The Composition of Silicone Leather

1. What is silicone Leather?

Silicone leather, as the name suggests, is a synthetic leather made of silicone material. The silicone leather is silicone coated fabric, similar to PVC (vinyls) and polyurethane (PU) coated fabrics. Silica gel, that is, silicone rubber, is a kind of polymer elastic material, with good high temperature resistance, cold resistance, corrosion resistance, wear resistance and other properties, but also has good elasticity and softness. is widely used in various fields because of its excellent physical and chemical properties. Silicone leather, as an application form of silicone, combines the advantages of silicone with the texture of leather and becomes a new type of material. It is non-toxic durability and eco-friendliness than other materials like vegan PU leather or vegan faux leather due to the features of silicone.

Z.S.R is a leading silicone leather manufacture and wholesale in China. Z.S.R team work with the different industry product fabric selection designers, product developer, R&D engineer, product manager together designs and make the Silicone leather fabric in an assortment of tear strength, hydrolysis resistance, waterproof and stain resistant, Wear resistant and scratch resistant, Heat/Cold temperature resistance, easy to clean, inherently stain resistant, and bleach cleanable for the toughest messes, bespoke base layer, colors and texture to empower their furniture, car seat cover, marine boat, handbag, mobility, fashion, wearable electronics and interior design upholstery product’s project success in design and functional requirements.

2. Overview of the Composition of Silicone Leather, the Status and Characteristics of Its Main Components

Silicone leather is a synthetic material mainly composed of silicone polymers, fabrics and cross-linking agents. Silicone polymers are the main component of silicone leather, accounting for 60-80% of the total volume. They are composed of silicon atoms, carbon, oxygen, hydrogen and other elements, which can control their physical and chemical properties and are used for dyeing and finishing.

Fillers such as cellulose, sodium cellulose acid, calcium carbonate, etc. are used to improve the strength, hardness, wear resistance and fading resistance of leather, while improving softness and feel. Cross-linking agents enable silicone polymers to form a three-dimensional physical network structure, enhancing wear resistance, fading resistance and high temperature resistance, but the amount added should not be too much, so as not to affect the softness and feel of the leather.

In addition, silicone leather is usually made of fabric as the base and coated with silicone polymers. Its preparation process includes dry process, and leather of various colors can be customized to meet different needs. Its main components are silica and silicone substances, and in the production process of silicone leather, silica as an important additive, plays a vital role:

- Enhanced performance: Silica, as an inorganic filler, can significantly improve the mechanical properties of silicone leather. By combining with the silicone substrate, it increases the hardness, wear resistance and tensile strength of the material, making the silicone leather more durable in practical applications.

- Improve appearance: The addition of silica can also improve the appearance of silicone leather. It can make the surface of silicone leather smoother and more delicate, reduce pores and defects, and improve the beauty of the product. At the same time, the particle size and distribution of silica also affect the gloss and color of silicone leather, making the product more attractive.

- Prolong the service life: Because silica can improve the wear resistance and anti-aging properties of silicone leather, it can extend the service life of silicone leather. In the process of long-term use, silicone leather is not easy to damage, cracking and other phenomena, to maintain a good use effect.

3. Introduction of All Types of Substrates (Material, Manufacturing Process, Characteristics and Application)

All kinds of substrates attached to silicone skin mainly include polyester, microfiber, cotton and linen materials, Lycra, Pique, micro suede, stretchy fabric, Knitted fabric, non-woven fabric, flannelette, PET, PC, TPU, PI FILM 3M adhesive tape etc.

