Silicone Product Prototype Guide: Manufacturing, Selection, and Costs

Every decision made during the prototyping phase impacts the yield and reputation of mass production. Getting the first prototype right sets the tone for future reputation and yield, below are five key considerations:

- Material selection (LSR/HTV),

- Mold design (wall thickness/parting/venting),

- Process window (mold temperature/venting/curing/disulfide),

- Appearance and feel (texture/coating/parting line),

- Compliance and odor (migration/total volatiles/disulfide)

Any failure in any link may eventually manifest as “visible” defects – flash, odor, dust adhesion, color difference, assembly interference.

This article draws on our engineers’ 26 years of experience in prototyping and mass production in the silicone industry. It also incorporates publicly available online resources, customer reviews, and key points from standard specifications to systematically explain how to create silicone product prototypes, how to control them, and how to save money for create silicone products.

If you are a brand/product manager, structural/process engineer, procurement and supply chain personnel, quality/compliance personnel, marketing and channel partners seeking a comprehensive understanding of silicone product prototyping, please read the details below:

What is a silicone product prototype?

A silicone product prototype is a physical or digital model used during product development to verify design feasibility. Its materials, components, and assembly methods must be consistent with the final product. Before mass production, a functional prototype is created using near-final materials and processes (such as LSR injection molding, solid silicone compression/transfer molding, and RTV room temperature vulcanization). It is used to verify appearance, feel, dimensions, fit, temperature resistance, odor, and regulatory compliance. Core functions include low-cost testing, team communication, and user feedback collection.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

