Silicone Product Guide – Production Technology and Applications

What is silicone made of?

Silicone is made of highly active adsorption materials, the main components of which include silicon dioxide and other substances.

Silicone is an amorphous substance made by reacting sodium silicate with sulfuric acid and then undergoing a series of aging treatments. Its main chain structure is Si-O-Si, with silicon atoms connected by oxygen atoms and at least one organic group. This material is very soft and very stable and also has high flame retardancy.

There are many types of silicone material, please check the differences in silicone material to know more about that.

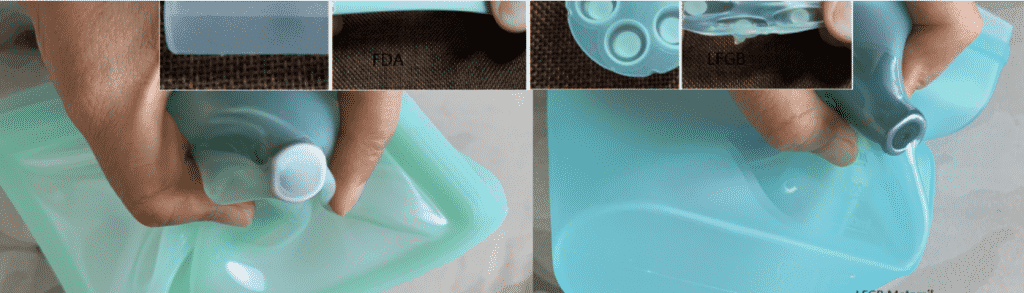

The Silicone Material Differences: LFGB food grade Silicone

What are silicone products?

Silicone products are products made from silicone as the main raw material. Silica gel is a porous substance made by properly dehydrating silicic acid gel. It has an open porous structure and can absorb a variety of substances. Therefore, it is widely used as a desiccant, adsorbent and catalyst carrier. Silicone products are safe, non-toxic, odorless, high and low-temperature resistant, easy to clean and have a long life.

How many moldings are processed for silicone products?

The Application of silicone products

Silicone products have a wide range of applications mainly due to their unique physical and chemical properties.

Silicone has high adsorption, good thermal stability and chemical stability, these characteristics make silicone products widely used in many industries:

Residential

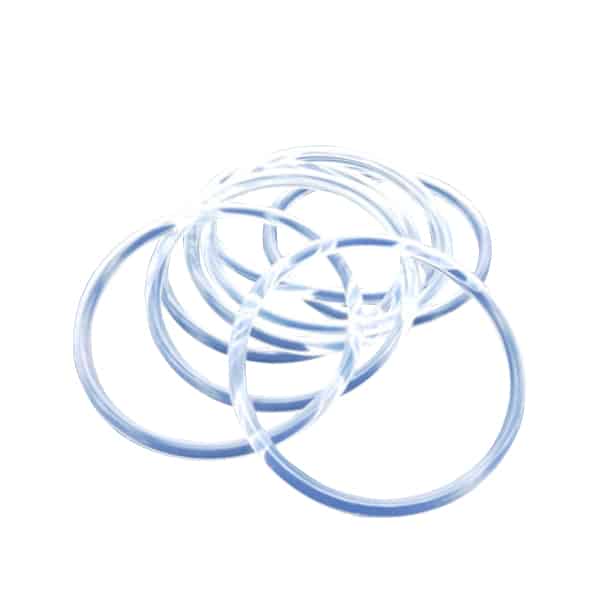

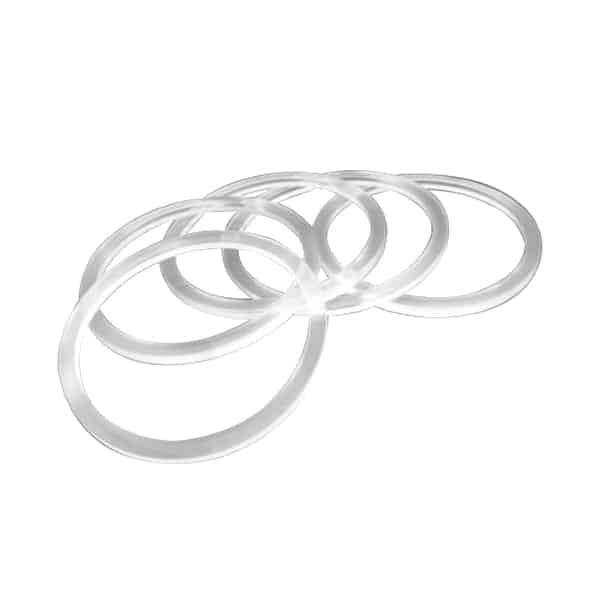

Daily necessities for home and houseware: Silicone products are widely used in daily necessities, such as silicone baking molds, silicone gloves, silicone sealing rings and other kitchen supplies, as well as silicone anti-slip mats, silicone bathroom mats, silicone door mats and other household items. These products not only improve the comfort and convenience of home life but also ensure the safety and hygiene of use.

