Poron VS Silicone

For elastomer applications, Poron and silicone rubber have their own advantages. Poron is famous for its excellent cushioning and compression resistance; silicone rubber is known for its high and low temperature resistance, chemical inertness, and safe skin contact. Engineers, purchasers, and brands often struggle: Which elastic material is more suitable for the current product? This article will compare from multiple dimensions such as performance, applicable scenarios, cost, and user experience to provide you with a reference for material selection decisions.

What is the Poron?

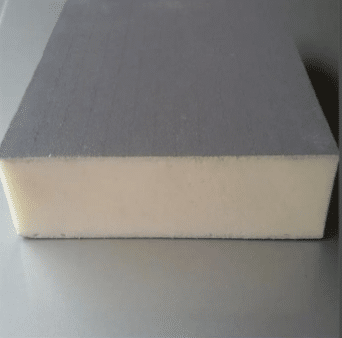

Poron is a high-performance bubble material with excellent cushioning, shock absorption and support performance. It performs well in shock absorption, sealing, heat insulation and other scenarios. It is made of special polyurethane material and is widely used in footwear, electronic products, sports equipment, medical equipment and other fields due to its unique structure and performance. Its stable performance and reliable quality make it an important part of many products, providing users with a comfortable, safe and reliable use experience. I believe that with the continuous development of science and technology, Poron material will show its excellent performance and potential in more fields.

PORON brand polyurethane foam material has high density, fine and uniform cell structure, and excellent resistance to compression deformation.

What is Silicone?

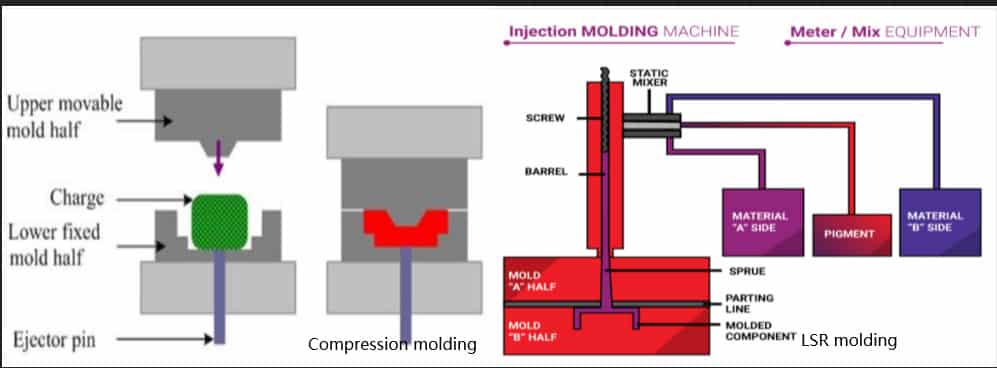

Organic silicone is a kind of organic silicon compound, which refers to a compound containing Si-C bonds and at least one organic group directly connected to the silicon atom. It is customary to also regard compounds in which organic groups are connected to silicon atoms through oxygen, sulfur, nitrogen, etc. as organic silicon compounds. Among them, elastomers based on the skeleton composition of silicon-oxygen bonds (-Si-O-Si-) are the most numerous, most deeply studied, and most widely used type of organic silicon compounds, accounting for more than 90% of the total usage. Including solid, liquid foam, sponge and other forms, it is resistant to extreme temperatures, non-toxic and inert, and is widely used in building sealing, medical maternal and child care, kitchen utensils and other scenarios.

Why Poron VS Silicone?

Poron and silicone are two materials commonly used in shock absorption, sealing or cushioning scenarios. The comparison can help users choose a more suitable material based on specific needs (such as shock absorption priority, feel preference or cost).

Who care the difference of Poron VS Silicone?

Electronic/mechanical manufacturers designer and engineer, when they need to select materials for shock absorption, sealing, and casing buffering, choose Poron. It is mostly used in electronic equipment (such as keyboard sandwich cotton), shoe materials, sports goods and other fields that require high cushioning and sealing. Its mesh hollow structure can absorb vibration. It achieves better sound insulation by absorbing air vibration. Poron is softer and more elastic, and Poron has stronger compression resistance. Environmentally friendly, high-density, chemical corrosion resistance, suitable for precision equipment.

