TPE vs. Silicone: Which Elastomer is Right for Your Product?

Today’s market demands for material safety, durability, and tactile feel are constantly increasing, with TPE (thermoplastic elastomer) and silicone (silicone/gel) becoming mainstream elastic materials. However, significant differences exist between the two in terms of thermal performance, processing, and environmental friendliness, often leaving designers, product managers, product development managers, and buyers struggling with the question of which is best. This article provides a clear comparison of the two, focusing on definitions, advantages, and application areas, to provide a reference for material selection:

What is TPE?

TPE is a thermoplastic elastomer that combines plastic processability with rubber elasticity.

It is suitable for injection molding, extrusion and other processes and is recyclable.

What is silicone?

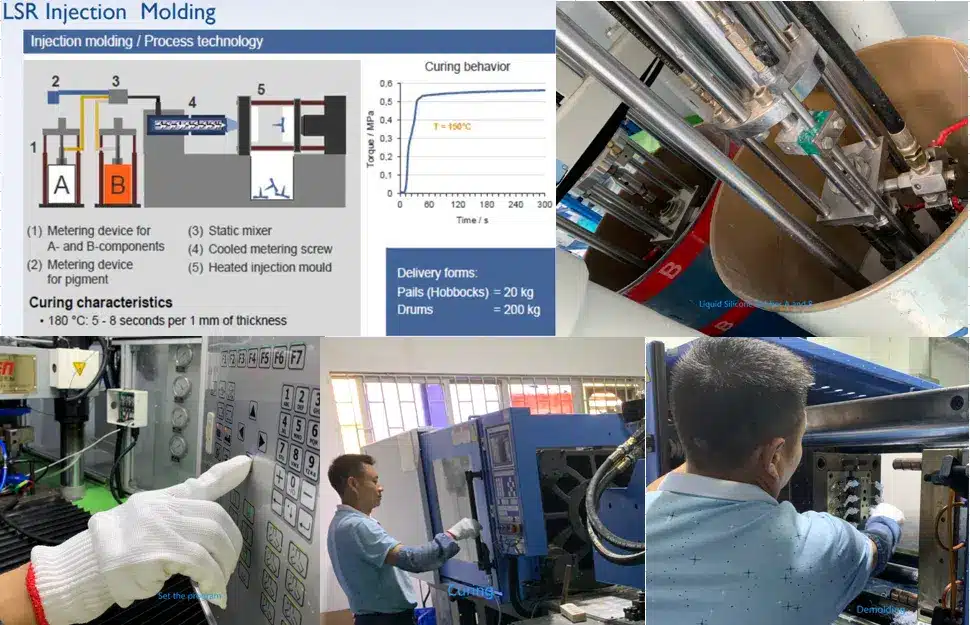

Silicone is a thermosetting elastomer (such as liquid silicone rubber (LSR)).

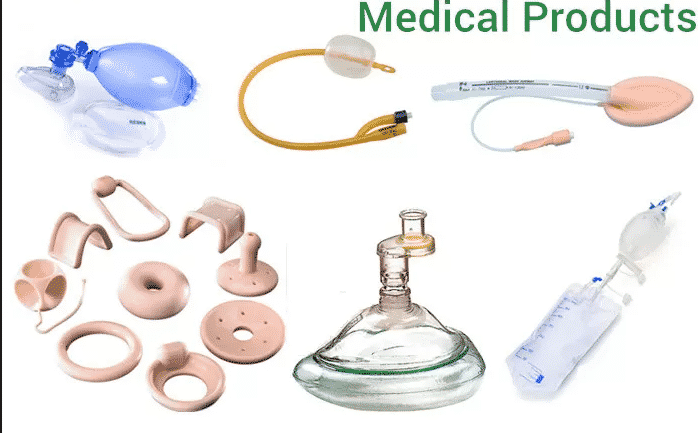

It has excellent thermal stability and biocompatibility and is widely used in high-end medical, maternity, and kitchenware applications.