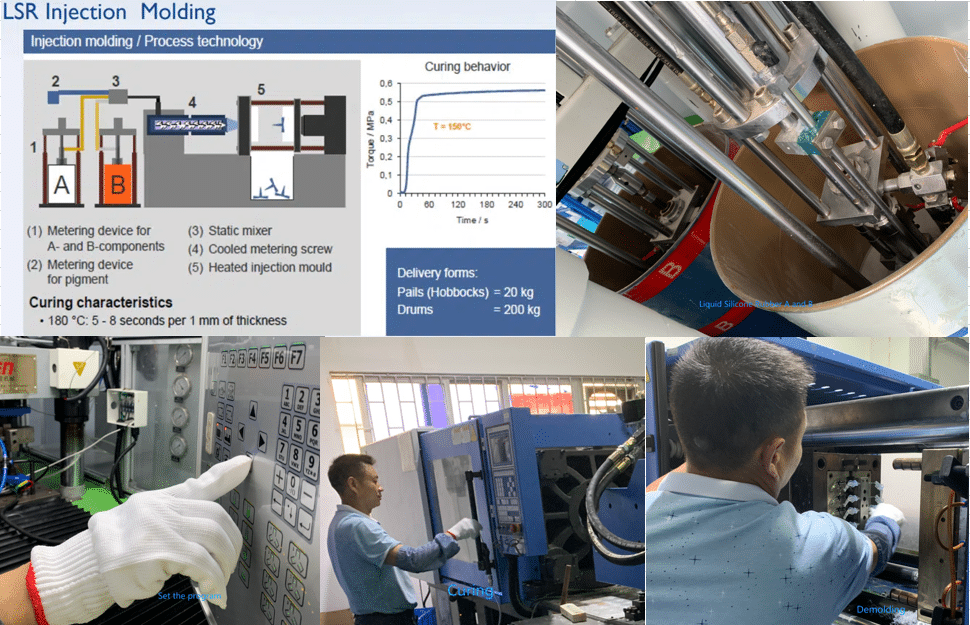

Liquid Silicone Rubber (LSR) Injection Molding

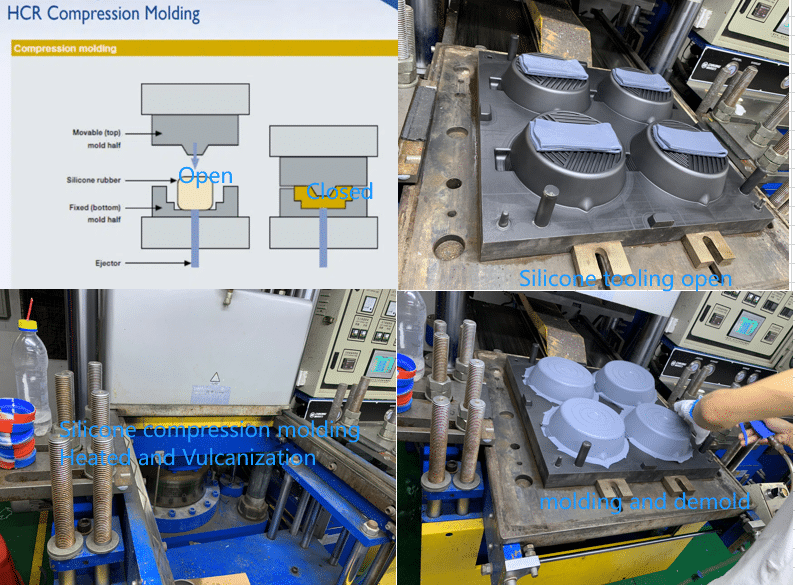

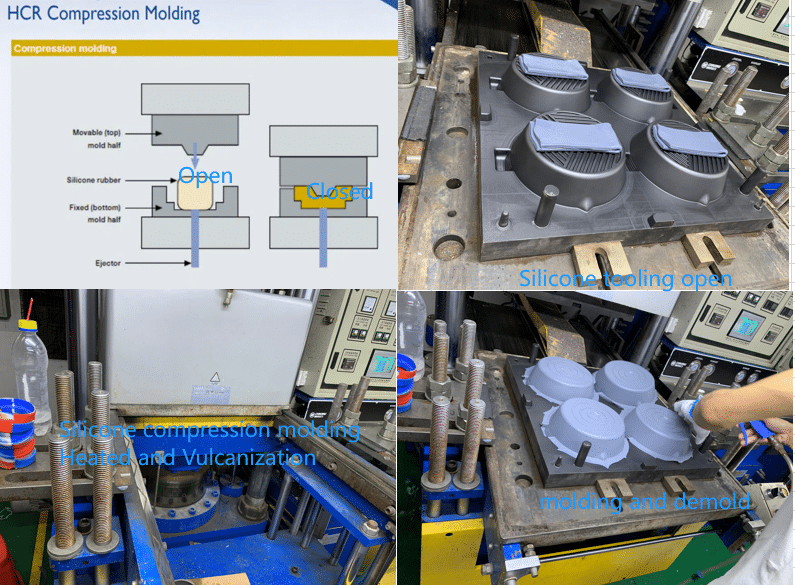

Silicone Compression Molding

Why create silicone prototype?

- Verify feasibility.

- Prototypes can visually demonstrate product form, functionality, and interaction logic, helping teams quickly verify design rationality.

- Reduce development risk.

- Prototypes can identify potential issues early (such as structural design flaws, material compatibility, and process risks). They can be tested and documented for shore hardness, tensile/tear strength, compression set, migration/total volatiles, odor, and aging. This helps avoid costly delays in later large-scale production.

- Promote cross-disciplinary collaboration.

- Prototype design can bridge the gap between designers and users and clients. Rapid prototyping validates concepts and ensures shared understanding of product goals. S1 functional samples can be used for initial testing of feel, assembly, temperature resistance, and odor.

- Samples can be used for third-party testing and endorsement:

- Evidence of ASTM/ISO physical properties, migration/total volatiles, dishwasher/high/low temperature cycling, and other tests can be generated, transforming them into selling points.

- Shorten time to market:

- Rapid prototyping combined with parallel testing can reduce project timelines by 30–50%.

Are you looking for a silicone products prototype manufacturer? Please contact us today to get your design quote. From 3D CAD modeling to prototyping to Mass Silicone production molding, we will help you along the way!

When will you need create the silicone prototype?

After concept freeze and before mass production mold launch; or when modifying an existing product (reducing odor/improving stain resistance/changing structure).