Yacht

- Silicone leather layer fabric used: microfiber, back coating, cow fiber, imitation cashmere, two-sided stretch

- Pattern used: Grain pattern, cross pattern, litchi pattern

Home Sofa

- Silicone leather layer fabric base used: cow fiber, imitation cashmere, back coating, microfiber, PK cloth

- Pattern used: Lychee pattern, cow pattern, Nappa pattern

Headphone Cover (Rounded Corner or Special-Shaped Cover)

- Silicone leather layer fabric base: four-sided stretch

- Pattern used: Lychee pattern, DE-43 pattern

Luggage

- Silicone leather layer fabric base: microfiber, PK cloth, back coating, two-sided stretch

- Pattern used: Sheep pattern, cow pattern, crocodile pattern, snake pattern, cross Pattern used, geometric pattern

Medical Bed

- Silicone leather layer fabric base: PK cloth, two-sided stretch

- Pattern used: Nappa pattern

Medical Clothing

- Silicone leather layer fabric base: two-sided stretch

- Pattern used: Plain weave

Shoe Materials

- Silicone leather layer fabric base: microfiber, back coating

- Pattern used: Lychee pattern, cow pattern, tumble pattern

Gloves

- Silicone leather layer fabric base: suede, beautiful velvet, microfiber

- Pattern used: Needle pattern, small pattern, cow pattern, lychee pattern

Swimming Cap/Swimming Trunks

- Silicone leather layer fabric base: two-sided elastic

- Pattern used: Tong weave

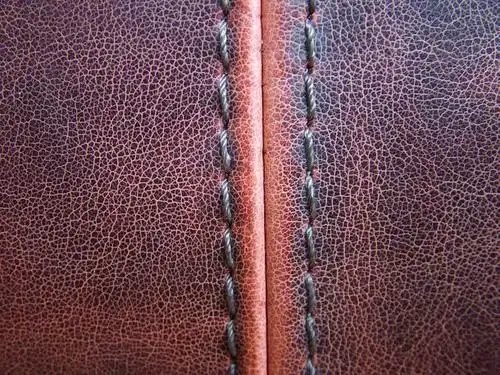

Car Seat

- Silicone leather layer fabric base: microfiber

- Pattern used: Cow pattern, lychee pattern

Car Covering

- Silicone leather layer fabric base: microfiber, PK cloth

- Pattern used: Gravel pattern, cow pattern, lychee pattern

Car Mats

- Silicone leather layer fabric base: microfiber, back coating

- Pattern used: Tumble pattern

Balls

- Silicone leather layer fabric base: microfiber

- Pattern used: Ball pattern

Belts

- Silicone leather layer fabric base: microfiber, back coating

- Pattern used: Cow pattern, lychee pattern

Clothing/Pillow/Leisure Sofa

- Silicone leather layer fabric base: air layer, health cloth, suede

- Pattern used: Sheep pattern, crocodile pattern, lychee pattern

3C Electronics

- Silicone leather layer fabric base: PET, PC, TPU, glass fiber, two-sided elastic

- Pattern used: DE-43 pattern, lychee pattern, geometric pattern, optical 3D, DE-43 pattern

Plate Decoration

- Silicone leather layer fabric base: PET

- Pattern used: Lychee pattern, silk pattern

Z.S.R Silicone coated fabrics are for use as a textile in the manufacture of furniture upholstery, furnishings, trim, decorative features.

Contact Z.S.R to custom your own silicone leather layer fabric base and pattern or texture to fit your projects.

Polyester Backing

Polyester backcloth Polyester backcloth is a fabric made of polyester fiber as a raw material, with high strength and wear resistance, suitable for applications that need to withstand greater friction. It also has good wrinkle resistance and shape preservation, easy to clean and not easy to pilling, suitable for making sofas, car seats and other items that need to maintain shape for a long time.

Microfiber Backing Cloth

Microfiber cloth is a kind of fabric that does not require spinning and weaving. It is composed of fibers with very small fineness of monofilament. It has high elasticity and good breathability. This backing cloth is often used to make high-end household items, such as sofas, bedding, etc., to provide a comfortable touch and durability.