What are the main differences between silicone and TPE?

Different chemical structures:

The main chain of silicone is composed of silicon-oxygen bonds (Si-O), and the side chains are mostly methyl groups (CH₃), which have high stability and weather resistance; the main chain of TPE is carbon-carbon bonds (C-C), which has a more flexible structure and is suitable for injection molding.

Performance comparison:

- Temperature Resistance:

- Silicone can withstand temperatures ranging from -60°C to +250°C, even reaching 450°C for short periods; TPE only withstands temperatures of approximately -30°C to +80°C (medical-grade versions can reach 135°C).

- Recyclability:

- TPE can be melt-reformed and recycled; silicone is cross-linked and non-recyclable.

- Wear and Chemical Resistance:

- TPE is more wear-resistant and oil-resistant; silicone is heat-resistant, chemically stable, and biocompatible. Silicone is commonly used in medical devices, while TPE requires additional processing before use in products that come into contact with the human body.

Processing Differences:

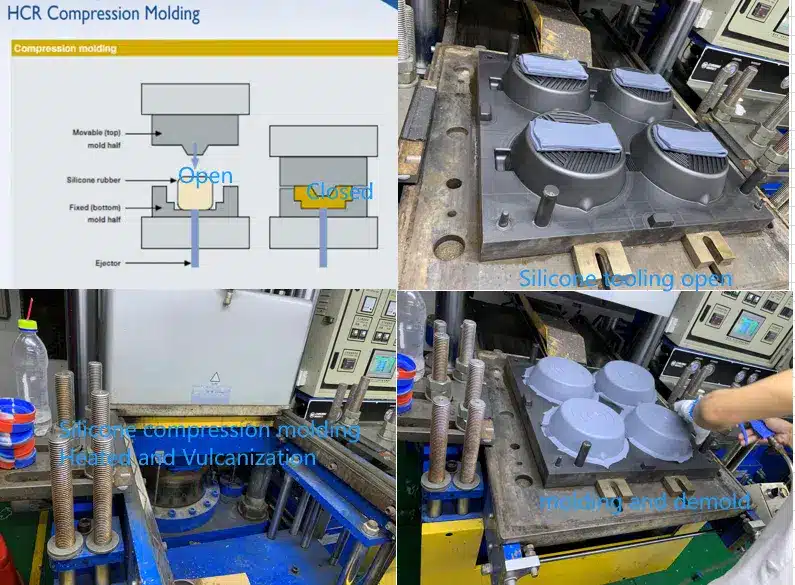

- Silicone requires high-temperature vulcanization and molding, which is complex, non-recyclable, and leads to high production costs.

- TPE does not require vulcanization and can be directly injection molded or extruded. Its waste is recyclable and offers higher production efficiency.

Who is most concerned about the differences between silicone and TPE?

Purchasing/product managers in consumer electronics, toys, kitchenware, maternity products, medical supplies, and sports equipment;

Product designers and engineers who use these materials: They need to match material properties and manufacturing processes; and they seek alternatives to soft materials.

Brands and buyers who sell products made from these materials: They prioritize cost, environmental performance, and differentiation.

End consumers: They prioritize product safety, feel, environmentally sensitive users, mothers and infants, and consumers who are concerned about the tactile or safety aspects of materials; for example, durability, such as in kitchenware/maternity products.

IP brands/creative cultural and creative companies: They focus on product styling, color, tactile quality, and environmental considerations.

If you prioritize cost-effectiveness, safety, and tactile performance in silicone products, Z.S.R. is your best choice.

When should you consider silicone vs. TPE?

- High-temperature applications: kitchen utensils, medical devices, and high-temperature seals;

- Environmentally friendly recycling requirements: sustainable packaging, disposable products, etc.;

- High-precision or specialized material products: Requires softness, skin-friendliness, and chemical stability.

Where are silicone and TPE suitable?