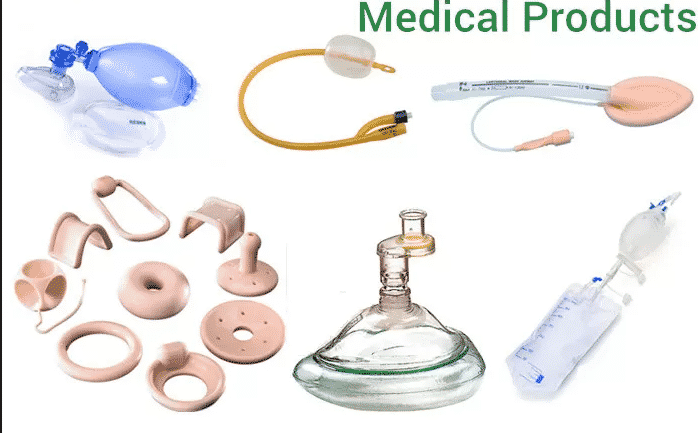

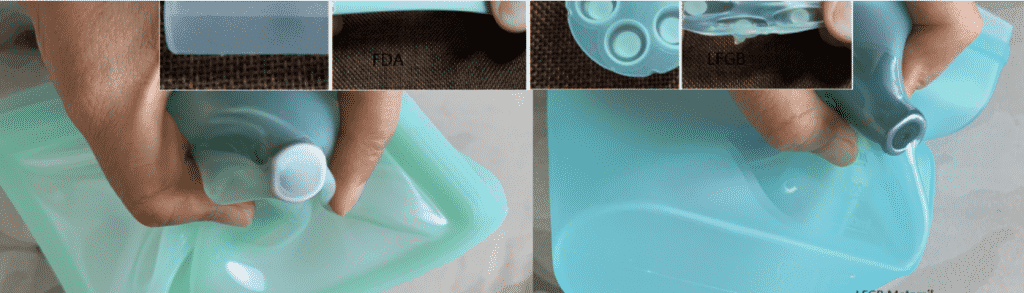

Medical & maternal and child brand owners, product developments manager pay attention to high-temperature disinfection and material safety. Silicone materials are preferred. Silicone is non-toxic, odorless, and will not react with human tissue. Its porous structure has good air permeability and is suitable for environments with long-term contact with skin or body fluids. Medical silicone has passed international certifications such as FDA and EU LFGB, and meets medical equipment safety standards. Food-grade silicone is also suitable for maternal and child products, such as pacifiers, tableware, etc., and does not release harmful substances. In the medical field, silicone is used for catheters, prostheses, artificial organs, etc. It has high biocompatibility and low rejection after implantation in the human body. Maternal and infant products such as silicone pacifiers and sealing rings take advantage of their anti-aging and easy-to-clean properties.

The designer and engineer from manufacturers of kitchenware and engineering parts need high-temperature resistant, oil-resistant, and highly sealed materials. Silicone is the first choice. Silicone materials are resistant to high temperatures (-60°C to 270°C) and have stable chemical properties.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Custom Silicone Products | OEM/ODM Service

When and Where for the Poron VS Silicone?

Keyboard pads, consumer electronics assembly, insoles, sports protective gear, etc. are the first choice for products that have high requirements for energy absorption and cushioning.

For products such as kitchenware, electronic device seals, medical consumables, automotive parts, and outdoor sealing strips, which need to withstand extreme temperatures, frequent disinfection or outdoor use, and require IP-level sealing, silicone is more suitable.

How to choose Poron VS Silicone?