Cotton Linen

Cotton and linen cloth is the component of cotton containing linen, also known as cotton and linen interwoven fabric. The cotton and linen cloth is dyed with various colors and has rich colors. Because the fabric is relatively thick, no irritation to the skin, and jute fiber unique high absorption and moisture characteristics, the fabric is particularly suitable for labor protective clothing material, can replace denim, but the price is much lower than denim.

4. The Advantage of This Composition of Silicone Skin

Silicone leather is a kind of polymer material, which has many advantages. The following are the main advantages of silicone leather:

- Thermostability: The maximum use temperature of silicone leather can reach 220 °C, and the short-term use temperature can be as high as 300 °C, so it is suitable for a variety of occasions requiring high temperature resistance, such as electrical appliances, electronics, automotive, aviation and other fields.

- Waterproof and dustproof anti-fouling: Silicone skin has good waterproof and dustproof performance, which can protect the internal components from the external environment; Excellent surface performance, with good anti-fouling characteristics.

- Fire resistance: It can slow down or stop the spread of flames when encountering fire sources, improving the safety of materials.

- Weather ability: Silicone leather has excellent weather resistance and can adapt to various climatic conditions.

- Good softness: Silicone leather has good softness and good elasticity, so it is suitable for products that need bending, stretching and other deformation.

- Health and environmental protection: Silicone leather does not contain harmful substances to the human body, is a safe and environmentally friendly material.

5. When Do I Use Silicone Leather with Different Ingredients

Silicone leather according to the different composition, can be mainly divided into full silicone leather and semi-silicone leather.

Full Silicone Leather

All silicone leather is made of 100% silicone material. Due to its full use of silicone material, all-silicone leather has the following characteristics:

- Superior performance: All-silicone leather has better softness, elasticity and durability, while also being more waterproof.

- Simple processing technology: Because all the silicone materials are used, the processing technology is relatively simple, and there is no need to consider the mixing of different materials.

- Long service life: Full silicone because the leather surface is full silicon, so under normal use, the service life of full silicone leather can reach 5-10 years.

- Wide application: Due to its superior performance and wide applicability, all silicone leather is widely used in electronic products, furniture, automotive interior and other fields.

Semi-Silicone Leather

Semi-silicone leather is made from a mixture of silicone and other materials. Its features include:

- Performance differences: The performance of semi-silicone leather depends on the ratio and mixing of silicone and other materials, and may not be superior to all-silicone leather. Complex processing technology: more processing technology and technical requirements are needed to achieve the mixing and combination of different materials.

- Short service life: Because only part of the surface layer is made of silicone material, after a long time of use, there may be problems with the silicone layer falling off, and some even have quality problems within half a year.

- Specific applications: Mainly used in areas that need to combine a variety of materials, such as some special shoe materials, bags and so on.

In general, full silicone leather and semi-silicone leather have their own characteristics and advantages, which material to choose depends on the specific application needs and scenarios. In the future development, with the continuous progress of science and technology and the diversification of application needs, the application field of silicone leather will be more extensive and in-depth.

