Can Silicone Rubber be Compression molded?

There are three main forms of silicone rubber available:

Solid Silicone Rubber or High-Temperature Vulcanized, HTV – Solid silicone rubber contains polymers with a high molecular weight and relatively long polymer chains. They are available in an uncured form and required traditional rubber processing techniques.

Liquid Silicone Rubber, LSR – Liquid silicone rubber contains polymers of lower molecular weight and hence shorter chains. It has better flow properties. It is processed on specially designed injection molding and extrusion equipment.

Room Temperature Vulcanized, RTV – RTV silicone rubber is a type of silicone rubber made from one-part (RTV-1) or two-component (RTV-2) systems where their hardness range of very soft to medium. They are available for potting, encapsulations, sealants, etc.

Only solid silicone rubber can be compression molded.

Learn More About Silicone Molding Method And Process

Solid silicone rubber

silica sol liquid silicon sol is an important carrier of the material, the industry usually by ion-exchange method makes the silica sol sodium silicate sodium off the system. It is a translucent milky liquid, the content of silica in the sold goods is commonly 20% ~ 30%, and the highest is 50%, the colloidal particles diameter of 100 ~ 200 a, some items of 1300 a. A high concentration of silica sol is usually with the aid of trace amounts of sodium oxide to maintain its stability.

Colloidal silica drying after into porous solids. For example, in production by oxidation of propylene ammoniation of acrylonitrile (oxygen) phosphorus molybdenum – bi – / silicon oxide catalyst, is to contain active component solution mixed with silica sol, the spray drying method into the micro spherical catalyst.

The main properties of solid silicone Rubber:

- excellent transparency

- excellent tear strength (35N / mm)

- excellent spring-back, yellowing resistance and heat-resistant aging

- good thermal stability and weather ability (using temperature -60 C ~ 250 C)

- after mixing A / B at 20 C, the safe operation time in the sealed state is 5 days, and the safe operation time is shortened when the temperature rises.

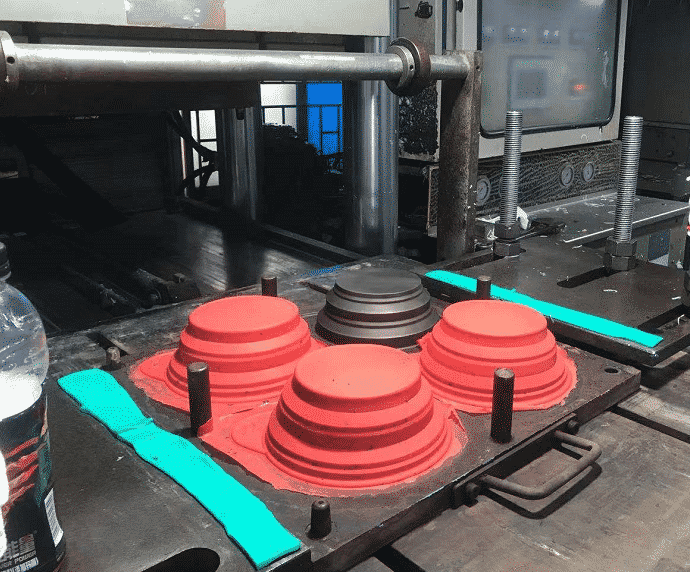

Solid silicone rubber is a transparent material, and a vulcanizing agent needs to be added during molding to speed up the vulcanization molding time. The solid silicone part is compression-molded, and after being kneaded by raw materials, it is cut into a size and thickness suitable for molding, and then placed in a silicone mold, manual demoulding.

Further Reading: Silicone Material

The solid silicone rubber compression molding: This enables the silicone to cure once introduced to heat. To add pigment to the silicone, the silicone must be mixed using a two-mill roll. This is a labor-intensive process that has the possibility of contamination of the silicone.

Once the material is pre-catalyzed and the pigment is added it is weighed and often shaped to the approximate size and configuration of the desired part. It is then placed directly into the mold cavity. The rubber is then compressed between the top and bottom plates. These plates are heated to melt the silicone and vulcanize (cure) the silicone.

ZSR Group has rich experience in producing Custom compression-molded silicone products with solid silicone rubber. We also can help select the right material (LSR or Solid silicone rubber) according to your project.

If you like the article or you need more information from us, please leave a message or contact us by info@consumersiliconeproducts.com, Any inquiry from you is welcome.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.