Maternal and baby infant products: Silicone is also widely used in maternal and infant products, including silicone spoons, silicone bowls, silicone dinner plates, silicone teethers, silicone pacifiers, silicone baby food bottles, silicone bibs, etc. These products are deeply loved by parents and children for their safety, non-toxicity and fall resistance.

Outdoor products: Silicone products are also widely used in outdoor products, such as silicone water bottles, silicone backpacks, silicone sports shoe insoles, etc. These products provide great convenience for outdoor activities with their durability and comfort.

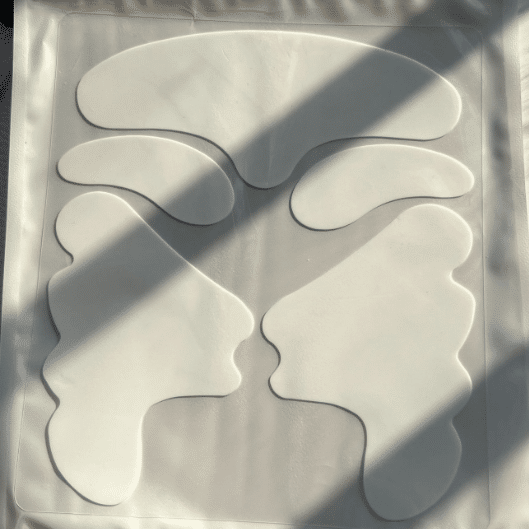

Beauty and personal care: In terms of beauty and personal care, silicone products such as silicone facial cleansing instruments and silicone facial cleansing puffs have become essential tools for skin care experts with their soft and easy-to-clean features, effectively cleaning the skin and keeping it fresh and smooth.

Medical products: The application of silicone products in the medical field demonstrates its combination of high technology and humanization, such as silicone catheters, silicone artificial organs, silicone medical dressings, etc., with their good biocompatibility, non-toxicity, and plasticity, providing patients with a safer and more comfortable treatment experience.

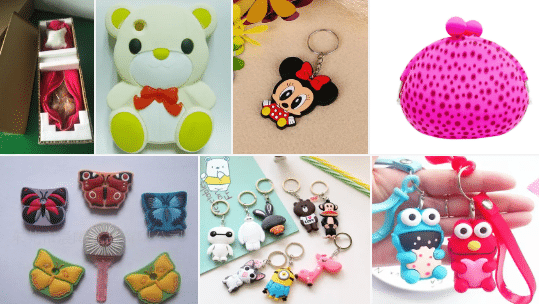

Toys and miscellaneous items: Silicone toys have become children’s favorite playmates with their safety, softness, and toughness. At the same time, miscellaneous items such as silicone anti-slip feet and transparent silicone pads have also brought more convenience and fun to daily life.

Electronic Protective covers: In consumer electronic products need silicone protective cases include protecting products from damage, improving user experience, and meeting personalized needs.

In summary, silicone products are widely used in the civilian field, from kitchen supplies to outdoor supplies, from maternal and child supplies to medical supplies, to toys and miscellaneous items, covering almost all aspects of daily life, providing great convenience and comfort for people’s lives.

Commercial

Promotional gifts:Z.S.R custom Logo silicone products, promotional silicone merchandise, gift giveaways, and logo silicone items that you’ll love. We offer logo branding services to the Promotional and License industries. We work with the promotional, Marketing and Advertising, Licensor, Licensee, wholesale, retail chain, gifts store, and product development companies together offer molded logo silicone products to the whole world to expand your brands and Market.

Hotels used for the trays, hanger tag, Commercial restaurants supply for the baking mold, baking mats

Industrial

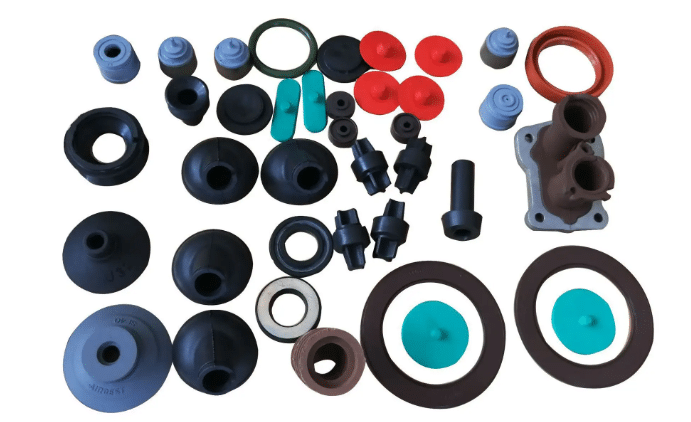

Silicone products are widely used in the industrial field, covering the electronics industry, medical devices, automobile manufacturing, aerospace and other fields.