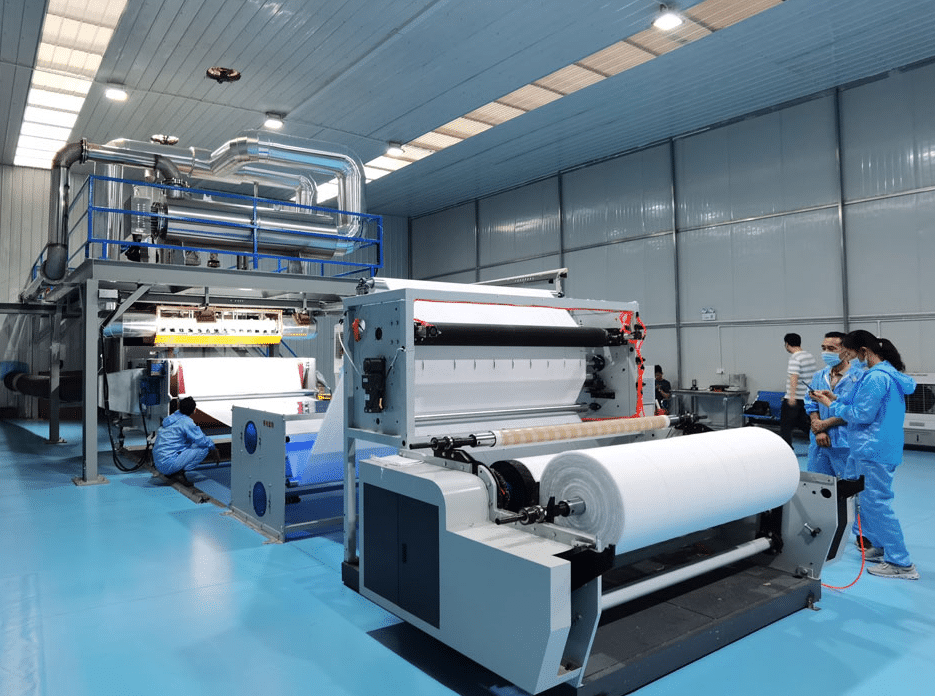

Z.S.R aims to provide the designers with more flexibility in design and respond to customers’ requirements by offering a wide range of customized options, including color, fabric base layer and surface textures silicone leather. What’s more, we support the roll-to-roll (R2R) process. The lamination of our Silicone Vegan Leather with other textiles is easily achieved by using existing R2R processes without changing the current production lines or supply chain.

ZSR Group Also offer the Custom silicone leather service with the custom silicone leather Base fabric layer, color, texture, application, sizes, logo, custom printing, custom silicone leather pattern, brand, package to the leather wholesalers for them to serve the local baby, Pets, Furniture, Vehicles, Healthcare, Sports, 3C Electronic, Upholstery Manufacturers industry.

6. Where Would You Use Different Components of Silicone Leather

Because silicone leather has many advantages, it has been widely used in various fields. The following are the main application areas of silicone leather:

Electronic appliances: Silicone leather can provide good touch and durability, suitable for a variety of electronic and electrical products manufacturing, such as mobile phones, iPad, computers protective case and so on.

Car interior: As the silicone leather’s wear-resistant and easy to clean characteristics, silicone leather is suitable for automotive manufacturing, such as automotive rubber seals, automotive wire covers, steering wheel covers, seat covers and other products.

Food and drink: Silicone leather is suitable for food and beverage fields, such as food packaging, beverage bottle package, etc.

Medical equipment: Silicone leather environmental protection and aging resistance characteristics make it have a certain market in medical equipment, and it is suitable for some medical device manufacturing, such as medical bedding, cushion, back pad and so on.

A construction Upholstery project: Silicone leather is suitable for construction engineering, such as waterproof materials, sealing materials and so on. Z.S.R is the leading supplier of high-performance faux leather to the hospitality, healthcare, contract, education, and general upholstery markets. We work with the Architects, Commercial and Office Fabric Selection Designers, Fabric Specialist, Material Consultant, Material Specialists together designs and make the custom silicone skin in an assortment of durability and Stain resistance to empowering their project’s success.

Furniture decoration products: Silicone leather is widely used in furniture decoration products, such as leather sofas, seats, decorations, etc., because of its soft, flexible and has the feel of leather and is welcomed. Z.S.R. team work with the Furniture manufacturers’ product development manager, Fabric Selection Designers, product manager, Product Developers, R&D Engineers together designs and make the custom silicone skin to empowering their Furniture product’s success.

7. How to Choose Silicone Leather According to Application

Daily Leather Goods

- Appearance texture: If the production of wallets, handbags and other portable small leather goods, preferred texture, soft luster silicone leather, touch skin.

- Lightness: This kind of leather goods often need to be portable, silicone leather should be light enough, too heavy will increase the burden of carrying.

