Can silicone withstand high temperatures?

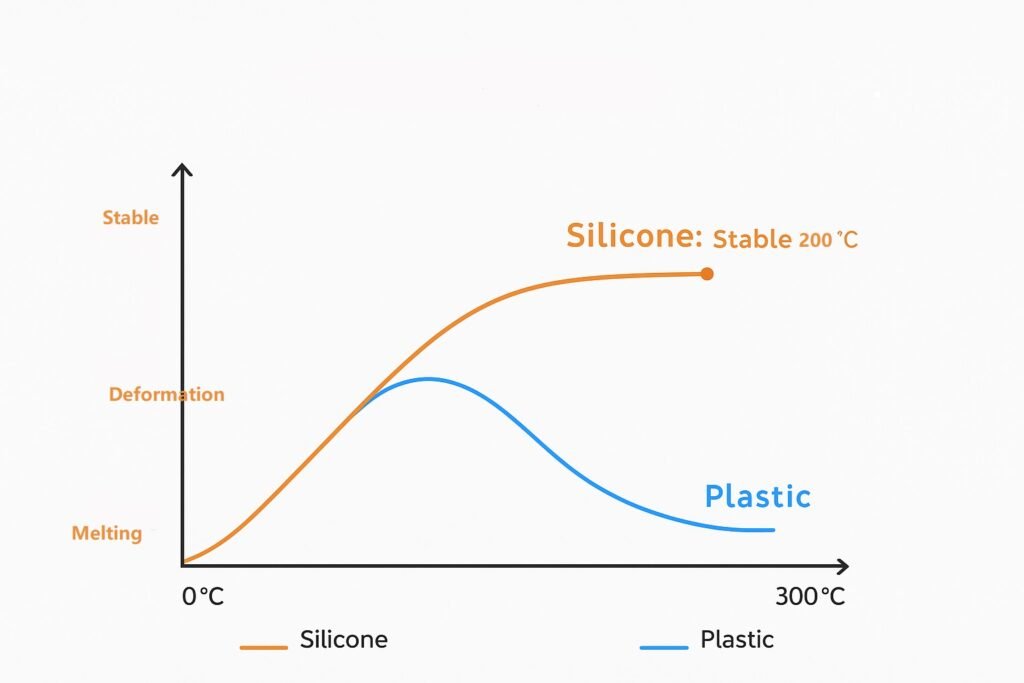

With a temperature resistance of -60°C to 250°C, silicone is widely used in the food, medical, industrial, automotive, and electronics industries. However, many customers remain concerned: Can silicone truly withstand high temperatures? Will it release harmful substances?

The truth is: Due to its unique molecular structure, silicone exhibits high-temperature resistance far exceeding that of ordinary plastics and rubbers, reaching temperatures as high as 300°C. Different grades of silicone are suitable for a variety of applications, including food, medical, industrial, automotive, and electronics. This article will comprehensively explain silicone’s high-temperature resistance and its application value.

What is silicone? Can it withstand high temperatures?

Silicone rubber is a polymeric elastic material with a silicon-oxygen bond as its backbone. The main chain is composed of alternating silicon and oxygen atoms (—Si—O—Si—), with side chains linked to carbon-hydrogen or organic groups (such as methyl and vinyl groups) that replace carbon-hydrogen. Its high-temperature resistance stems primarily from the high binding energy of the Si–O bond (silicon-oxygen bond), which is significantly more stable than the carbon chains of common plastics (such as PP and PE).

Its molecular structure combines the properties of both organic and inorganic materials, resulting in excellent resistance to high temperatures, weathering, UV rays, and ozone. It is generally non-toxic, odorless, and chemically inert. Silicone rubber has outstanding heat resistance.

