Silicone Coaster VS Silicone Trivet, Which is better for you

In modern homes, offices and kitchens, silicone coasters and Silicone Trivets have become basic and frequently used kitchen and living accessories. Although they are made of the same material and are equally common, they have slightly different uses and different functions: coasters are anti-condensation and anti-slip; Silicone Trivets are responsible for high temperature protection. The right choice will help improve the desktop experience, enhance brand differentiation, and optimize sales conversion. This article analyzes the differences between the two and provides selection suggestions from a practical perspective. Help brands accurately identify user needs and improve products conversion rates.

Whether it is a silicone coaster or silicone Trivets, Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(48 sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone coasters and Silicone Trivets for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc.

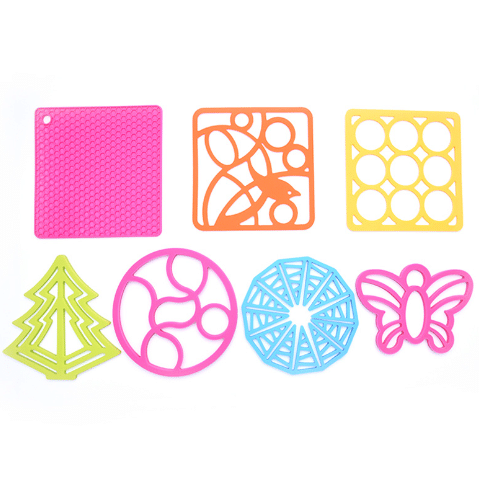

What are silicone coasters?

Silicone coasters are coasters made of food-grade silicone material. Silicone coasters are generally used in household items, heat-insulating, non-slip, and creatively decorated. They are made of food-grade silicone material and can be matched with various cups; the super heat-insulating function can effectively protect the desktop from being scalded, and the exquisite appearance can not only embellish the colorful life, but also has the effect of heat insulation and heat preservation; it is formed by high-temperature vulcanization of hydraulic press, high-temperature resistant, environmentally friendly and non-toxic, and is the most advantageous product in today’s society that conforms to the concept of environmental protection; silicone coasters are fashionable and generous, and can be flipped and changed into different shapes at will, which can be expanded for use, and the range is suitable for various cup diameters. You can safely place it on the table when enjoying hot drinks. The heat-resistant temperature is -40 degrees ~ 220 degrees. The material is environmentally friendly and non-toxic, which can protect the desktop from being scalded. At the same time, personalized design is achieved through multi-color one-piece molding process.

- Main features Material safety: Food-grade silicone is non-toxic and tasteless, insoluble in water or solvents, and meets environmental protection standards.

- Insulation performance: It can effectively isolate heat transfer and avoid burns on the desktop. It has a wide temperature range (-40℃ to 220℃).

- Anti-slip design: The friction is enhanced through special technology to prevent glass and porcelain cups from slipping.

- Durability: The service life is up to 7-8 years. It can be directly washed and cleaned and used repeatedly.

- Application scenarios:The thickness is about 2-4mm and the diameter is 8-12cm.It is mainly used in homes, restaurants, cafes and other places. It is both practical and decorative, and can be customized with patterns or shapes.

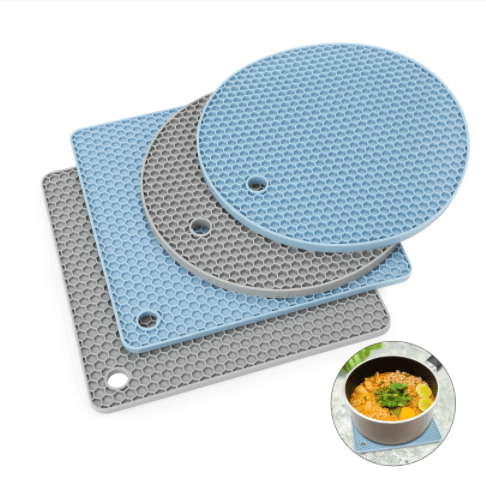

What are Silicone Trivets?

Silicone Trivets is a kind of insulation and protective product made of 100% silicone material. It has excellent insulation performance and high temperature resistance and is widely used in home, kitchen and industrial fields. Silicone Trivets is made of high temperature resistant and environmentally friendly silicone material, designed into concave, convex, hollow and other shapes, which can fully isolate the burns of high temperature kitchen utensils on the countertop. It can also be used as a cooking tool. The high temperature resistant silicone material can withstand the temperature of high temperature cooking and does not produce harmful substances. The silicone material is soft and can be twisted and stretched arbitrarily without deformation. Any size can be customized according to customer requirements.