The choice of Poron or silicone depends on the specific usage and needs:

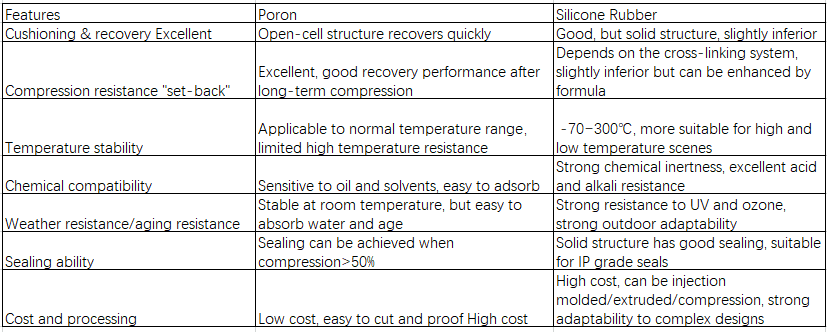

Material property comparison

- Poron

- Excellent shock absorption performance, can effectively absorb impact force, suitable for scenarios that require buffering (such as keyboard silencing, sports protection) . Structural characteristics are mesh hollow design, softer touch and can isolate air vibration conduction

- Silicone

- Outstanding anti-slip performance, soft touch and skin-friendly, suitable for anti-slip needs such as mobile phone cases , disadvantages easy to get dusty and need frequent cleaning, long-term use may turn yellow

Applicable recommendations

Poron is preferred for keyboard sandwich cotton. As its mesh structure can better isolate cavity sound and has a softer touch

Anti-slip needs (such as mobile phone cases): Silicone is better, the anti-slip effect is significant but attention should be paid to cleaning and maintenance

High temperature environment: Silicone has better high temperature resistance than Poron (silicone can withstand temperatures up to 350°C in a short term)

Z.S.R factory consists of a strong engineering design team 12 experts with more than 20 years’ experience. We offer personalized services and supports for projects through all steps of products development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly.

How much of Poron VS Silicone?

The price difference between Poron and silicone is mainly reflected in the material type and application field:

- Industrial field: The price of Poron foam is about 0.6-2 times that of ordinary silicone.

- Medical field: The price of silicone rhinoplasty is only 50%-75% of that of expanded material.

How to clean Poron VS Silicone?

Poron product cleaning :

Uncured treatment Rinse with clean water (large water volume and strong impact) or use special cleaning agent to scrub.

Cured treatment Carefully scrape off the surface curing layer with a spatula to avoid damaging the material. If necessary, use a special cleaning agent to dissolve it.

Silicone product cleaning:

General stains Soak in warm water (40-50℃) and wipe with a soft cloth, using neutral detergent.

Stubborn stains Wipe with alcohol or white vinegar (be careful to avoid direct contact with the skin), or use a professional cleaning agent.

Special materials Silicone that requires high temperature disinfection (such as medical grade) can be wiped with 70%-75% alcohol to avoid prolonged contact.

More FAQs

1. Can Poron be used for high-temperature disinfection?

It is not recommended. Poron is not resistant to high temperatures and is easy to absorb water.

2.Why is silicone more expensive than Poron?

It involves raw materials, production process complexity, certification costs and molding precision requirements.

3.Can Poron be covered on the surface of silicone?

It can be composite molded, for example, Poron is used as a buffer in a keyboard pad and silicone is used as a surface contact layer.

4.Service life comparison?

Poron has a service life of tens of thousands of times under compression; silicone has an aging resistance of decades.

5.Which is more environmentally friendly?

Poron has a certain degree of recyclability; silicone is usually not recyclable, but has a longer service life.

Summary

Correct material selection is based on performance matching, usage scenarios and cost considerations, which can significantly improve product value and user satisfaction.

Poron: low cost, strong cushioning, used in keyboards, pads, protective gear, etc.;

Silicone: high performance, extreme temperature resistance, suitable for high-end kitchenware, medical, injection molded parts;

The two can often be combined to achieve cost control + performance improvement;

If you need to obtain material performance testing, sample evaluation, injection molding/cutting service docking, silicone product material customization, Z.S.R company provides one-stop silicone material and silicone product technology and market support, welcome to consult!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.