Project Kickoff (0–3 days)

Define application/regulatory region → Select materials (LSR/HTV/RTV) and hardness → Color scheme → Design for Material (DFM) review (parting/venting/texture/critical dimensions).

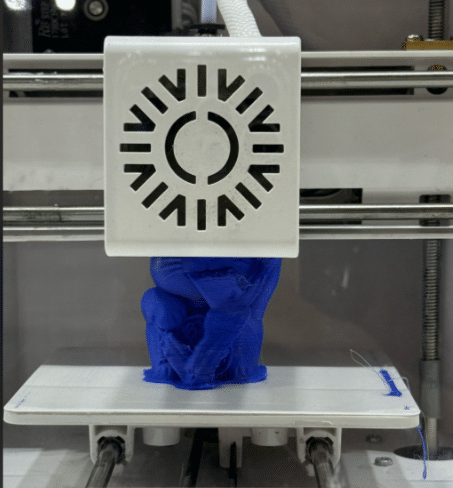

S0 Concept Sample (3–7 days)

Output: 3D print or RTV sample to verify appearance/feel and basic structure.

Tasks: Determine material routing, hardness, and color; conduct preliminary Design for Material (DFM) review (parting/venting/texture/tolerances).

3D print silicone products prototype

3D print silicone products prototype

S1 Functional Sample (7–15 days)

Process: Rapid aluminum compression molding or LSR small-cavity injection molding.

Tasks: Verify cure window, optimize flash and shrinkage, perform post-vulcanization odor removal, and complete preliminary appearance/dimensional/feel review.

S2 Engineering Samples (10–20 days)

Process: Mold temperature, venting, and number of cavities close to mass production; implement fixtures and perform SPC.

Tasks: Key verification of physical properties, total volatiles (TVE), migration, dishwasher/heat resistance, and UV resistance; assembly/tolerance chain locking; color matching freeze.

PV Small-Batch Trial Production (7–14 days)

Quantity: 200–1000 pieces

Tasks: Cycle time/yield/deburring/packaging verification; output PFMEA, control plan, FAI, and shipping inspection specifications.

200–1000 pieces; optimize cycle time and deburring solutions → produce PV samples and test packages → review and freeze mass production parameters.

Z.S.R consists of a strong engineering design team 12 experts with more than 20 years’ experience. We offer personalized services and supports for projects through all steps of products development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly. Just offer your ideas or drawing to Z.S.R‘s expert, You can get full plan for your silicone products project.

Where can you create silicone product prototype?

Guangdong, Zhejiang, and Jiangsu, especially Shenzhen, Guangzhou, and Dongguan in Guangdong, all have professional organizations offering silicone product prototyping services, including one-stop silicone product production services. Dongguan’s silicone product manufacturers, in particular, offer comprehensive services from product design to mold development.

Jution Silicone Rubber Products Co., Ltd. specializes in the R&D, design, customization, production, and sales of silicone products.

Dongguan Baishun Silicone Plastic Products Co., Ltd. manufactures silicone and PVC figurines, supporting customization in a variety of materials.

Dongguan Zhisheng Gift Co., Ltd. specializes in 3D cartoon figurines and epoxy crafts, and is FDA-certified.

Dongguan Detai Rubber and Plastic Products Co., Ltd. provides first-run and mass-produced anime-related products, including trendy figurines and blind box figurines.

These factories can produce the prototype of the silicone products you need through compression/transfer molding, LSR injection, secondary vulcanization, automated encapsulation, and glue dripping production processes.

Z.S.R is a full-service custom silicone products manufacturer offering end-to-end customization, from mold development, prototyping to mass production and packaging. Z.S.R already customized more than 13.500 silicone products prototype projects for our partner in the past 16 years with much experience in silicone products technical solution.

Contact Z.S.R to get your silicone products prototype solution.

How to Create silicone product prototype?

