Can Silicone be welded or cut

1. What is silicone

Silica gel is a kind of highly active adsorption material, which belongs to amorphous substance and is a porous substance with different particle sizes formed by proper dehydration of silica gel. It has an open porous structure, can adsorb many substances, and is a good desiccant, adsorbent and catalyst carrier. Silica gel, as an important amorphous material, its core composition is silicon dioxide (SiO2), which accounts for the vast majority of the total mass of silica gel, more than 98%. In addition to the main silica, it may also contain trace amounts of aluminum, sodium, iron and other elements, but the total amount of these impurities does not exceed 2%.

Ordinary silica gel: Also known as non-oxygenated silica gel, it has good precipitation, hydrophilicity and softness, and is often used in the manufacture of seals, electronic components and thermal insulation materials .

Dimethyl silica gel: This is one of the earliest types of silica gel to be put into economic activity. It can maintain good elasticity in the range of -60 ~ 200℃, and has excellent aging resistance, electrical insulation performance, moisture resistance, shock resistance and other characteristics. Dimethyl silica gel is mainly used for fabric coating, and can also be made into various extrusion and calendering products, which are used in mechanical and electrical, aviation, transportation and medical industries.

Methyl vinyl silicone: This is currently the most versatile kind of silica gel, which dominates the production of silica gel. The vulcanization performance of methyl vinyl silica gel is greatly improved by introducing a small amount of vinyl into the macromolecular structure of silica gel. It has a wide operating temperature range, easy vulcanization, small compression deformation, solvent expansion resistance and high pressure steam stability, but also has excellent cold resistance.

Methyl phenyl vinyl silicone: This silica gel introduces a methyl phenyl siloxane link or diphenyl siloxane link into the molecular chain of methyl vinyl silicone. In addition to all the advantages of methyl vinyl silicone, it also has excellent low temperature resistance, ablation resistance and radiation resistance.

fluorosilicone: With excellent oil resistance, high temperature resistance and chemical corrosion resistance, suitable for aviation, aerospace, petrochemical and other high-tech fields.

Sulfurized silica gel: With vulcanizing agent as catalyst, it has excellent elasticity, oil resistance, heat resistance and chemical resistance, and is often used in the manufacture of rubber products and seals.

liquid silicone rubber: At room temperature as a fluid state, can be heated to become an elastomer, with excellent sealing and insulation properties, suitable for electronics, optoelectronics, communications, automotive and other fields.

2. Why can silicone be cut

Silica gel has a variety of physical properties, including adsorption, hardness, tensile strength and tearing strength . The characteristics of silica gel will have a certain impact on cutting:

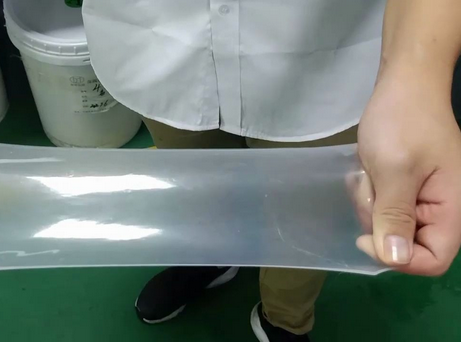

Silica gel has a certain viscosity at room temperature because of its high flexibility and high viscosity, but when it is cut, its cutting surface is flat and it is not easy to produce burrs. When the silica gel is subjected to external force, it can undergo a certain degree of deformation, which makes the silica gel can be cut into various shapes.

At the same time, the cutting surface of silica gel is smooth and not easy to produce burrs, which is one of the important reasons why silica gel is applied in many fields. In addition, silicone products with different hardness will affect their extrusion strength, accuracy and tear resistance during the cutting process, which will affect the stability and accuracy of cutting .

3. How can silicone be cut

I: Mechanical cutting

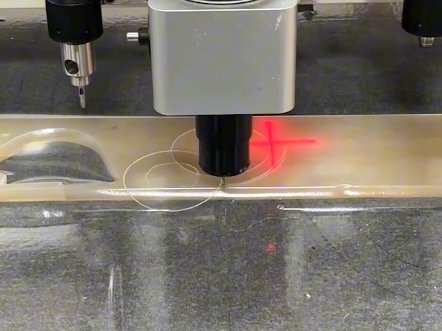

If the silica gel thickness is large or requires higher accuracy, manual cutting is difficult to meet the requirements, mechanical cutting can be used: Choose the right mechanical cutting equipment, such as laser cutting machine, CNC cutting machine, etc. Place the silicone sheet on the cutting machine and set it according to the cutting requirements; Open the cutting machine, cut, and clean up after cutting.

Mechanical cutting can achieve high cutting accuracy, the error can be controlled in the micron level, can maximize the use of raw materials, reduce production costs and material waste , but also significantly improve the cutting speed, shorten the production cycle, so as to improve production efficiency .