Electronics & Electrical Industry: Silicone products are widely used in the electronics industry due to their excellent insulation and high-temperature resistance. For example, silicone products are used to make buttons, sealing rings, insulating sleeves and other parts to improve the durability and safety of the products. Silicone special treatment agents can further enhance the adhesion and stability of silicone products to ensure the safety and reliability of electronic components.

Medical devices: Silicone products are also widely used in the field of medical devices, such as artificial organs, catheters, implants and baby pacifiers. Silicone special treatment agents can improve the surface properties of silicone products, improve their antibacterial and corrosion resistance, and ensure the safety and effectiveness of medical devices.

Automobile manufacturing: Silicone products play an important role in automobile manufacturing, such as spark plug covers, battery connectors, mirror seals, etc. Silicone rubber products have unique heat resistance, cold resistance and electrical insulation properties, and have been well used in automobile engine systems, exhaust systems and fuel systems.

Aerospace: The application of silicone products in the aerospace field is also important. For example, silicone rubber products are used in gaskets, connectors, etc. They can withstand extreme temperatures and remain stable and durable under extreme environments and chemical stresses.

Food and Beverage Manufacturing Processing: Silicone is used to make various food molds, such as cake molds, fondant drawing molds, chocolate molds, candy molds, mousse molds, pudding molds, etc. These molds are usually made of food-grade silicone because they are non-toxic and odorless, harmless to the human body, and can ensure the safety and hygiene of food.

Silicone is used to make food-grade seals because it is safe, odorless, and will not contaminate food. These seals are used to ensure that food packaging is airtight and prevent food from coming into contact with air, thereby extending the shelf life of the food.

High-temperature process manufacturing: Sponge molding, building block molding, Geopolymer molding etc.

Lab table protective:Silicone products are mainly used in laboratories for transporting reagents, samples and solutions, as well as being a material with strong chemical resistance and stability, making them an ideal choice for laboratory operations protection. Such as protective sleeve for the bottle, protective mats for the table. Provides anti-skid, shock-absorbing, sealing and other functions to meet the design requirements of miniaturization and ultra-thinness of equipment.

Silicone products play an important role in laboratories due to their excellent physical and chemical properties. They are often used in laboratories, not only for transporting reagents, samples and solutions, but also for their chemical resistance and stability, making them an ideal choice for laboratory table operations protection.

These properties enable silicone products to maintain long-term stability and reliability in laboratory environments, thereby ensuring the accuracy and reliability of experimental results. In addition, the durability and easy cleaning of silicone products also make them one of the indispensable materials in laboratories.

Mass Transit: The application of silicone products in public transportation mainly includes silicone antibacterial hand pull rings, seals, sealing strips, silicone tubes, etc.

Hydraulics: The application of silicone products in hydraulic systems includes but is not limited to seals, oil seals, various flame-retardant silicone rubber parts, seals for pumps in hydraulic oil systems, diaphragms for sensitive components in regulators, heating plates for instruments, shock-resistant thorny rubber sheets, etc.

In addition, silicone rubber is also needed for wire sheathing, hydraulic systems, various seals, hoses, and hoses used in exposed systems on aircraft and aircraft. These applications demonstrate the important role of silicone products in hydraulic systems, including improving the sealing performance of the system, protecting the wires from damage, and ensuring the stable operation of the system.

Power Generation

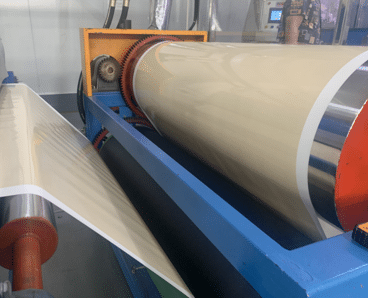

The application of silicone products in the power generation industry is mainly concentrated in the manufacture of wind turbine blades. By using molds made of silicone materials, not only the performance and reliability of wind turbine blades are improved, but also the production cost and cycle are reduced, which promotes the development of the wind power industry.

Oil & Gas Industry

Silicone seals, silicone products, have good insulation and sealing properties, high temperature resistance, corrosion resistance, and high-pressure resistance, and are used for sealing and protection of oil and gas pipeline joints and drilling equipment.

Marine industry

The application of silicone products in the marine industry is mainly reflected in improving the sealing, shock absorption, and wear resistance of ships.