Main use

Thickness 5-8mm, size generally 15-25cm, often used to place pots and hot plates to protect the desktop from high temperature or damage.

Suitable for heat insulation protection of high-temperature items such as pots, cups and plates, and electrical appliances (such as microwave ovens and ovens).

It can also be used for heat insulation of industrial equipment.

Why you need know the difference of Silicone Coasters VS Silicone Trivets?

The silicone Trivets can not only fix the camera, but also prevent pots and pans from sliding and scalding the desktop. In addition, the silicone Trivets can also be used for various home appliances, such as speakers, TVs, etc. Its buffering performance can play a role in shock absorption, making your home environment quieter and more comfortable.

Know the difference is easy for you to choose the right products for your application.

Who care the difference of Silicone Coasters VS Silicone Trivets?

Z.S.R work with brands, wholesalers, retail chains, gift stores, restaurants, coffee shops, hotels, E-commerce operators/sellers and product development companies offer their logo branded silicone mats to reflect their brand identity and enhance their brand recognition. Produce and supply variety custom silicone coaster and silicone trivets.

When will you use Silicone Coasters VS Silicone Trivets?

Daily drinking: Use coasters when placing teacups and coffee cups. Silicone coasters are not just a tool for protecting the desktop, they also have multiple functions. A silicone coaster with a diameter of 10 cm can accommodate most types of cups or pots, effectively improving the neatness of the desktop. This size is really practical, whether I use it to place a mug or a thermos cup, it is just right. Silicone coasters can also be used as heat insulation pads, which can withstand different temperatures and protect the desktop from being burned or dirty.

- Mealtime: Use heat-insulating Trivets when cooking, serving hot dishes, and placing pots.

- Family gatherings/parties: The combination of the two colors enhances the appearance.

- Holiday decorations: Use colorful coasters to match holiday themes.

Silicone heat-insulating and non-slip coasters have many advantages due to their unique material properties and design, making them a popular choice in modern homes and commercial places. Here are some of the main advantages of silicone heat-insulating and non-slip coasters:

1. High temperature resistance

Silicone coasters are usually made of food-grade silicone, which has high high temperature resistance and can withstand common hot drinks or hot foods without deformation or fading. This feature allows silicone coasters to effectively protect the table during use and prevent burns caused by hot drinks.

2. Non-slip design

Many silicone coasters have a non-slip design. The surface texture or raised structure can effectively prevent the cup from sliding on the table, improving the stability of use. Especially in the case of children or pets in the family, the non-slip design of silicone coasters can effectively reduce the possibility of accidents.

3. Easy to clean

Silicone coasters have good dirt resistance and easy to clean. They can usually be cleaned by gently wiping with water or detergent, and are not easy to stain. Compared with traditional paper coasters or cloth coasters, silicone coasters are more convenient and faster, saving time and effort.

4. Versatility

In addition to being used as coasters, silicone coasters have a variety of other uses. For example, they can be used as bottle openers, stirring sticks, or supports covered with plastic wrap, which increases their practicality and value.

5. Aesthetics

Silicone coasters are usually available in a variety of colors and shapes, and you can choose the right style according to your personal preferences or home style. For example, this light luxury cardboard silicone coaster.

6. Environmentally friendly and non-toxic

Silicone coasters are made of food-grade silicone, which is environmentally friendly and non-toxic. They can directly contact the skin without any harm. The safety of this material makes it an ideal choice for home and office environments.

7. Durable, wear-resistant, waterproof and anti-fouling

Silicone coasters have a long service life and are not easy to age and deform in high temperature environments. Its durability means that users can use it for a long time without having to replace it frequently.

8. Temperature adaptability

Silicone coasters can be used in a wide range of temperatures, from low temperatures of -40°C to high temperatures of 230°C, which makes them suitable for a variety of environments, including ovens, microwaves, dishwashers, and refrigerators.

Where is the application for Silicone Coasters VS Silicone Trivets?

Silicone coasters are preferred where is the Coffee table in the living room.

Thermal insulation silicone pads are preferred when dining table.

Thermal insulation silicone trivets are more commonly used in Outdoor picnic/camping:

Office desks and conference tables: coasters are more commonly used, and small thermal insulation pads can also be used to place thermos cups.

How to produce Silicone Coasters VS Silicone Trivets?

Silicone pads are widely used in medical, maternal and child, kitchenware, electronics and other fields due to their high temperature resistance, non-toxic and environmentally friendly, strong flexibility and other characteristics. However, behind the seemingly simple silicone coasters and silicone insulation pads, they need to go through a complex production process. From raw material ratio to finished product testing, omissions in each link may cause product cracking, deformation or substandard performance. So, what production steps does a qualified silicone pad have to go through?