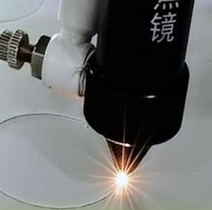

II: Laser cutting

Before cutting, it is necessary to clarify the cutting depth and cutting speed of silicone. The cutting depth should not be too deep to avoid silica gel burning or leaving traces; The cutting speed should be moderate, too fast may lead to scars or cracks on the silicone surface, too slow increases the risk of deformation, and the stability and accuracy of the laser cutting machine should be ensured when cutting. Monitor the cutting process and adjust parameters in time to deal with possible cutting problems.

Usually, the use of fiber lasers for cutting, because of its higher cutting accuracy and stability, can better meet the needs of silicone cutting.

III: Water jet cutting

The use of high pressure water flow and abrasive, can quickly and accurately cut various shapes of silicone products, and does not produce heat affected zone and cutting gas, non-destructive cutting of silicone products. However, the cost of water knife cutting equipment is high, and professional operators are required, which is not suitable for larger size silicone products.

IV: manual cutting

Prepare the silicone sheet and the cutting tool. Use a pencil or thin pencil to outline the shape or size to be cut on the silicone sheet to ensure the accuracy of cutting. Then use the cutting tool to start cutting according to the lines outlined. After cutting, sand the incision with sandpaper and polisher to smooth the silicone surface and remove burrs or irregularity generated during cutting.

The operation of manual cutting is simple and low cost, especially suitable for small batch production and precision requirements are not high.

4. Why can silicone be welded

The molecular structure of silica gel determines the particularity of its surface properties. The surface of silica gel is often porous, high specific surface area and a large number of active functional groups. Because the chain and ring structures in the molecular structure of silica gel are intertwined, a complex microstructure is formed. These microscopic structures make the silica gel surface have many active sites and surface adsorption capacity, as well as good flexibility, chemical stability and high temperature resistance.

5. How can silicone be welded

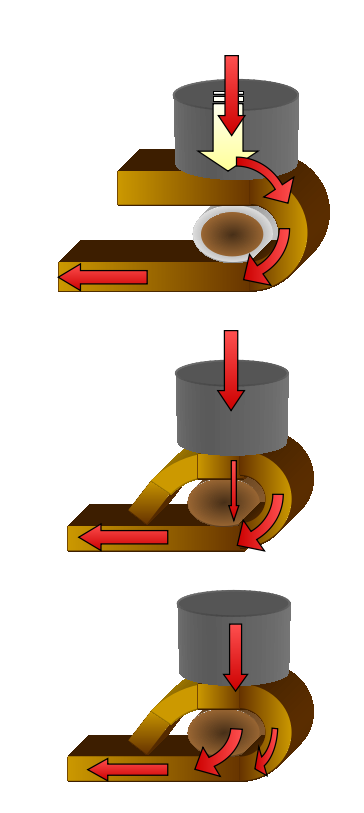

The commonly used silicone bonding methods are hot pressure welding, silicone plate self-bonding welding and chemical reaction welding.

I: Hot pressure welding method

The silicone plate is welded together with another piece of silicone plate, metal plate, glass and other high-temperature heat-resistant materials using a hot press. This method is simple to operate, but requires a professional hot press and related technical personnel.

II: Silicone plate self bonding welding method

After melting the silicone sheet itself, it is pressed to the part that needs to be connected, and the connection is realized by self-bonding. This method is relatively simple, but it requires attention to control the heat and operation skills.

III: Chemical reaction welding:

The silicone plate is connected with another material after a chemical reaction. This method requires the use of specific chemicals, and the operation requirements are high, it is recommended that professional manufacturers complete.

Learn More About Silicone Molding Method And Process

6. What should we pay attention to when operating

Safety: When performing welding and cutting operations, it is essential to wear appropriate personal protective equipment, such as safety helmets, protective glasses, gloves, etc., to prevent open flames and metal splashes and reduce eye damage.

Workplace safety: Protect those around you from harm during welding and cutting, and ensure that the workplace is protected from threats such as fire. Remove flammable or explosive materials from the surrounding area to ensure that flames and smoke do not endanger nearby people.

Knowledge : Welding and cutting are risky operations that require an understanding of metal construction, all aspects of welding and cutting technology, and the characteristics of machines and equipment. Awareness of safety and health can be increased through training courses and licensing examinations .

Equipment selection: When selecting the tools and machines required for welding and cutting, it is necessary to thoroughly understand the performance of the equipment, check whether all controls are working properly before use, and carry out necessary maintenance and inspection .

conclusion

In short, silicone can be welded and cut, and there are a variety of welding and cutting methods, when operating, you need to pay attention to your own safety and workplace safety; Master relevant knowledge in advance to enhance the awareness of safe operation; When selecting the tools and machines required for welding and cutting, the performance of the equipment should be thoroughly understood, maintained and checked.

ZSR Group has rich experience in producing Custom silicone products with FDA or LFGB Approved standard.We have the FDA register list number is 3011147430.

Any Silicone products or Silicone project need technical support, you also can custom Silicone products at ZSR Group.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.