The application of silicone products in the marine industry is mainly reflected in the following aspects:

- Improving the sealing of ships: Silicone products have good sealing performance and can be used for various sealing needs of ships, such as pipeline systems, engine systems, etc., to ensure the normal operation and safety of ships.

- Shock absorption performance: Silicone products as shock absorption materials, such as rubber pads, rubber springs, rubber shock absorbers, etc., can absorb vibration energy, reduce the impact of vibration on ship structures, and improve the comfort and safety of ships.

- Wear resistance: The wear resistance of silicone products can improve the wear resistance of ships and extend the service life of ships, especially in the application of key parts such as electrical systems and pipeline systems of ships, which can significantly improve the performance and reliability of ships.

Solar & Wind Energy

In the field of solar energy, the application of silicone products is mainly reflected in the manufacturing and installation of solar panels. Silicone is used for encapsulation, bonding, electronic potting and thermal conductivity to ensure the stable bonding of photovoltaic cells and aluminum shells. In addition, the elasticity of silicone can absorb vibrations without causing pressure on the battery, and it is UV resistant, which are all reasons for choosing silicone adhesives. The use of silicone products can improve the quality and efficiency of solar panels.

In the field of wind energy, silicone products also play an important role. In the manufacturing process of wind turbines, silicone fiberglass heat-resistant casing can effectively protect the generator from high temperatures, thereby improving the quality and efficiency of the generator. This casing has excellent high temperature resistance, corrosion resistance, wear resistance, good insulation performance, etc., which can effectively protect wind turbines from the influence of the external environment and extend their service life.

Defense Military

The application of silicone rubber products in military equipment includes but is not limited to rubber seals in the muzzle brake of artillery to ensure good sealing and normal operation of the muzzle device. In addition, silicone rubber cushions are also used in certain key connection parts of tank tracks to reduce vibration during driving and make the tank more stable when traveling. These silicone rubber products can effectively improve the performance and reliability of military equipment.

In terms of military facilities, the application of silicone rubber products includes bulletproof vests, tank tracks, aircraft tires, warship shock absorbers, etc. These products help to improve the durability and operating efficiency of equipment and facilities, provide protection, ensure smooth operation and extend service life.

In the research and development of national defense science and technology, silicone rubber products also play an important role. For example, silicone rubber products are used in some key parts of missiles and satellites to ensure sealing performance and reduce external impact. In addition, the potential application of recycled rubber in aerospace materials includes the manufacture of rocket propellants, space suit materials, and components of aerospace thermal control systems, showing its wide application prospects in the field of national defense and military industry.

In the field of military logistics, silicone rubber products also play an important role. For example, rubber products such as tires of transport vehicles, conveyor belts, and storage facilities such as seals and moisture-proof mats can ensure the safety of materials and improve transportation efficiency.

Electrical Wire & Cable:

Silicone products are widely used in wires and cables, covering insulation, conductivity, heating, waterproofing, shock proofing and many other aspects.

HVAC industry

Silicone products have good waterproof properties. Silicone products are needed in the design and maintenance of HVAC systems where sealing and insulation are required, thereby effectively preventing moisture from invading the system and protecting the system from damage.

Appliance industry

Silicone products are heat-resistant, moisture-proof, and shock-resistant. Silicone sealing rings are mainly used for the sealing and connection parts of various electrical products, such as washing machines, refrigerators, air conditioners, etc. They can effectively prevent water, dust and other external impurities from entering the interior of the appliance, ensure the normal operation of the components inside the appliance, and extend the service life of the appliance.

Lighting industry

Silicone products in the lighting industry are mainly silicone light strips and silicone night lights, which are used for interior decoration, commercial display, architectural lighting and vehicle lighting.

Digital Signage Display:

Digital signage & display industry requires silicone rubber gasket & seal which provide better performance as well as it should aesthetically look good.

Construction

Mold silicone: plays an important role in the production of architectural decorations. Through mold silicone, the texture and shape of materials such as sandstone and stone can be easily replicated to produce architectural decorations with a consistent appearance. This technology not only improves production efficiency but also makes the decorations more exquisite and realistic. Mold silicone is also widely used in the production of architectural decorations such as landscape stones, rockery and flower pots. It is lightweight, easy to carry and install, while maintaining a similar appearance and texture to real stone2.

Architectural decoration production: Silicone products are also widely used in the architectural decoration industry, including but not limited to the production of various decorations, such as replicating the texture and shape of materials such as sandstone and stone through mold silicone to produce architectural decorations with a consistent appearance. This technology not only improves production efficiency, but also makes the decorations more exquisite and realistic.