1. Raw material selection and pretreatment

The quality of silicone pads depends first on the raw materials. Manufacturers need to choose different grades of silicone raw rubber (such as food grade, medical grade or industrial grade) according to the purpose of the product, and add color glue, vulcanizer, plasticizer and other auxiliary materials.

Raw material testing: Verify the performance of the raw rubber through hardness testing and tensile strength testing to ensure compliance with industry standards (such as FDA, LFGB certification).

Pretreatment process: Some high-precision products need to filter and remove impurities from the raw rubber, or use a vacuum degassing machine to remove bubbles in the rubber to avoid pore defects in the finished product.

2. Mixing and color matching

Fully mixing the original rubber and additives is a key step to ensure product uniformity:

Internal mixer mixing: In a closed internal mixer, the rubber, vulcanizer and color paste are evenly blended through high-temperature shear force. The temperature is usually controlled at 40-60℃ to avoid premature vulcanization.

Color matching accuracy: Medical or food contact products require the use of inorganic pigments, and the color difference is calibrated by a spectrophotometer to ensure color consistency between batches.

3. Mold design and molding

The molding process directly affects the appearance and dimensional accuracy of the product:

Mold processing: According to the 3D design drawings, CNC processing or EDM engraving is used to make steel molds. The error of precision molds must be controlled within ±0.02mm.

Molding method selection:

Compression molding: put the rubber into the mold and pressurize and heat it through a flat vulcanizer. It is suitable for simple seals, buttons, etc.;

Liquid injection molding (LSR): inject liquid silicone into the mold cavity, suitable for the production of special-shaped parts and thin-walled products.

Drip molding: through a liquid drip machine, first drip the liquid silicone according to the pattern and color required by the silicone pad, and then vulcanize it at high temperature. Put solid silicone again on the vulcanized color, and then pressurize and heat it with a flat vulcanizer to vulcanize the silicone pad required for molding.

4. Vulcanization and shaping

Vulcanization is the core link of the cross-linking of silicone molecular chains and determines the physical and chemical properties of the product:

One-stage vulcanization: at a high temperature of 120-180℃, the rubber is initially shaped by molding or drying. The time is adjusted according to the thickness of the product (usually 5-15 minutes).

Two-stage vulcanization: high-performance products (such as high-temperature resistant gaskets) are baked twice (200-250℃) to further eliminate volatile substances and improve tear resistance.

5. Post-processing and surface modification

The silicone pad after molding needs to go through multiple finishing processes:

Deburring: Manual or frozen deburring machine removes the overflow glue at the mold parting line;

Surface treatment: Add product texture or logo through sandblasting, laser engraving or UV printing, and medical catheters need plasma treatment to improve surface hydrophilicity;

Special coating: Some electronic accessories need to be sprayed with antistatic coating, and kitchenware products can add antibacterial coating.

6. Quality Inspection and Performance Testing

A strict inspection system is the last line of defense for product safety:

Appearance inspection: Use industrial cameras or manual visual inspection to check for defects such as missing materials, stains, and bubbles;

Physical performance test: Use a tensile machine to test tensile strength (≥8MPa) and a hardness tester to measure Shore hardness (commonly 20-80A);

Chemical safety verification: Food-grade products must pass migration tests (detection of heavy metals and plasticizer residues.

7. Packaging

Z.S.R Group can customize packaging according to customer requirements, including PET boxes, color cards, color boxes, gift boxes, etc. We provide you with customized packaging solutions for all products. We will serve as a resource and extension of your company, helping you from start to finish and saving you time and money.

How Much of the silicone coaster and silicone trivets?

- The silicone coasters cost is around 0.9-2USD/pcs.

- The silicone trivets cost is around 3-6 USD/pcs

How to choose the silicone coaster and silicone trivets?

How to control the quality of silicone coasters and silicone trivets?

The quality control of silicone coasters needs to be strictly controlled from raw materials, production processes, testing processes and other links. The specific measures are as follows:

Raw material control

Select materials with LFGB/FDA certification for the production of silicone coasters and insulation pads.

Production process optimization

Mixing process: Use a double-rotor internal mixer, the initial temperature is 20-25℃, the mixing time is 8-12 minutes, and the discharge temperature is ≤50℃.

Molding and vulcanization: The mold temperature is set according to the process type (solid silicone 160-180℃, liquid silicone 170-210℃), and the PLC control system is used to monitor the vulcanization temperature (±2℃), pressure (8-15 MPa) and time (t90+10%) in real time.