- Bending resistance: Daily frequent opening and closing, bending, the material should be bending resistance without deformation, no cracking, after multiple bending tests without obvious creases is preferable.

Home Decoration

- Fire performance: Used for sofa, throw pillow, to check the fire rating of silicone leather, home fire scene, has good flame retardant, can reduce fire hazards.

- Dirt resistant and easy to clean: Living room, bedroom easy to stain, choose smooth surface, anti-fouling coating, wipe with a wet cloth that is clean, easy to take care of.

Automotive Upholstery

- Temperature resistance: When the car is parked, the temperature difference is large, the summer high temperature exposure, the winter cold, the silicone leather should be able to withstand the changing temperature range.

- Wear resistance: The seat and steering wheel cover often rub with the human body and clothing, and it is necessary to select high-wear-resistant silicone leather, which can be durable.

- Low odor: In the closed compartment, if the leather odor greatly affects the driving experience, it is necessary to choose environmentally friendly and odorless silicone leather, which meets the environmental protection standards of the car interior.

Z.S.R team work with the automotive product development manager, product designer, and product manager together to design and make the custom silicone skin to fit their product’s needs.

Silicone Fabric Coating And Curing

8. How to Choose the Backing Cloth According to the Application (Home Decor, Automotive Interior, Fashion Accessories)

When choosing a substrate for home decoration, the following key factors need to be considered: material, style adaptation, use scenario and environmental performance.

Material Selection

Non-woven wall fabric: The use of natural fibers such as cotton, hemp or polyester, acrylic and other synthetic fibers, through non-woven molding, resin, printed color pattern. Non-woven fabric bright color, smooth surface, elastic, not easy to age, no irritation to the skin, has a certain permeability and moisture resistance, can be scrubbed not fade.

Paper rattan wall cloth: Paper rattan is a relatively new imported decorative material, its soil yellow and rattan color is the same, strong toughness, easy construction.

Natural fiber woven wall cloth: made of natural fiber woven, with rustic characteristics, mainly grass woven wall cloth, hemp woven wall cloth and cotton fabric. Grass fabric wall cloth and cotton fabric wall cloth for dyeing treatment, the surface is soft and smooth; The texture of the hemp fabric wall is simple, and the surface is not dyed and shows the original appearance.

Acrylic yarn fiber wall cloth: Wall cloth made of acrylic yarn fiber, soft texture, thin thickness, a variety of colors and combinations, suitable for large walls or overall mass use.

Style Adaptation

Scandinavian style: Focus on natural and fresh, classic white and light cloth is favored, they are ethereal and pure, with green plants, log furniture, instantly create a relaxed and comfortable atmosphere. Embellishment color choose high saturation of solid colors, such as lemon yellow, mint green, etc., will make the whole space jump a lot.

Simple modern style: Modern style pursuit of fashion and trend, preference concise, beige white, light gray system of cloth is the universal choice. Beige white soft and warm, can brighten the space, give home warm feeling; Light gray calm and elegant, suitable for all kinds of simple furniture, highlighting the low-key texture.

Classical Chinese style: Pay attention to calm atmosphere, black, white, gray, brown and other light colors are common background colors in the new Chinese style. These tones can not only set off the darker Chinese furniture, form a hedge of color, but also enhance the visual effect, making the whole space more harmonious and comfortable.

Usage Scenario

- Bedroom: Pay attention to comfortable skin, pure cotton knitted fabric soft skin, spread on the bed, warm touch, help to improve the quality of sleep; If there is noise, you can also choose a curtain with a soundproof interlayer.

- Living room: Large flow of people, the bottom cloth to wearable. Blend material combines the advantages of multiple fibers, wrinkle resistant and durable.

- Kitchen (bathroom): Water is more, waterproof and mildew is the key, PVC coated non-woven fabric, waterproof Oxford cloth for kitchen oil, sanitary interval water vapor, dirty wet cloth wipe that is clean.