A. Requirements Clarification and DFM (Design for Manufacturability)

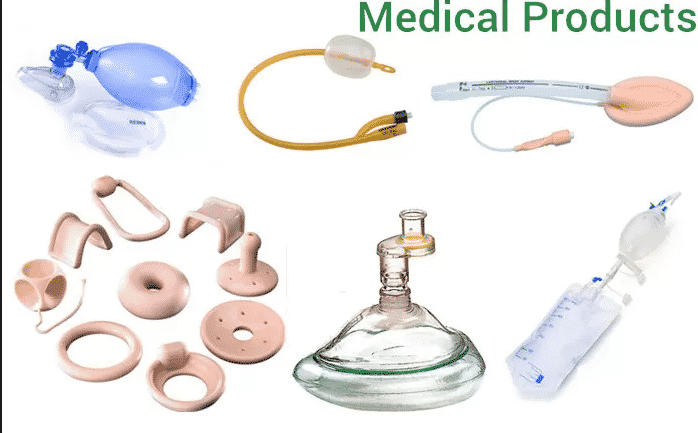

Application Scenario and Regulations: Is it food contact, maternal and infant, or medical? Temperature range? Contact media (water, oil, acid, alkali, or alcohol)?

Material Routing:LSR (liquid silicone rubber, platinum catalyzed): A/B ratio of 1:1; thin walls, complex flow paths, and high cleanliness requirements (maternal and infant/medical).

HTV/VMQ (solid silicone rubber, peroxide or platinum-based): medium-thick walls, cost-sensitive applications, and a wide range of colors.

RTV (room temperature vulcanized)/3D printing silicone: proof of concept, small batches, and soft structures.

Key Structural Features:Recommended wall thickness: ≥0.8–1.2 mm; avoid sudden changes in thickness; use ribs to prevent sudden changes in thickness; allow for draft angles; rounded corner transitions; draft angle ≥0.5–1°. Ensure proper parting, with the parting line avoiding critical exterior surfaces and venting grooves (0.005–0.02mm). Pre-determine the location of key surface textures and parting lines to allow for reduced flash.

Tolerance recommendation: Standard M2; critical fits should be closer to M1. 100% inspection of the jig is required.

B. Prototype Selection

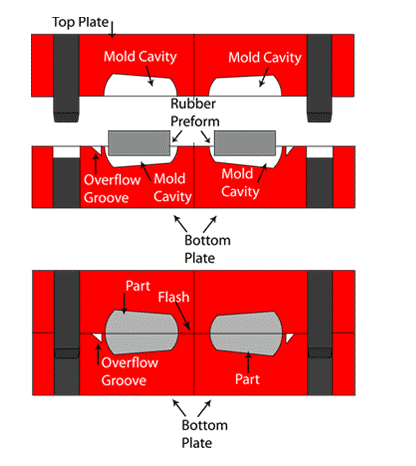

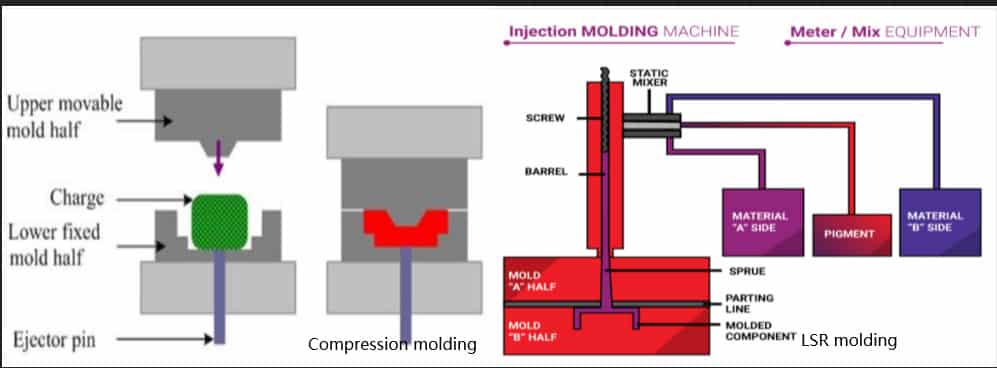

Solid Compression/Transfer Mold

Mold: Rapid aluminum mold or small steel mold; single-cavity/small multi-cavity.

