How is silicone produced? The whole process from sand to high-performance materials

Silicone rubber materials are currently widely used in maternal and child products, medical devices, kitchen utensils, auto parts and high-end electronic products. Are you curious about how silicone rubber materials can be transformed from ordinary sand on the ground into high-end materials? However, there are many misunderstandings in the market, such as “silicone is plastic” and “silicone comes from oil”.

For brands and purchasers, understanding the production process of silicone can: avoid the risk of inferior materials and quality disputes, scientifically select production processes to match product form and market positioning, improve channel communication and marketing expertise, and enhance certification capabilities, market reputation, and compliance. Based on global manufacturing processes and technical information, this article disassembles the core links from raw material preparation, chemical reactions to molding methods, and provides engineers, product managers and brand owners with a highly valuable reference material selection and process guide.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success. We have the capability for producing silicone tooling’s, producing HTV Silicone products, LSR molded silicone products, Molded multi-colored Silicone products. We also can Custom silicone tooling, Custom silicone molding, Custom Silicone compression molding, Custom LSR molding, Custom silicone Dripping injection dispensing (co-injection), Custom silicone fabric coating and curing molding.

Custom Silicone Products | OEM/ODM Service

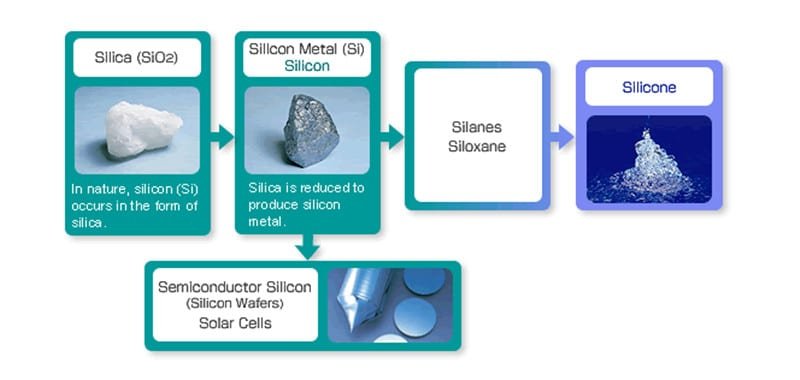

Silicone is not a petroleum plastic, but a natural silica sand (SiO₂) as a raw material, which is chemically synthesized into high-purity polysiloxane.

At the begin, let us see the trends of silicone rubber material?

The Trends of silicone rubber material

The silicone rubber industry has achieved remarkable results. With the leapfrog growth of consumption, the silicone rubber industry has begun to transform from high-performance special rubber to mass synthetic rubber, becoming one of the largest rubber varieties.

It is reported that from the perspective of rubber consumption, natural rubber accounts for 41.8%, styrene-butadiene rubber and butadiene rubber account for 28.4% in total, and silicone rubber is usually only used in a few non-tire fields such as building sealants and conductive buttons, accounting for only 6.4% of the total rubber consumption. Therefore, as silicone rubber replaces other rubber types in some non-tire segments, its consumption will surely increase exponentially and the market space will be further opened. In this regard, industry insiders also agree with the above view.

It is estimated that by 2015, silicone rubber will account for 10% to 15% of the total domestic rubber consumption, that is, the consumption of silicone rubber is expected to reach 1 million to 1.5 million tons, and by 2020, the proportion of silicone rubber in the total rubber consumption is expected to reach 20% to 33%, that is, the consumption of silicone rubber is expected to reach 3 million to 5 million tons. In other words, the development potential and long-term development of the silicone rubber industry are very attractive, and its rapid development will inevitably have a profound impact on upstream and downstream industries.

In fact, the linkage effect of upstream and downstream industries in the silicone rubber industry has begun to gradually emerge. Some experts pointed out that the biggest highlight of the development of the silicone rubber industry is that it can greatly increase the domestic self-sufficiency rate of rubber. According to statistics, if the proportion of silicone rubber in my country’s rubber consumption increases from 6.5% to 33% by 2020, then my country’s overall domestic self-sufficiency rate of rubber can be increased from about 50% to more than 80%, thereby greatly alleviating the tight supply of rubber and reducing the production costs of the rubber processing industry.

In 2021, my country’s total production capacity of high-temperature vulcanized silicone rubber is 1.292 million tons/year, a year-on-year increase of 25.60%; the output is about 850,800 tons, a year-on-year increase of 27.80%. In 2023, my country’s high-temperature vulcanized silicone rubber production capacity and output will be 1.81 million tons and 1.01 million tons respectively.

In 2021, my country’s liquid silicone rubber production capacity is 143,000 tons/year, a year-on-year increase of 26.20%, and the output reaches 93,000 tons, a year-on-year increase of 27.60%. By 2023, my country’s liquid silicone rubber production capacity and output will reach 250,000 tons and 130,000 tons respectively. With the upgrading of China’s manufacturing industry and the development of emerging industries, the output of liquid silicone rubber is expected to continue to grow.

