Silicone Melting Temperature

As an industry expert with 24 years of experience in the silicone products industry, I’ve encountered many engineers, designers, and purchasing professionals in industries like medical, automotive, consumer electronics, and maternity products who are increasingly choosing silicone materials to manufacture their products. Due to their growing demand for high-performance materials, silicone, due to its excellent thermal stability and flexibility, is widely used in harsh environments. However, when purchasing silicone products or developing related components, they often ask:

“What is the melting point of silicone?”

“How high a temperature can it withstand?”

“How do I control its melting temperature?”

This article will comprehensively analyze how silicone’s melting point, thermal stability range, and material composition affect its performance, as well as how to “control” its high-temperature resistance through process and material adjustments. This will provide a professional understanding of the role of this critical parameter in product design and use.

What is the melting temperature of silicone?

In reality, silicone doesn’t actually melt like plastic. It’s a cross-linked thermoset polymer with no clear melting point. Unlike plastic, it doesn’t melt into a liquid form at high temperatures. Instead, it decomposes and gradually carbonizes.

The typical thermal decomposition temperature range for silicone is 200°C to 300°C (392–572°F). Above this range, it begins to decompose.

However, the thermal decomposition temperature varies depending on the grade of silicone. High-temperature silicones: Certain specialty silicones (such as fluorosilicone and HTV/LSR) remain stable above 300°C and can even withstand temperatures exceeding 350°C for short periods.

Silicone’s flammability limit: The autoignition point is approximately 450°C, but silicone is easily self-extinguished, and the combustion product is odorless silicon dioxide (white ash).

Therefore, the “melting temperature” we commonly refer to should more accurately be referred to as the “thermal decomposition starting temperature” or “maximum temperature resistance limit” of silicone or silicone products. For more information on silicone, please visit https://consumersiliconeproducts.com/custom-silicone-oem-odm-service

Why is silicone’s melting point so important?

The silicone kitchen baking molds we manufacture and design must withstand temperatures exceeding 200°C without melting or deforming. Automotive/electronic seals must withstand high engine temperatures, requiring a thermal decomposition point above 250°C. Medical devices must be sterilizable (121°C-134°C) without softening or discoloring. These products all involve high-temperature exposure, so during the product development phase, designers must consider material selection to ensure it does not degrade during high-temperature molding, welding, drying, or sterilization. They must also consider the product’s market, as safety regulations, such as those from the FDA and LFGB, have strict temperature resistance requirements.

Who is most concerned about silicone melting temperature?

Based on my years of industry experience and my analysis of the audience asking these questions, the most concerned are kitchenware and maternity product brands, as well as cross-border e-commerce practitioners. They need to highlight “high-temperature resistance” and “oven-safe” properties when selecting and marketing their products.

Next in line are product managers of these kitchenware and maternity brands, as well as wholesalers and distributors. They need to evaluate whether the silicone formula used by suppliers meets end-user needs.

The third group of people concerned are likely designers, engineers, and material developers in the medical and automotive parts industries. They focus on silicone materials’ thermal stability, decomposition pathways, and compatibility with molding processes to select the right silicone raw materials for their projects.

Which category do you fall into?

When is silicone’s melting point particularly important to consider?

According to the silicone product development process, silicone melting point needs to be considered during…

At Z.S.R, we strictly control the silicone product production process to ensure that the products meet quality standards and are delivered to you.

According to the development process for silicone products, which applications require this parameter?

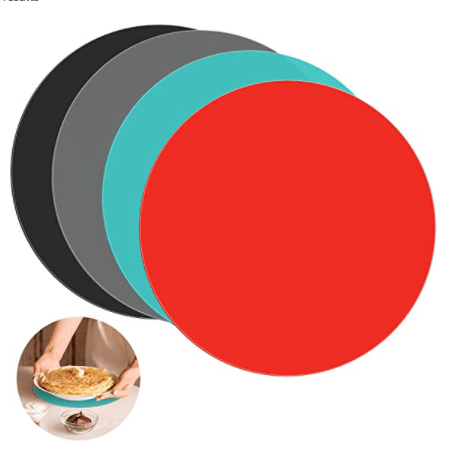

Kitchenware applications:

For example, silicone cake molds, silicone spatulas, silicone pressure cookers, and other silicone seals used for cooking require high temperatures.

Therefore, silicone brands for kitchenware products should consider the melting point of silicone when selecting materials.

When silicone is used in high-temperature applications (such as automotive engine parts, industrial seals, and electronic gaskets), its melting point must be higher than the operating temperature to prevent softening or deformation.