Chemical industry

Silicone products are widely used in the production of various chemical products, such as seals, pipes, valves, etc. Its advantages such as high temperature resistance, flexibility and corrosion resistance make it an important auxiliary tool in the chemical industry, providing reliable guarantee for the production of chemical products. In addition, silicone products are also used for the sealing of the ash door under the gasification furnace and the sealing of valves and valve stems in chemical plants, which improves production efficiency and safety by improving the operating environment and reducing the number of maintenance times.

Pharmaceutical & Medical

Silicone products are widely used in the pharmaceutical and medical fields, mainly including medical device manufacturing, artificial organ manufacturing, electronic packaging materials, seals and gaskets, as well as waterproof and anti-corrosion coatings.

The Advantages of silicone products

The advantages of silicone products mainly include high and low-temperature resistance, easy cleaning, long life, natural and environmental protection, soft and comfortable, various colors, electrical insulation, low-temperature resistance, electrical conductivity, weather resistance, thermal conductivity, and radiation resistance.

The Custom Silicone Products Process

Z.S.R Group work with the different industry brand owner, product development manager, product designer, product manager together offers the custom molded silicone products service with custom molded silicone products function, material, shape, sizes, custom logo, printing, brand, patterns, package label to the Residential, Commercial, Industrial using.

Custom Silicone Products

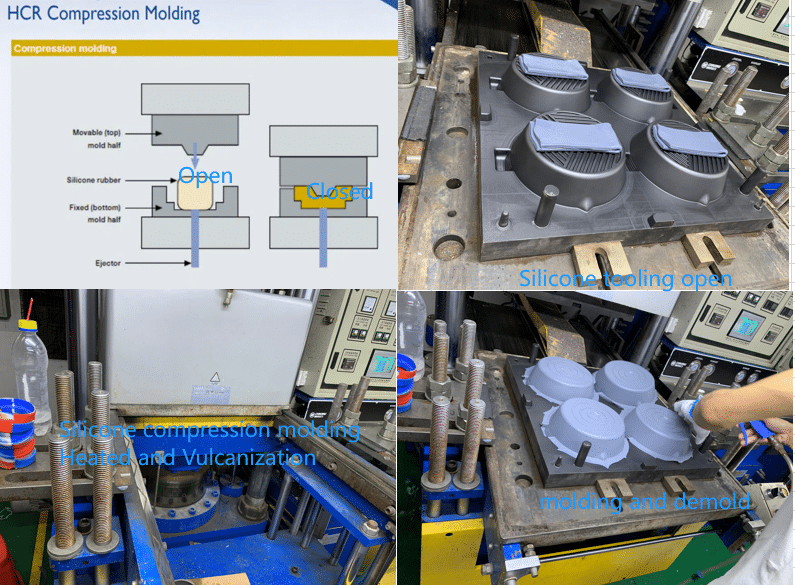

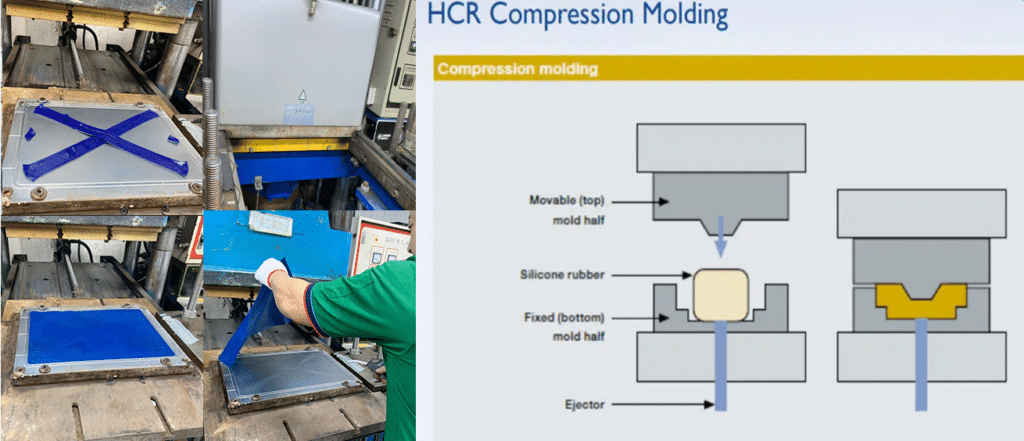

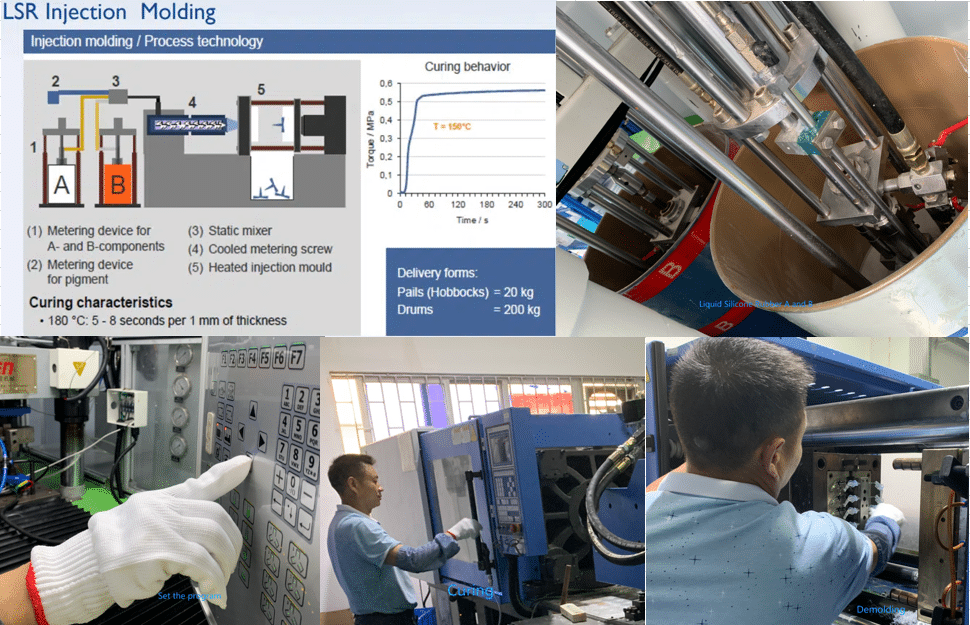

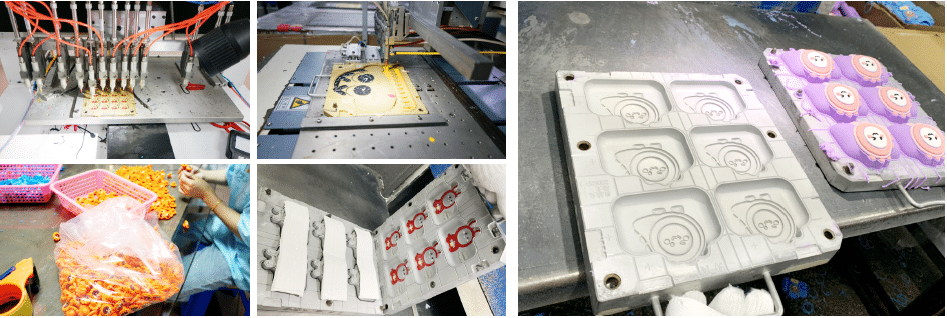

The production process of silicone products mainly includes design, batching, rubber mixing, molding, vulcanization, trimming, inspection, packaging and other links.

Silicone products Design: Determine the shape, size and structure of the silicone product according to the product use and performance requirements, while considering the production process and material selection.

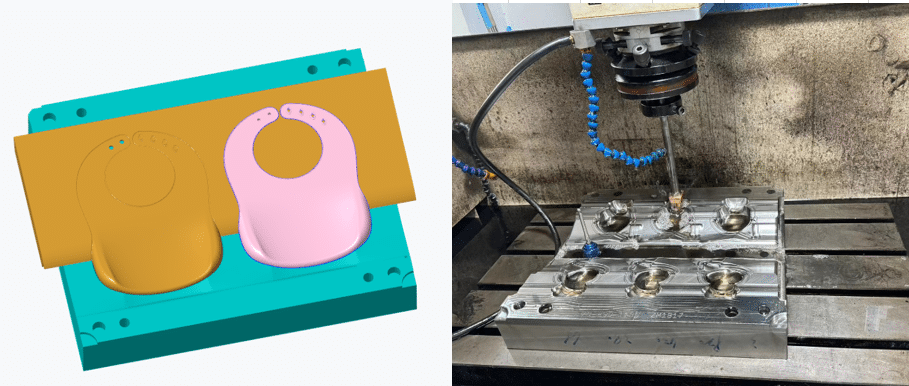

Silicone Mold making: Making the silicone tooling according to the silicone products shapes and structures.

Silicone Material prepared: Select suitable silicone materials according to product design requirements and mix them in a certain proportion to ensure the uniformity of the ingredients.

Silicone Rubber mixing: Heat the mixed silicone material to a flowing state, and control the temperature and time to maintain the material properties.