It can be seen that the development of the silicone rubber industry is not just the single development of a single industry, but involves the common development of multiple industries, which has far-reaching significance for enhancing the profitability of the rubber processing industry and improving the quality level of rubber products.

What is silicone?

Silicone rubber refers to a rubber whose main chain is composed of alternating silicon and oxygen atoms, and the silicon atom is usually connected to two organic groups. Ordinary silicone rubber is mainly composed of siloxane chains containing methyl and a small amount of vinyl. The introduction of phenyl can improve the high and low temperature resistance of silicone rubber, while the introduction of trifluoropropyl and cyano can improve the heat and oil resistance of silicone rubber. Silicone rubber has good low temperature resistance and can generally still work at -55°C. After the introduction of phenyl, it can reach -73°C. The heat resistance of silicone rubber is also outstanding. It can work for a long time at 180°C, and can withstand several weeks or more at a temperature slightly higher than 200°C and still be elastic. It can instantly withstand high temperatures above 300°C. Silicone rubber has good air permeability and the oxygen permeability is the highest among synthetic polymers. In addition, silicone rubber also has the outstanding characteristics of physiological inertness and does not cause coagulation, so it is widely used in the medical field.

Silicone rubber is divided into heat-vulcanized type (high temperature vulcanized silicone HTV) including solid silicone (HTV/Solid) and liquid silicone (LSR).

Room temperature vulcanization type (RTV), of which room temperature vulcanization type is divided into condensation reaction type and addition reaction type.

High temperature silicone rubber is mainly used to manufacture various silicone rubber products,

while room temperature silicone rubber is mainly used as adhesive, potting material or mold.

The hot vulcanization type has the largest usage, and the hot vulcanization type is divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, the largest usage and product brand), methyl vinyl phenyl silicone rubber PVMQ (low temperature resistance, radiation resistance), and others include nitrile silicone rubber, fluorosilicone rubber, etc.

Silicone rubber manufacturers generally have dozens or even hundreds of varieties and brands, most of which are numbered according to product characteristics and uses, and some are classified according to vulcanization methods and chemical structures. According to the vulcanization temperature, silicone rubber can be divided into high-temperature vulcanized silicone rubber and room-temperature vulcanized silicone rubber. In terms of packaging, it can be divided into single-component and two-component room-temperature vulcanized silicone rubber. According to the degree of polymerization, silicone rubber can also be divided into mixed silicone rubber and liquid silicone rubber.

In Z.S.R Group, our core service is silicone molding service with High temperature vulcanized silicone rubber.

Z.S.R’s Precision Silicone mold /tooling shop 6 sets EDM , 10 sets CNC,Silicone Compression molding(48sets), Silicone over-molding, Liquid Silicone Rubber Injection molding(12 sets): LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding(13 lines), capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc. Custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality silicone products for different industry application from industrial, consumer, commercial to medical.

Contact Z.S.R to kick off your silicone projects.

High temperature vulcanized silicone rubber

High temperature vulcanized silicone rubber refers to the process of polysiloxane becoming an elastomer through high temperature (110-170℃) vulcanization molding. It mainly uses high molecular weight polymethylvinylsiloxane as raw rubber, mixed with reinforcing fillers, vulcanizers, etc., and vulcanized into elastomers under heating and pressure. The reinforcement of silicone rubber is mainly various types of white carbon black, which can increase the strength of vulcanized rubber by dozens of times. Sometimes, in order to reduce costs or improve the properties of rubber materials and give vulcanized rubber various special properties, various corresponding additives are also added. Vulcanizers are various organic peroxides or addition reaction catalysts.

Raw rubber types and preparation

Raw rubber types mainly include methyl silicone rubber, methyl vinyl silicone rubber, methylphenylvinyl silicone rubber and fluorosilicone rubber, as shown in the figure. In addition, phenylene groups can also be introduced into the main chain. The largest amount is methylvinyl silicone raw rubber. Due to the introduction of the active group vinyl for crosslinking, the crosslinking efficiency of silicone raw rubber crosslinked with peroxide is greatly improved. Almost all commercial silicone rubbers contain a certain amount of vinyl.

In industry, silicone rubber is mainly produced by base-catalyzed polymerization and acid-catalyzed polymerization. KOH and temporary catalysts [(CH3)4NOH, (n-C4H9)4POH] are more commonly used.

