 yuan per piece, LSR precision injection molding costs 3-8 yuan per piece, and two-color layered printing adds 1.2 yuan per piece.

Post-Processing: Spray-on tactile coating adds 0.3 yuan per piece, and laser logo engraving adds 0.5 yuan per piece.

Impact of Production Quantity

Effect of Scale: The unit price for an order of 1,000 pieces is approximately 8 yuan, reducing to 2.5 yuan for an order of 10,000 pieces.

Mold Sharing: The mold sharing cost for an order of 10,000 pieces is approximately 8 yuan per piece, reducing to 0.8 yuan per piece for an order of 100,000 pieces.

Certification and Compliance

Medical-grade products require FDA and CE certification, and testing fees can reach hundreds of thousands of yuan.Food contact products require comprehensive migration testing. Some manufacturers only pass SGS heavy metal testing, which may lead to compliance risks.

How to choose between different silicone molding solutions?

Choosing a silicone molding solution requires a comprehensive assessment based on product requirements, production scale, and process characteristics. The following are the main process types and applicable scenarios:

- Compression Molding:

- Compression molding is one of the most commonly used production processes for silicone products. Silicone raw materials are placed in a mold and cured under high temperature and pressure.

- This process is suitable for large-scale production, offering low cost and high efficiency, and is suitable for general products such as seals and gaskets.

- Injection Molding:

- Injection molding involves injecting liquid silicone rubber (LSR) into a mold using an injection molding machine and curing it at high temperature.

- This process is suitable for silicone products with complex shapes (such as special-shaped parts) and offers high production efficiency, but the equipment cost is relatively high.

- Extrusion Molding:

- Extrusion molding involves continuously extruding silicone material through an extruder to form tubular, strip, or profiled products.

- This process is suitable for tubular and strip products (such as silicone tubing) and offers high continuous production efficiency.

- Calendering:

- Calendering uses a calender to press silicone material into sheets or films. Used for the production of thin sheets or films, suitable for thin products such as silicone sheets and films.

- Overmolding:

- Wrapping silicone around metal/plastic substrates is suitable for composite structures such as silicone-coated hardware and plastic-coated composites.

- Coating:

- Coating involves applying silicone material to the surface of a substrate to form a thin film or coating.

- Dip Molding:

- Dip Molding involves immersing a mold in liquid silicone, allowing the silicone to adhere to the mold surface and then solidify.

- 3D Printing:

- 3D printing is an emerging silicone molding process that creates complex three-dimensional structures by depositing liquid silicone material layer by layer.

- Transfer Molding (Die Casting):

- Transfer molding involves injecting silicone material into a closed mold under pressure and then solidifying it.

- Foaming:

- Foaming involves adding a foaming agent to the silicone, causing it to form a porous structure during the curing process.

- Vacuum Forming:

- Vacuum forming involves applying silicone material to the mold surface through vacuum suction and then solidifying it.

How to control the quality of custom silicone products?

Quality control for custom silicone products requires multiple aspects, including raw materials, process parameters, and environmental control. The following are key control points:

Raw Material Quality Control

upplier Audit: Select silicone raw material suppliers that are ISO/FDA-certified to ensure that the raw materials meet medical/food-grade standards. Before entering the factory, test indicators such as volatile matter (≤0.5%) and hardness deviation (±2 Shore A).

Storage Management: Warehouses must be dry and dark, and a first-in-first-out (FIFO) principle must be implemented to prevent moisture and prolonged storage, which can lead to performance degradation.

Formulation and Process Control

Formula Optimization: Add antioxidants (to slow oxidation) and light stabilizers (to prevent UV aging) based on the application scenario, and adjust the crosslink density to balance mechanical strength and moisture and heat resistance.

Molding Process:

Injection molding requires an injection rate of 15-25 g/s to avoid turbulent flow and bubble formation.

Compression molding requires venting slots (0.5-1 per square centimeter) and a temperature of 160-210°C.

Vulcanization Parameters: A PLC system monitors temperature (±2°C), pressure (8-15 MPa), and time (t90 + 10%) in real time. Medical products require a step-by-step vulcanization process.

Environmental and Equipment Management

Cleanliness Control: Medical-grade production areas require ISO Class 7 cleanliness, while electronic-grade production areas require electrostatic protection.

Equipment Maintenance: Regularly calibrate molds and equipment, and use automated injection molding equipment to minimize human error.

Quality Inspection and Maintenance

Online Monitoring: Use infrared thermometers, calipers, and other equipment to monitor production parameters in real time.

Finished Product Inspection: Test dimensional accuracy, bond strength, and appearance quality, and establish a quality traceability system.

Regular Maintenance: Inspect products for signs of aging, such as cracks and discoloration, and replace deteriorating parts promptly.

How to clean custom silicone products?

The cleaning method for silicone products depends on the type of stain and the intended use. The following are specific steps and precautions:

Daily Basic Cleaning (Light Stains):Warm Water + Neutral Detergent

Dilute neutral detergent in warm water at 30°C-40°C. Soak the silicone product for 10 minutes. Gently wipe the surface with a soft cloth or sponge. Rinse thoroughly with clean water and air dry. Suitable for common stains such as dust and oil.

Alcohol Wipe

Wipe the surface with a 70%-75% alcohol pad or soft cloth to quickly remove fingerprints, oil stains, and disinfect. Suitable for phone cases, electronic product covers, etc.

Deep Cleaning (Stubborn Stains):

- White Vinegar + Baking Soda

- Grease Stains/Pigmentation: Mix 1:1 white vinegar and water, soak for 15-20 minutes, scrub gently with a soft brush, and rinse.

- Yellowing/Mold Stains: Apply a baking soda paste to the stain, let it sit for 15 minutes, then scrub. Alternatively, soak the stain in a 1:3 ratio of white vinegar and warm water for 30 minutes.

- Toothpaste/Fluoropropyl Alcohol

- Apply toothpaste and gently scrub with a soft brush to remove yellowing caused by oxidation. Apply a drop of medicated oil to the stain, let it sit, then scrub. Suitable for glue marks, ink, etc.

Special Silicone Product Treatment

Kitchenware (baking molds, etc.)

Wash immediately with dishwashing liquid after use and disinfect regularly with a baking soda solution or white vinegar.

Dishwasher-safe (check for the heat-resistant mark).

Electronic product protective cases

Avoid soaking.

Use an alcohol pad to partially clean gaps to prevent liquid from seeping into the device.

Baby products/medical supplies

Boil in boiling water for 5-10 minutes (heat-resistant models), or disinfect with 70% alcohol.

Contraindications

- Avoid strong corrosive agents: Bleach and strong acid/alkaline cleaners can damage the silicone structure, causing cracking and aging.

- Avoid physical damage: Avoid using steel wool or hard-bristled brushes to prevent scratches.

- Drying: Dry in a well-ventilated area away from direct sunlight (which can cause deformation and discoloration).

- Do not soak for extended periods: This may cause the material to swell.

Maintenance Tips:

More FAQs

Summary

In summary, China has a rich resource for custom silicone molds, from rapid prototyping to mass production, to meet diverse budgets and performance requirements. By carefully selecting manufacturers with proven certifications, technical capabilities, guaranteed delivery schedules, and a strong after-sales commitment, such as Top 10 factories, we can ensure rapid product rollout and quality and safety. Brands should ensure transparent on-site and online factory inspections, sign IP agreements, conduct phased inspections, and implement follow-up repair and replacement mechanisms to build a foundation for long-term partnerships.

For more in-depth customization, manufacturer connections, or initial procurement support, please feel free to contact Z.S.R.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.