- TPE is more suitable for seals, electric toothbrush handles, insoles, shock absorbers, cultural and creative toys/blind box accessories, non-slip mats/fitness resistance bands

- Silicone is suitable for pacifiers, baby teethers, kitchen utensils, medical devices, baking supplies, and microwaveable utensils.

Silicone vs. TPE: How to choose the right material?

1. First, determine the product’s operating temperature: Silicone can withstand temperatures of 200-250°C for extended periods, while TPE can only withstand 70-80°C. For example, when an electrical seal needs to operate near 100°C, silicone is more suitable. When the product needs to operate at temperatures above 80°C, silicone can withstand 121°C steam sterilization and maintains stable performance after repeated sterilization. TPE requires a special formula to achieve the same temperature resistance and is susceptible to aging under prolonged high temperatures. For products used in high-temperature environments or requiring sterilization, choose silicone.

2.Silicone has excellent deformation recovery and virtually no permanent deformation.

TPE is prone to irreversible deformation under sustained stress and is unsuitable for products that require repeated opening and closing, such as seals and plugs.

For products that prioritize “precision molds and biosafety certification,” silicone should be chosen.

3. Silicone passes tests for oils like olive oil, while TPE (with a hardness below 70A) cannot.

It is suitable for food-grade seals or components that come into contact with oils and fats.

4. In the medical device field:

Silicone has superior biocompatibility and is widely certified by medical institutions such as ISO 10993, making it suitable for implants or devices that come into contact with the human body.

How much do silicone and TPE cost and price?

Silicone Materials:

TPE:

Medical/food-grade silicone: The highest cost, but can enhance brand premium and product value. Recently, due to the impact of import tariffs on platinum catalysts, the cost of liquid silicone raw materials has increased by 18%, further pushing up the price of end products (for example, silicone dinner plates have increased by 12%-15%).

TPE: The price of standard TPE ranges from 14,000 to 28,000 yuan per ton, lower than silicone. Specialty types (such as food-grade TPE) may be slightly more expensive, but overall they still offer cost advantages.

Silicone products: Prices are generally higher than TPE. High-end silicone products (such as sex dolls) used to cost tens of thousands of yuan due to high technical barriers and raw material costs.

How do we control the quality of TPE and silicone products?

Silicone products:

First, we control the product design. After the customer receives the product, our engineering team will conduct a Design for Manufacturing (DFM) evaluation of the silicone product design and provide recommendations that are suitable for mass production and meet customer requirements.

Second, we control the incoming raw materials. We purchase FDA/LFGB-certified silicone raw materials and conduct incoming material inspections to check their hardness, purity, color, and other factors. We also mark and label them to ensure that the raw materials used in production are qualified.

Third, Mold Design and Production: We design the silicone molds for production based on the customer’s product requirements. We use vacuum degassing and controlled injection volume to reduce external bubbles, control the mold gap, and effectively remove glue to control the dimensional accuracy of the silicone product. Fluorine treatment/mold release spraying can improve mold sticking.

Fourth,during production, we add anti-yellowing agents or choose highly transparent formulas to enhance the aging resistance of silicone products. Adding reinforcements/cross-linking treatments achieves the desired tensile strength. Furthermore, visual inspections, routine inspections, and 100% full inspections ensure that all silicone products leave the factory and meet quality standards.

TPE Products:

- Select TPE materials that are REACH and ROHS compliant.

- Mold temperature control, surface polishing, and optimized mold venting groove design minimize external bubbles and mold sticking.

- Adjust injection speed and hold time, use UV- and oil-resistant TPEs, and select highly elastic SEBS-based TPEs to achieve product dimensional accuracy, aging resistance, and tensile strength.

Custom Silicone Products | OEM/ODM Service

More FAQs

Summary

- TPE is suitable for low- to medium-temperature applications where cost, processing efficiency, and good feel are key.

- Silicone is a high-end option for high-temperature, safety, and chemical resistance.

Choosing the right material can enhance product performance, customer trust, and brand value. Choosing the right material can enhance product performance, customer trust, and brand value. For more information, visit Z.S.R.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.