Is silicone rubber toxic/poisonous? A comprehensive explanation and selection guide?

Silicone is widely used in kitchen utensils, maternal and child products, beauty tools, 3C electronic accessories and other fields because of its high and low temperature resistance, safety, chemical inertness and softness.

However, as environmental protection, health and safety have become the mainstream consumer trends, more and more consumers are beginning to pay attention to the material source and composition of products. Silicone products are widely used because of their high temperature resistance.

But at the same time, questions such as “Is silicone toxic?”, “What is the difference between silicone rubber and plastic?”, and “Will it release harmful substances?” “Is silicone food safe? “ “Does silicone release toxins?” also frequently appear.

This article systematically disassembles the nature, safety, purchase standards, cleaning suggestions and how to avoid pitfalls of silicone, and helps companies and consumers identify truly safe silicone products from the source, and systematically analyzes whether silicone is safe from multiple angles, helping you to select materials scientifically and use them with peace of mind.

What is silicone? Is it toxic?

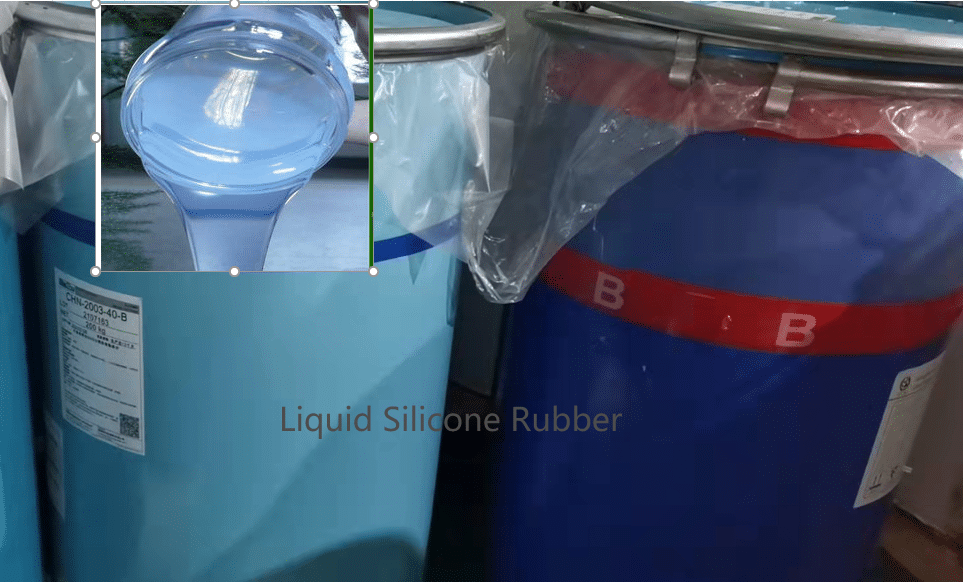

Silicone Rubber is a synthetic polymer material composed of silicon, oxygen, carbon, hydrogen and other elements. Its essence is polysiloxane, a thermosetting elastic material, colorless and odorless, resistant to high and low temperatures, oxidation and excellent stability.

Applications include food grade, medical grade, industrial grade, etc. Food grade and medical grade are strictly certified, do not contain BPA, heavy metals or plasticizers, and comply with FDA/EFSA regulations.

High-quality food grade/medical grade silicone itself is a non-toxic, harmless, non-volatile, and non-heavy metal residual material.

However, low-end inferior silicone (such as industrial waste mixed recycled silicone) may have problems with additive residues, strong odor, and release of harmful volatiles.

Why do people care about the toxicity of silicone?

Since it looks like plastic, users misunderstand its chemical properties. In fact, silicone is a biologically inert & non-toxic product: FDA-certified as GRAS, safe for food contact, anti-aging and chemical resistant, UV-resistant, anti-oxidation, can be used outdoors, medical, and kitchen.

Medical-grade silicone has passed cytotoxicity and genotoxicity tests.

However, a large number of inferior “filler silicones” appeared in the market in the early days, and the odor and yellowing of silicone caused users to question its safety.

Thermal stability: It can be used stably at -60℃ to 250℃ (up to 300℃ in the short term); it can be used in extreme temperatures and in the kitchen.

Z.S.R team work with products development companies, supply chain management, brands, chain store, retails to offer customized, private label molded silicone products. We are honored to provide high-quality silicone products and molding services to more than 500 clients from 30+ countries in the world.

Who is care silicone rubber toxic/poisonous?

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Contact Z.S.R to create your no toxic silicone products.

Custom Silicone Products | OEM/ODM Service

When should you pay attention to the toxicity of silicone?

For maternal and infant products, such as pacifiers, teethers, feeding spoons and other direct-intake products, it is recommended to check the certification and CFIA/EFSA/FDA logo for the first use.

Household kitchen utensils, baking trays, spatulas, kettle seals, high-temperature long-term use (baking, steaming, frying, etc.) extreme high temperatures.

Private contact products, such as menstrual cups, sexual health products, professional medical grade, medical catheters, masks, cannulas, etc., should assess the medical grade risk before use of implants; high-risk operations require doctor’s guidance.

Replace the product in time when it is found to be deformed, sticky, smelly, or color changed.

Industrial/electronics Industrial grade available non-contact with human body or low food safety risk.

Under what circumstances is it easy to produce “toxicity” risk?

- Use silicone products that have not been subjected to secondary vulcanization treatment.

- Choose low-end materials without FDA/LFGB certification.

- Use industrial silicone instead of food or medical use (extremely dangerous).

- Low-quality silicone releases impurities in a long-term high-temperature environment (such as microwaves and baking).

As long as compliant food-grade or medical-grade silicone is used, the above scenarios are safe and usable.

How to produce safety silicone products?