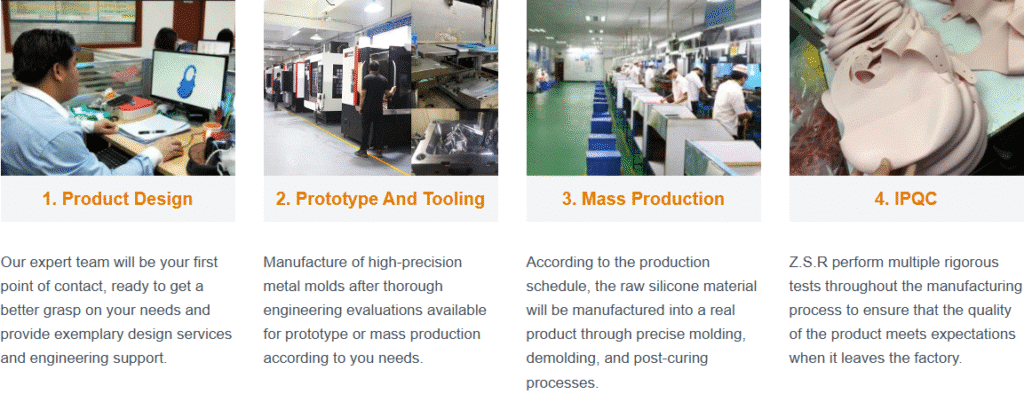

Z.S.R is a silicone products fabrication factory. From initial high-temperature silicone products resistant design to final delivery, we provide comprehensive one stop services. You do not need deal with multiple suppliers or coordinate different aspects of the project yourself. Simplify the entire process and save your valuable time.

Custom Silicone Products | OEM/ODM Service

Why is silicone resistant to high temperatures?

The Si-O bond has a high binding energy of 452 kJ/mol, while the C-C bond has a low energy of only 348 kJ/mol. Then Silicone has a low thermal conductivity. This means it transfers heat at a much slower rate than some other materials, leading to excellent heat resistance. Excellent Thermal Stability, The molecular chain is not easily broken when heated, thus maintaining stable physical properties at high temperatures. It can also be described as having good ‘thermal stability’ meaning it retains its structure and properties over a wide temperature range.

High Inertness: It does not react with most chemicals and does not produce toxic decomposition products at high temperatures.

Contact Z.S.R to create durable, compliant, brand-ready high-temperature resistance silicone solutions.

Who cares about silicone’s high-temperature resistance?

Kitchenware and tableware brands, whose products all use food-grade silicone (such as tableware and drinking glasses), must pass high-temperature testing (180-200°C) to ensure that no harmful substances are released when used in boiling water or microwave ovens. They are concerned about the safety and reliability of their silicone products during heating, steaming, and baking.

Medical industry clients, whose medical silicone products must meet high-temperature sterilization requirements (such as baking at 220°C) and are commonly used in the manufacture of medical devices, and whose non-toxic properties ensure medical safety, are concerned about the impact of high-temperature sterilization and disinfection on the performance of silicone products.

Automotive and industrial clients: Silicone is commonly used in the manufacture of sealing rings, rubber rollers, and high-temperature seals. It is suitable for mechanical seals, electronic and electrical insulation, automotive parts, and sealing materials for aircraft, rockets, and other aircraft. Failure of seals at high temperatures is a key factor in ensuring safety.

Power and electronics industry clients: For electrical insulation and heat dissipation, silicone rubber’s high-temperature stability makes it an ideal insulating material for high-voltage cable accessories. It can maintain electrical insulation performance in high-temperature environments, ensuring safe power transmission. Whether silicone can withstand high-temperature operation is crucial to the stability of these clients and their products.

Consumers are also very concerned because if we need to use silicone products, we are concerned about whether silicone products will become toxic at high temperatures.

When and where is the high temperature resistance of silicone required?

Home kitchen or food processing applications: kitchen utensils, baking molds

Baby products: require high-temperature sterilization. Food-grade silicone certified by FDA and LFGB, focusing on safety

Medical applications, hospitals and laboratories: 121°C autoclave sterilization. Pay attention to whether the material is aging or yellowing after high temperature disinfection

Industrial applications: high-temperature equipment, high-temperature piping, seals, and gaskets. More emphasis on temperature resistance, aging resistance and tear resistance.

Automotive and aerospace industries: automotive engine and electronic component seals, lighting seals, and sealing materials used in aircraft, rockets, and another spacecraft.

As a silicone molding factory in China with 16 years, Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(32sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc. Custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality silicone products for different industry application from industrial, consumer, commercial to medical.