Post-processing: Improve product durability through deburring, cleaning, drying and other steps.

Quality inspection and aging test Physical properties: Test hardness, tensile strength, tear strength, compression permanent deformation and other indicators.

Chemical properties: Test chemical solvent resistance, weather resistance and UV aging resistance.

Safety performance: Ensure non-toxicity, non-irritation, and meet food safety standards or medical grade requirements.

Appearance inspection: The surface should be free of bubbles, impurities or cracks, and the color should be uniform

Thickness deviation detection

Heat and water resistance test: Coaster test -50~150°C hot and cold cycle, insulation pad test to 250°C;

Anti-slip and wear resistance evaluation: American standard friction coefficient test;

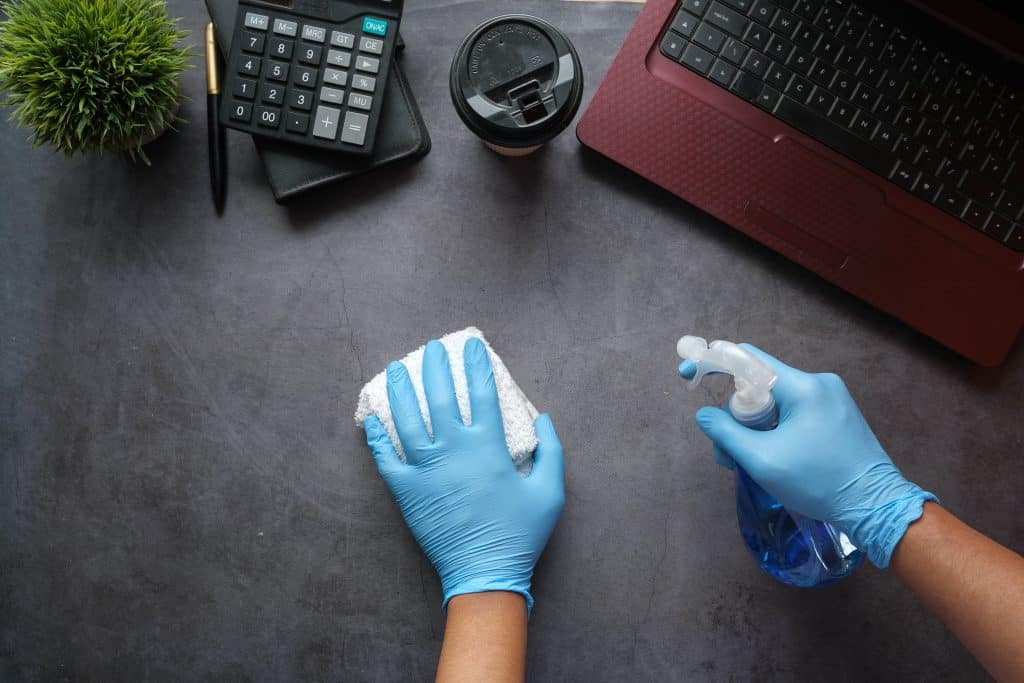

How to clean silicone coasters and silicone trivets?

Soak the silicone coaster in warm water (40-50℃) for 10-15 minutes to soften the stains.

After soaking, use a soft cloth or sponge to dip in a neutral detergent (such as dishwashing liquid) and gently wipe the surface, focusing on cleaning gaps and stubborn stains.

After rinsing with clean water, place it in a ventilated place to dry naturally, avoiding direct sunlight or high-temperature drying.

Grease stains/odor: Wipe with alcohol or white vinegar, then rinse with clean water.

Yellowing problem: Mix white vinegar and warm water in a ratio of 1:3, soak for 30 minutes and then wash.

Mold spots: First wipe the surface mold spots with a damp cloth, then soak in diluted bleach and wash

Silicone Trivets: dishwasher safe at high temperature, pots and pans must be cooled before cleaning.

More FAQs

Summary

Silicone coasters are suitable for daily beverage stain prevention, anti-slip and daily decoration;

Silicone Trivets can carry hot pots, protect the desktop at high temperature, and are anti-slip and high temperature resistant;

Correct selection is based on size, heat resistance, thickness, safety, design, aesthetics, cleaning convenience and price-effectiveness.

Different selling points should be set for different channels: home, coffee shop, gift or commercial kitchen, emphasizing:

“Waterproof and heat-resistant, zero difficulty in cleaning”

“Safe and high temperature, light and thin, stackable”

“Customized design, enhance brand style”

Looking forward to providing you with a one-stop solution from selection to customization, please feel free to contact Z.S.R!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.