Molding temperature: 160–180°C; molding time depends on thickness and system.

Advantages: Fast mold opening, low cost, and easy trial and error. Disadvantages: Lower consistency and automation than LSR injection molding.

LSR injection molding

- Equipment: Dedicated LSR injection molding machine with cold runner needle valve; Mold temperature 160–200°C; A/B metering error ≤±1%.

- Advantages: Clean, good thin-wall filling, high automation, and minimal flash. Disadvantages: High initial mold investment.

RTV/Pouring

Room temperature curing, suitable for very small batches or complex concepts; pay attention to degassing and post-baking for odor removal.

C. Formulation and Color

Hardness: Shore A 10–80, commonly A20/30/50; select based on feel and holding power.

Additives and Post-Cure: For food contact/low odor, a platinum system with post-cure at 200°C for 2–4 hours is recommended.

Color: Use food-contact-grade masterbatch; Pantone color matching, ΔE ≤ 1.0–1.5; light-colored parts require more control over total volatile emissions and surface cleanliness.

D. Molding and Post-Processing

Parameter Window: Mold temperature, cure time, and pressure are optimized through Design of Experiments (DoEs); record in SOP.

Deburring/Post-Processing: Manual/freeze deburring → Water rinsing/IPA wiping → Post-cure (if necessary) → Drying → Spot check of appearance/dimensional/physical properties/odor.

Surface and Handfeel: Sandblasted/Textured/Mirror/Leather; Optional Skin-Feel Coating (Note food contact restrictions and adhesion).

E. Testing and Compliance

Physical Properties: Hardness (ASTM D2240), Tensile (D412), Tear (D624), Compression Set (D395), Temperature Cycling Resistance.

Chemical and Hygiene: Total Volatile Emissions (TV), Odor Sensory/GC, General Migration/Specific Migration (according to FDA/LFGB protocols).

Durability and Reliability: Dishwasher 50–100 cycles, Boil/Steam, Oven 230°C for a short time, UV/Perspiration/Oil Resistance.

Documentation: Material CoA/CoC, Test Report, SDS, Traceable Batch Number.

F. Pilot Production and Mass Production Rollout

Pilot Production: 200–1000 pieces; Verify CTQ (Critical to Quality) and cycle time.

Process documentation: PFMEA, control plan, fixtures, and First Article Inventory (FAI).

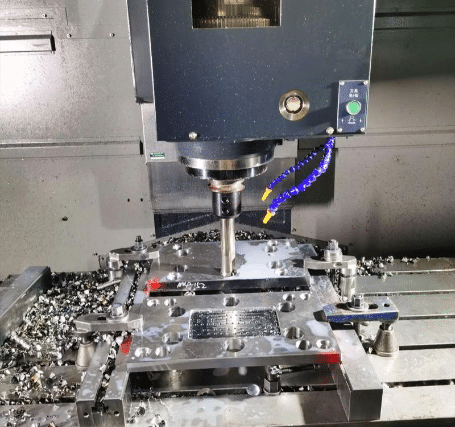

Production mold upgrade: Optimize cold runners, venting, and cavity count; introduce automated edge trimming and robotics; and lock in equivalent parameters.

Z.S.R have the capability for producing silicone tooling, producing HTV Silicone products, LSR molded silicone products, Molded multi-colored Silicone products. We also can Custom silicone tooling, Custom silicone molding, Custom Silicone compression molding, Custom LSR molding, Custom silicone Dripping injection dispensing (co-injection), Custom silicone fabric coating and curing molding. Z.S.R is a one-stop Custom molded silicone products manufacturer and silicone molding solution provider in the silicone products field founded in 2007.

Contact Z.S.R to create your own business line of silicone products from the prototype.

Custom Silicone Products | OEM/ODM Service

How much does it cost to create silicone product prototypes?