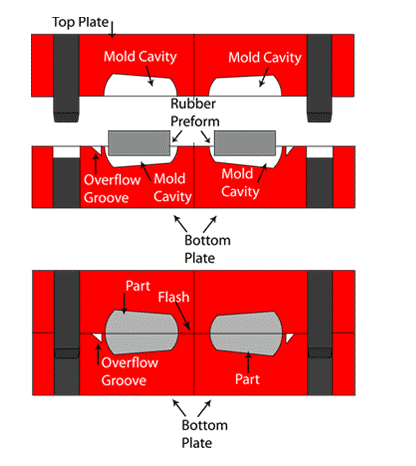

Silicone products Molding and Vulcanization: Pour the silicone material after rubber mixing into the silicone tooling mold, and fill the mold space by heating and pressurizing it to form the basic shape of the product. The vulcanizer in the silicone material reacts chemically with the rubber molecules through heating and pressure to form a cross-linked structure.

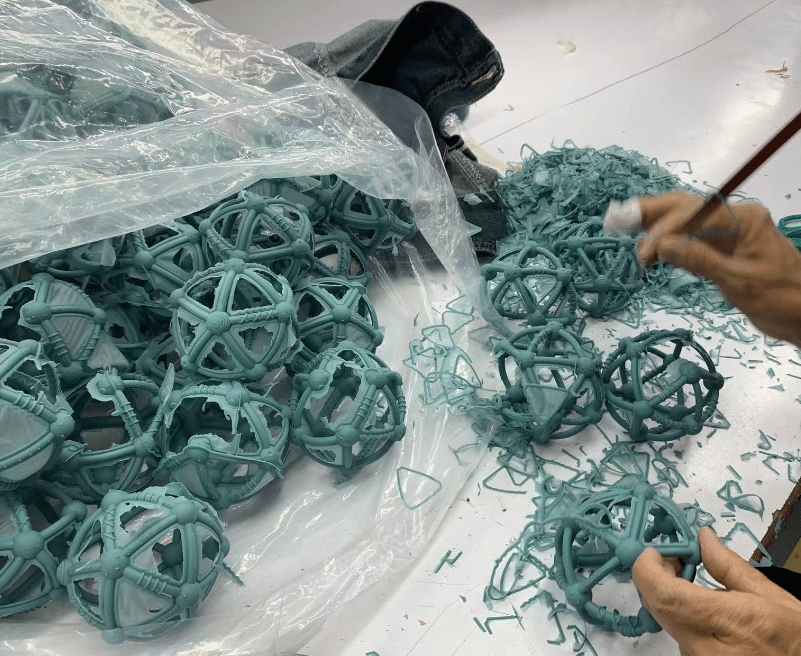

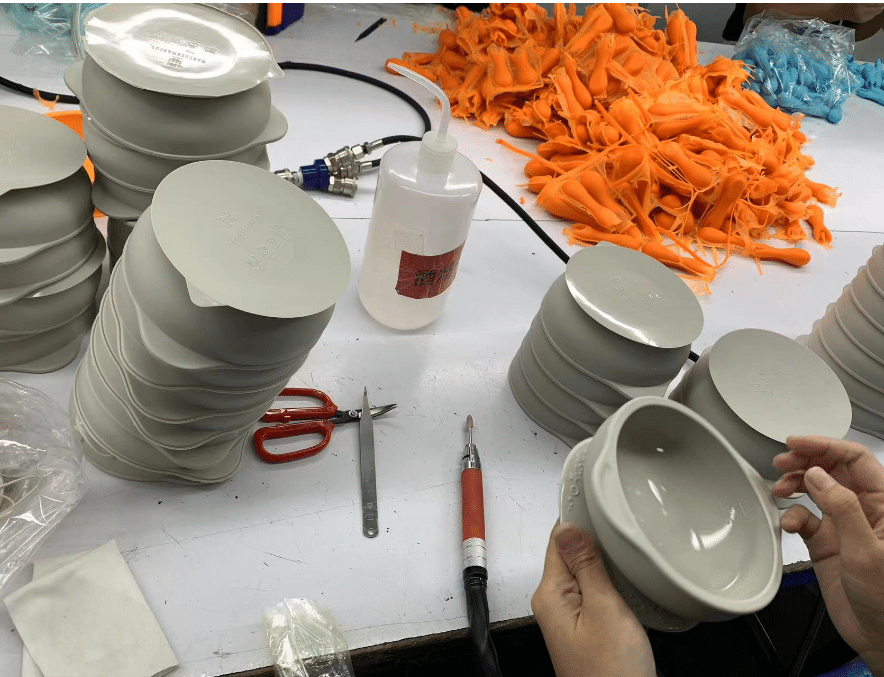

Trimming: Remove excess silicone material and burrs from the product to ensure the accuracy of product size and appearance.

Silicone products Inspection: Conduct quality inspection, including appearance inspection, size measurement and performance testing, to ensure that the product meets the design requirements and relevant standards.