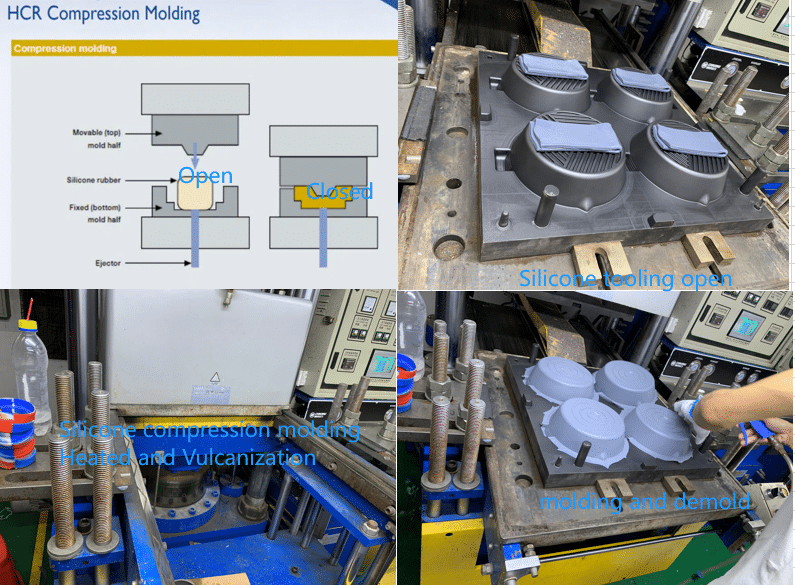

How are high-temperature-resistant silicone products produced?

The process of silicone products produced involves several steps from silicone products Design Concept, Material Selection Choose high-temperature silicone raw materials (such as Wacker and Dow Corning), Prototypes Development, logo Printing or Branding, Silicone Tooling and Mold, Material Mixing and Preparation, Silicone Molding and Shaping(Compression molding or liquid silicone injection molding (LSR) to ensure uniform curing.), Curing and Cooling, Demolding, Quality Control, Printing,Cleaning and Packaging to shipping for creating personalized and branded silicone molded products or other silicone products.

Additive Control: Appropriately add high-temperature-resistant additives to ensure long-term stability. Please get the below picture to know more.

Please go through the How to make silicone products and how to put the logo on silicone products to know more details.

How much does high-temperature-resistant silicone material cost?

- Ordinary solid silicone: Approximately $2-4 USD/kg

- Food-grade silicone: Approximately $5-8 USD/kg

- Medical-grade silicone: $10-20 USD/kg

Price is closely related to the temperature resistance grade and certification standards (FDA, LFGB, USP VI).

How to choose high-temperature-resistant silicone?

Based on the application temperature range (e.g., choose ordinary silicone for temperatures under 200°C, and fluoro silicone for temperatures above 250°C).

Based on industry standards (food grade, medical grade, industrial grade).

Based on service life (long-term vs. short-term high-temperature conditions).

Z.S.R is the partner choice of custom silicone products for leading silicone products brands and retailers. Recognized for delivering innovative molded silicone products, silicone products manufacturing expertise, and silicone technical solutions to meet your brand’s functional and design needs. We will recommend the suitable temperature silicone material for your silicone projects, just contact our expert.

How to control the quality high-temperature performance of silicone?

Strictly control the raw material formula.

Avoid over- or under-curing during the production process.

Avoid prolonged contact with oils, dirt, and organic solvents before use.

Z.S.R Group understand the importance of quality, our whole-process quality control system ensures that our customers can receive the qualified products as they approved before mass production. Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the qualified Silicone cups as the prototype they approved before mass production. Contact us to contract your silicone project to this reliable partner.

How to clean high-temperature silicone products?

More FAQs

Will silicone melt at high temperatures?

No, silicone doesn’t melt like plastic. Instead, it may gradually decompose and carbonize when the temperature exceeds its limit.

Is silicone oven-safe?

Food-grade silicone baking molds can safely withstand temperatures up to 220°C and are perfectly oven-safe.

Which is more heat-resistant, silicone or plastic?

Silicone is more heat-resistant. Most plastics deform at around 100°C, while silicone can withstand temperatures above 200°C.

Does silicone have an odor at high temperatures?

High-quality silicone has no noticeable odor, while inferior silicone may release an unpleasant odor. Choose a reputable manufacturer.

Summary

With the increasing demand for environmentally friendly and high-performance materials, high-temperature silicone will continue to maintain strong growth potential in the global market. When choosing high-temperature silicone products, brands and customers are most concerned about safety, performance stability, and durability. To address these concerns, Z.S.R. offers FDA, LFGB, third-party SGS, and Interk certifications for silicone products and materials, as well as material optimization and process control to address these issues.

If you need high-temperature silicone material selection and process guidance for specific industry applications, please contact Z.S.R ’s material and our molding experts. We will recommend suitable materials based on the application scenarios and needs of your silicone project to empower your silicone project succeed.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.