- Environmental performance: Cloths in close contact with the human body, such as bedding and cushions, are preferred to have the best natural materials with environmental certification labels to ensure a safe and non-toxic living environment.

When selecting the base cloth for automotive interior, it is necessary to consider factors such as material, color and functionality.

Material Selection

- Pure cotton: Strong air permeability, soft touch, can improve the comfort of the carriage. However, its durability is poor and it is difficult to clean with stains.

- Polyester fiber: Durable dirt resistance, high color durability, but poor air permeability.

- Artificial leather: Waterproof and easy to clean, the appearance is close to leather, but the texture and durability are not as good as leather.

Color

- Solid color: The common interior color of the car is black, beige, brown, coffee and so on.

- Color matching: Through the combination of dark and light matching and color contrast, it can add vitality to the decoration.

Functionality

- Fire protection: The interior decoration should have fire protection performance to reduce the danger of emergencies.

- Waterproof: Some parts of the car are easy to contact water and stains, waterproof cloth can avoid penetration.

- Non-slip: The items placed on the seat cover and the foot pad cannot slide easily, and the non-slip bottom cloth can ensure driving safety.

Fashion Accessories

When choosing the base cloth for fashion accessories, you need to consider the material, color style and functionality.

Material Selection

- Leather: Strong, durable, tough and fine, the backing cloth is suitable for belt accessories. After tanning and dyeing, it can present a variety of styles such as retro and modern, and can be wiped and maintained daily.

- Cotton: Skin-friendly breathable, moisture-absorbent warm. Cotton cloth is often used in embroidery base cloth, because of its soft texture, can well show the details and beauty of embroidery, also often used as a handkerchief, head band base cloth, sweat absorption and comfort.

- Polyester: Polyester material light and elegant, suitable for making a variety of light, elegant accessories, such as cape, gauze scarf.

Color Style

- New Chinese style: A combination of traditional and modern elements, often used in new Chinese style decoration. The base cloth is made of traditional Chinese color or popular color and high density polyester fiber bright silk, and the pattern is sewn on the base cloth to appear more three-dimensional.

- Floral: Filled with pastoral and girlish feeling, light color small floral suitable for spring theme handkerchief, hairpin, lively and sweet; Large and gorgeous floral more retro style, suitable for holiday wind straw hats, straw bags.

- Modern abstract: Full of modern art, irregular lines, geometric color blocks, can make scarves, ties and other accessories become modeling highlights.

Functionality

- Elastic demand: Accessories such as hair rope and garter should be made with elastic base cloth. Spandex blended cotton cloth and elastic lace can expand and expand with body movements, making them comfortable and firm to wear.

- Shaping needs: To make three-dimensional jewelry, it is necessary to use a stiffer base cloth, such as lined thick silk and cardboard composite cotton cloth, which is convenient to shape and maintain the shape for a long time.

More About silicone leather

Conclusion

Silicone leather is an environmentally friendly and durable artificial leather. The components of silica gel mainly include silicone polymers, fillers and crosslinkers. Z.S.R Silicone leather fabrics are inherently resistant to anti-fouling, anti-allergic, environmentally friendly, odorless, flame retardant, highly abrasion-resistant, skin-friendly, excellent durability and temperature, UV, weather, and hydrolysis resistance. With low VOC emissions. They work together to form the characteristics of silicone leather.

Z.S.R work with the different industry product fabric selection designers, product developer, R&D engineer, product manager together designs and make the Silicone leather fabric in an assortment of tear strength, hydrolysis resistance, waterproof and stain resistant, Wear resistant and scratch resistant, Heat/Cold temperature resistance, base layer, colors and texture to empower automotive interior, furniture, luggage and other industry product’s project success in design and functional requirements.

Contact Z.S.R to custom the composition of silicone leather to fit your projects.

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.