Packaging: Packaging design is carried out according to product characteristics and transportation requirements to protect the safety of products during transportation and storage.

In addition, the production of silicone products may also include surface treatment such as silk screen printing and spraying to meet the special requirements of different products. During the entire production process, each link needs to be strictly controlled and managed to ensure product quality and performance

How to put your logo on silicone products

Putting a logo on silicone products include enhancing brand image, increasing product recognition, meeting market demand, and increasing product added value. The logo on silicone products can not only enhance brand image and market awareness, but also meet the personalized needs of consumers and increase the added value of products. It is an indispensable part of modern product design.

The logo on silicone products can be achieved through a variety of processes, such as mold engraving, printing LOGO, pad printing, etc. These processes have their own characteristics, and the most suitable method can be selected according to product requirements and budget.

More logo information: Custom Silicone Products Logo Service

Final Conclusion

Custom silicone products with for your project’s needs, company Logos, patterns, and text for Your Business (branding), Elevate Your Business with Custom Company Logo or pattern silicone products as

Corporate gifts. Discover our wide range of customizable options and elevate your brand presence with high-quality silicone rubber merchandise. Connect with ZSR Today to Enhance Your Brand’s Visibility with Custom silicone products to ensure your silicone products project success.

Related Reading

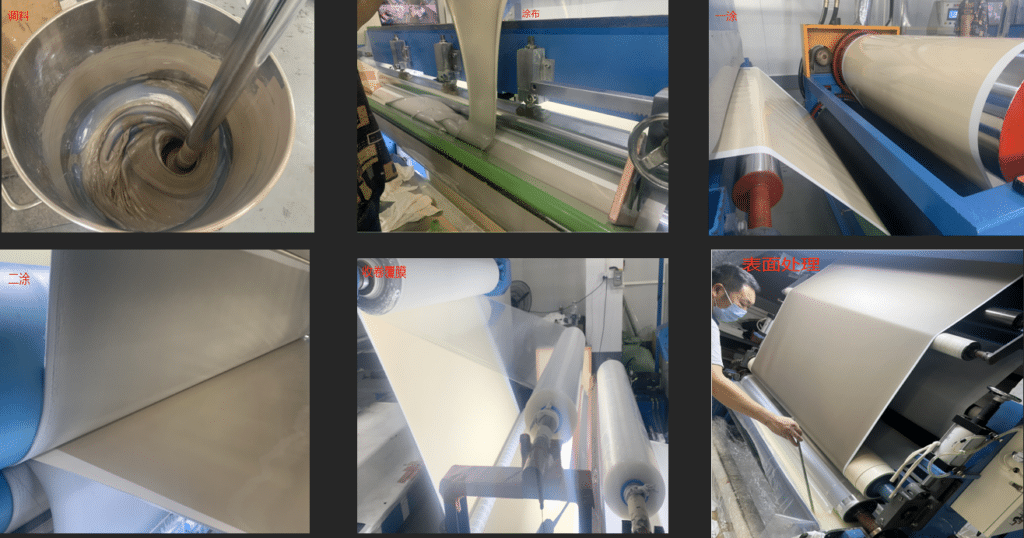

Silicone Leather Guide

Silicone Printing Guide – How to print Image or logo on silicone

How Put Logo Or Pattern On Silicone Rubber Products?

How To Print On Silicone Products?

How To Get The Colorful Silicone Products?

UV Resistant Silicone Rubber Products

Why should you turn to silicone food products?

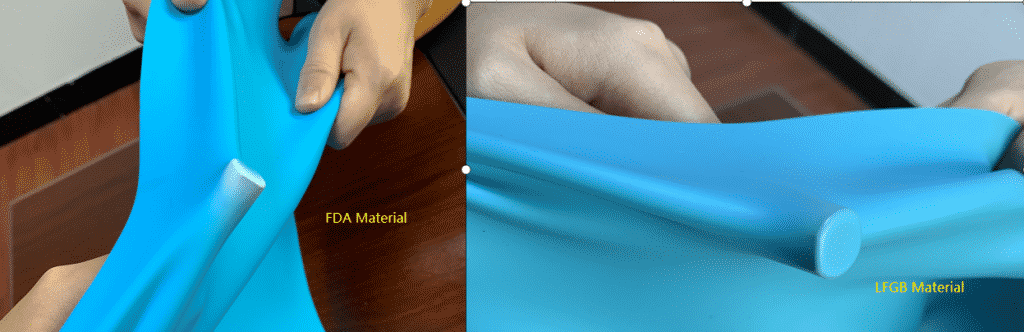

The best way to tell the difference of LFGB and FDA food silicone products?

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.