Silicone products used in baby products:

Because silicone pacifiers and teethers require high-temperature sterilization, silicone containers and bowls are exposed to hot food, require high-temperature cleaning, or require sterilization in a sterilizer, the silicone’s heat resistance is important.

Medical silicone requires high-temperature sterilization (such as 120°C steam sterilization), but the material’s heat resistance must be maintained.

How to evaluate the heat resistance of silicone materials?

From the above information, we can see that silicone’s temperature resistance is crucial for selecting materials for our brand and process. So, how do we evaluate silicone’s temperature resistance? Generally, we consider the following aspects when selecting and evaluating silicone:

- First, you can check the MSDS/Technical Data Sheet (TDS) of the silicone raw material: high-quality silicone suppliers typically indicate the temperature resistance range.

- Second, you can perform high-temperature aging tests on silicone products: Hot air aging test: This test subjects silicone samples to a high-temperature environment (such as 150°C or 200°C) and evaluates heat resistance by measuring changes in tensile strength, elongation at break, and other parameters. Ordinary silicone typically has a temperature resistance range of -55°C to 250°C, while food-grade silicone can reach temperatures between 250°C and 300°C. Performance retention after aging: For example, tensile strength retention must be ≥80%, and elongation retention must be ≥60%.

- Third, you can perform UV aging test on silicone: This test simulates sunlight exposure (such as UVA-340 and UVB-313) to evaluate changes in color, gloss, and mechanical properties. Finally, we can outsource third-party certification assessments to ensure our silicone products meet thermal safety standards such as FDA 21 CFR 177.2600, LFGB, GB/T 3512-2014, and UL 94V-0.

All Z.S.R ‘s silicone products are guaranteed to be high-temperature and aging-resistant.

What is the price of high-temperature, heat-resistant silicone products?

The price of silicone raw materials depends on the formulation and additives. The following is a typical range (per ton):

At Z.S.R, you can find the best prices for your dream products.

How to “control” silicone’s melting temperature (actually, thermal stability)?

Although silicone doesn’t have a true “melting point,” we can improve or control its high-temperature performance through the following methods:

1. Choose the right silicone formula.

Different silicone types have different structures and thermal stability.

If your product is for kitchenware or industrial seals, we recommend high-temperature silicone (HTV) or fluorosilicone (FVMQ).

If your product requires complex injection molding, we recommend heat-resistant liquid silicone (LSR).

2. Add heat stabilizers.

You can add:

Inorganic heat-resistant additives such as iron oxide and aluminum oxide;

Fillers such as fumed silica (silica) to increase the cure density and pyrolysis temperature;

Specialized flame retardants to enhance its self-extinguishing properties.

3. Optimize the vulcanization process (cross-linking structure).

Using a platinum catalyst system is more suitable for high-temperature applications than traditional peroxides and produces less residue.

Increasing cross-linking density: Adjusting the cross-linker dosage, extending the reaction time, and increasing the reaction temperature will prevent silicone products from softening, sagging, or deforming at high temperatures.

4. Control the ambient operating temperature.

Even for high-temperature-resistant silicone, it is recommended to keep the operating temperature below its maximum limit by 20°C for extended periods to prolong its life.

Insulation or metal protection can be incorporated into the product structure to improve its adaptability to hot environments.

Silicone does not “melt” in the traditional sense; instead, it slowly decomposes at high temperatures. Its temperature resistance can be adjusted and controlled by selecting the material type, adding additives, and optimizing the vulcanization process.

Understanding and controlling the melting temperature of silicone is key to the safe, reliable, and long-term use of products in high-temperature environments.

Silicone’s “Melting Point” Isn’t a Melting Point, But It’s Critical

In summary, while silicone doesn’t have a traditional melting point, its thermal decomposition temperature and high-temperature resistance are key material selection criteria, directly impacting a product’s stability and service life in high-temperature environments. A scientific understanding of the material not only aids in product quality control but also strengthens brand differentiation in your marketing efforts.

We provide comprehensive services, from material selection and mold design to performance testing. Please contact Z.S.R for samples or professional advice!

Custom Silicone Products | OEM/ODM Service

More FAQs

Summary

Silicone doesn’t “melt” in the traditional sense; instead, it slowly decomposes at high temperatures. Its temperature resistance can be adjusted and controlled by selecting the right material, adding additives, and optimizing the vulcanization process.

Understanding and controlling the melting temperature of silicone is key to ensuring safe, reliable, and long-lasting use in high-temperature environments.

Do you need a custom silicone product that’s durable and designed for high temperatures?

Z.S.R. provides comprehensive services, from material selection and mold design to performance testing. Please contact Z.S.R for samples or professional advice!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.