- Rapid compression mold (aluminum/Copper): $300–$1,200; Leadtime 7–12 days; $0.3–$3 per sample.

- Small steel compression mold (solid): $999–$4,000; Leadtime time 10–15 days; $0.5–$40 per piece.

- LSR injection mold: $2,000–$20,000; Leadtime time 2–6 weeks; $0.2–$50 per piece.

- RTV/casting/3D printing: $100–$500; Leadtime time 3–7 days; $1–$100 per piece.

- Testing and certification: Material report $200–$800; migration/total volatiles/aging package $800–$2,500; medical device services are charged separately.

The actual cost for creating silicone products prototype is affected by volume, number of cavities, texture, color, whether or not to use post-vulcanization, cleanliness requirements, and test scope.

How to choose the working process for silicone products?

LSR is recommended for thin-walled (<1 mm) delicate parts, complex flow paths, applications requiring extreme cleanliness and odor (infant and medical applications), and automated high-volume production.

Solid-state HTV is recommended for applications requiring medium-thick walls, rich colors, cost-sensitive materials, or large-area textures, simple structures, or no cleanroom required.

LSR silicone prototype mold

LSR silicone prototype mold

RTV/3D printing is recommended for proof of concept and rapid structural/tactile evaluation.

Z.S.R’s Silicone mold tooling ,Silicone Compression molding, Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot(LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations. All of silicone products manufacturing from silicone products development cycle under one roof- from designing products & building tooling to launching into full-blown production.

This creates a one-stop silicone solution to meet your scalability requirements for your Customized silicone products.

How to control the quality of silicone products?

With Z.S.R Unlimited customized silicone products service, Z.S.R custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality products for different industry application from industrial, residential, commercial to medical.

Z.S.R perform multiple rigorous tests throughout the silicone products manufacturing process to ensure that the quality of the silicone product meets expectations when it leaves the factory.

Contact Z.S.R to create your business of silicone products prototype.

How to clean silicone product prototypes and molds?

Sample cleaning (food/baby products):

For initial use, boil for 5–10 minutes or oven-dry at 100–120°C to remove odors. Daily cleaning: Use a neutral detergent in warm water, wipe with a soft cloth or sponge, and air dry. Avoid strong solvents and steel wool.

3C/industrial parts:

Gently wipe with deionized water or IPA to avoid damaging the tactile coating. If dust is present, use an air gun or dust removal roller.

Mold cleaning:

Use an air gun to remove daily burrs. Use a low-corrosive mold cleaner, cotton swabs, and a soft brush. Regularly clean carbon deposits in the vent slots. Use caution when using strong release agents (they can transfer oil stains and odors).

More FAQs

Summary

Getting the first prototype right sets the tone for future reputation and yield: material selection (LSR/HTV), mold design, accurate wall thickness and parting/venting, stable mold temperature/time/pressure and disulfide window processes, appearance and feel (texture/coating/parting line), and FDA/LFGB/REACH/10993 compliance and odor (migration/total volatiles/disulfide) compliance are five key factors.

Data speaks for itself: ASTM/ISO physical properties, migration and total volatiles, dishwasher and temperature cycle resistance, and ΔE color stability are all “replicable and endorsable” selling points.

Consider mass production from the prototype: Early involvement in tolerance levels, jigs, and quality documentation (FMEA/CP/PPAP thinking) will significantly smooth the transition to mass production. Equivalency lists, jigs and SPC, tolerance targets, FMEA, and control plans ensure a smooth transition from prototype to production.

Focused on user pain points: low odor, easy cleaning, dust resistance, temperature resistance, and color stability are common “buy switches” for kitchenware, maternity and baby products, consumer electronics, and industrial users.

If you already have a target market and dimensional sketch, Z.S.R. expert can directly convert it into a DFM review checklist, including material and process routing, S1/S2 milestones and test matrices, two-tier cost and delivery schedules, and a risk and countermeasures list. It also includes a recommended test matrix and packaging/labeling compliance templates, allowing you to have prototypes ready for testing within two weeks and trial production within six weeks.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.