The production of safe silicone products requires ensuring the safety of raw materials, compliance of production processes and strict quality control, which are specifically divided into the following key links:

Raw material safety control

Use food grade or medical grade silicone raw materials, which must pass ISO certification or meet FDA standards, and avoid using carcinogens or harmful additives. Raw materials: high purity silica sand → metallic silicon → dimethyldichlorosilane → polymerized into silicone, the raw materials must be strictly screened and cleaned to remove impurities

Catalytic system: Medical/food grade uses “platinum catalytic system”, which is more environmentally friendly and safer

Production process compliance

LSR (liquid silicone injection molding): high precision, commonly used in medical/maternal and infant products, mixing and distribution : mix A/B component silicone in proportion, and ensure the safety of ingredients when adding auxiliary materials such as cross-linking agents and catalysts, and avoid using illegal additives.

HTV (solid molded silicone): used for kitchenware and industrial parts, molding and curing : the mold needs to be preheated to 170-200℃, and the injection pressure and temperature are precisely controlled to avoid bubbles.

Post-processing: Remove volatile impurities through high-temperature baking to ensure odor lessness and non-toxicity, including secondary vulcanization to remove low molecular weight compounds (such as benzene) to ensure no odor; trim burrs and clean impurities.

Quality control Testing standards: Test hardness, transparency, tensile rebound and other indicators, in compliance with environmental protection standards such as ROHS and REACH.

Finished product packaging: Use moisture-proof packaging to ensure that it is not damaged during transportation.

Temperature, pressure and other parameters must be monitored throughout the production process, and automated equipment must be used to reduce human errors.

As a silicone molding factory in China with 16 years, Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(48 sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber over molding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc.

Contact Z.S.R to create durable, compliant, brand-ready silicone products solutions.

How much of safety silicone material?

Ordinary industrial silicone is used for industrial sealing and non-food contact, with a unit price of about 0.15USD/g.

Food and kitchen/maternal and infant products need to be ingested or have high temperature effects, and food-grade silicone is used, with a unit price of 0.3-0.5USD/g.

Medical catheters, cannulas, nasal masks, etc. need to be used on the human body and disinfected at the same time, so medical-grade silicone is required, which is relatively expensive, with a unit price of more than 0.6-0.9USD/g.

How to choose safety silicone products?

Buy silicone products that are clearly marked as “Food grade” or “Medical grade platinum silicone” FDA (USA), LFGB (Germany), BPA-Free, REACH, NSF-51, ISO10993.

Platinum-cured silicone products are preferred, which have less residue.

Try to choose natural, odorless, translucent or light white silicone products.

Check whether it is allowed to be used in extreme high temperature, microwave or sterilization environments.

Judging color and smell: high-quality silicone has no obvious odor, is not sticky, and does not turn yellow.

How to control silicone products safety?

1. VOCs (volatiles) test and migration test must be carried out during production.

2. High temperature aging test, and strict control of product use temperature: home use ≤250℃, medical use ≤135℃ steam sterilization, avoid long-term exposure to oil, alcohol solvents or open flames, regularly clean and check material color and hardness changes.

3. Must meet the corresponding certification standards (FDA 21 CFR 177.2600, etc.)

Z.S.R Group’s quality ratings are sustained through the implementation of a rigorous quality control system. All the products quality is carefully verified through in-process inspection plans where products are constantly monitored for defects, damage, or any other inconsistencies. Every product package can then be traced back to the date the part was produced, the processes performed, and the materials employed.

How to clean and maintain silicone products?

More FAQs

1: Does silicone release microplastics?

Regular food-grade silicone does not produce microplastics. Extremely high temperatures or poor-quality products may release microparticles.

2: Will long-term ingestion of microparticles affect health?

Current evidence shows that daily contact is safe, but improper use environments should be avoided.

3: Will the implant leak?

Implant safety depends on quality and compliance, and requires doctor evaluation and regular inspections.

4: Can it be put in the dishwasher?

Yes, just put the silicone on the top layer away from the heating element.

5: Is bright-colored silicone safe?

It may contain pigments or fillers. It is recommended to use the original color option and check the test data.

6: Does silicone release toxins?

High-quality food-grade silicone will not, but inferior silicone may.

7: How to distinguish food-grade silicone?

Check whether it has FDA/LFGB certification and smell whether it has a pungent odor.

8: Can silicone be heated in a microwave?

Yes, silicone can withstand temperatures of 230°C, but it must be made of compliant materials.

9: Why does silicone have a smell?

Due to lack of secondary vulcanization or addition of low-quality fillers.

10: What is the difference between silicone and plastic?

Silicone is heat-resistant, elastic, BPA-free, and more environmentally friendly.

Summary

As a material, silicone rubber itself is a representative of safety, non-toxicity, environmental protection and reusability. However, there are a large number of low-quality silicone products on the market that are not treated or are disguised as food grade with industrial grade. It is these products that have caused consumers to worry about whether silicone is toxic. Food-grade and medical-grade silicone are widely proven to be safe, no-toxic, durable, and suitable for a variety of usage scenarios.

Potential risks: from low-quality non-certified products, aging under extreme conditions or implant failure.

Safety strategy: choose platinum food/medical-grade products, check certification, and master the correct use and cleaning methods;

Brand recommendation: Providing certification reports, clear labels and usage instructions are the key to winning trust and traffic.

What companies and consumers need to do is not to reject silicone products, but to learn to identify high-quality silicone products.

Only by choosing certified, sourced, tested, and reputable products can you truly enjoy the convenience, health and environmental protection value brought by silicone.

Are you looking for a no toxic silicone products manufacturer? Please contact Z.S.R today to get your design quote. From 3D CAD modeling to prototyping to Mass Silicone production molding, we will help you along the way!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.