Processing and molding

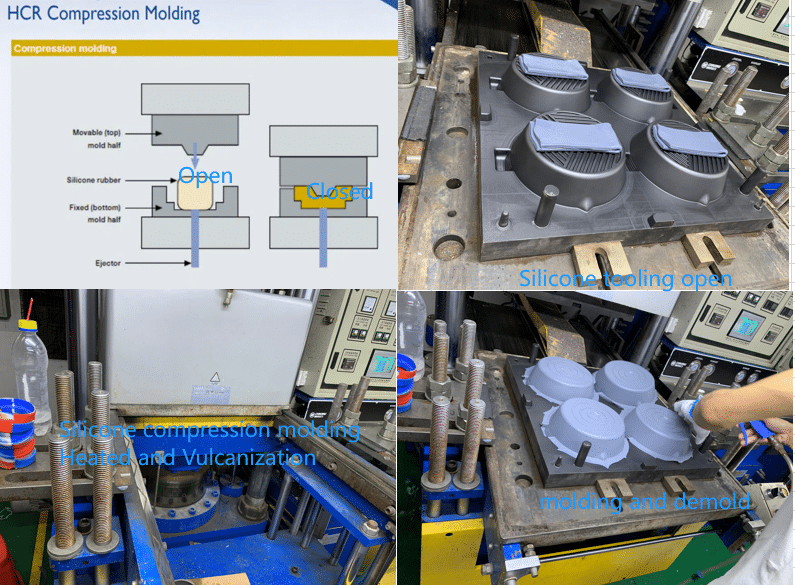

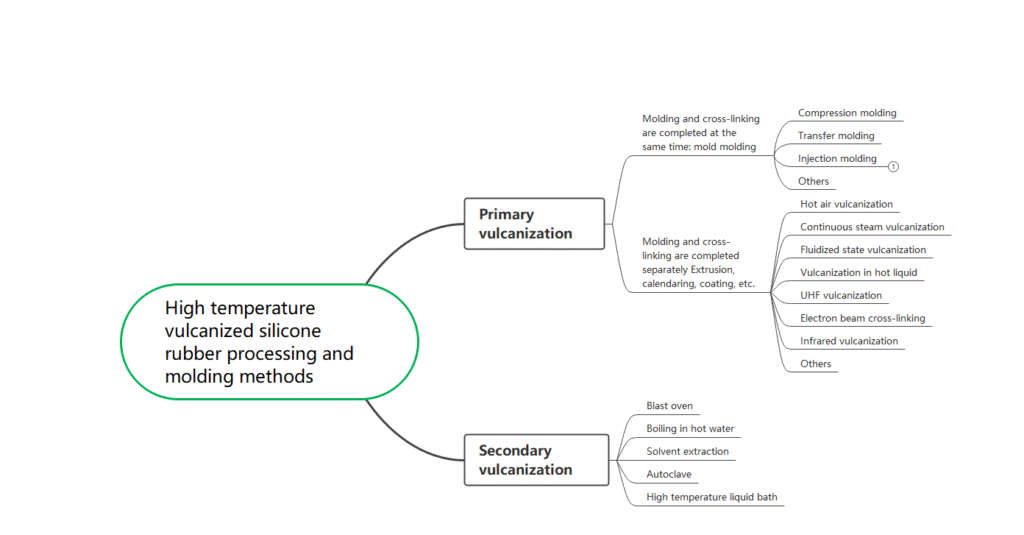

The processing and molding method is shown in the figure. The purpose of primary vulcanization is to carry out cross-linking reaction of polymer chains; the purpose of secondary vulcanization is to carry out supplementary cross-linking, drive off the decomposition products of vulcanizing agents and other volatile compounds to stabilize the various properties of vulcanized rubber. Commonly used equipment includes open rubber mixers, kneading machines and vacuum mixers.

Main properties of High temperature vulcanized silicone rubber

(1) High temperature performance. The most notable feature of silicone rubber is its high temperature stability. Although the strength of silicone rubber at room temperature is only half of that of natural rubber or some synthetic rubber, it can still maintain a certain degree of flexibility, resilience and surface hardness in a high temperature environment above 200°C, and its mechanical properties do not change significantly.

(2) Low temperature performance. The glass transition temperature of silicone rubber is generally -70~-50°C, and special formulas can reach -100°C, indicating that it has excellent low temperature performance. This is of great significance to the aviation and aerospace industries. (3) Weather resistance The Si-O-Si bond in silicone rubber is very stable to oxygen, ozone and ultraviolet rays, and has excellent weather resistance without any additives.

(4) Electrical properties. Silicone rubber has excellent insulation properties, and its corona resistance and arc resistance are also very good.

(5) Physical and mechanical properties. The physical and mechanical properties of silicone rubber at room temperature are worse than those of general-purpose rubber, but at high temperatures of 150°C and low temperatures of -50°C, its physical and mechanical properties are better than those of general-purpose rubber.

(6) Oil and chemical reagent resistance. Ordinary silicone rubber has moderate oil and solvent resistance.

(7) Gas permeability. At room temperature, the permeability of silicone rubber to air, nitrogen, oxygen, carbon dioxide and other gases is 30-50 times higher than that of natural rubber.

(8) Physiological inertness. Silicone rubber is non-toxic, tasteless, odorless, non-adhesive to human tissue, has anti-coagulant effect, and has very little reactivity to body tissue. It is particularly suitable as a medical material.

Room temperature vulcanized silicone rubber

The main difference between room temperature vulcanized silicone rubber and high temperature vulcanized silicone rubber is that it is based on polysiloxane with a smaller molecular weight. It can be vulcanized into an elastomer at room temperature or slightly heated under the action of a crosslinker and a catalyst. Room temperature vulcanized silicone rubber consists of a base rubber, a crosslinker, a catalyst, a filler, etc. It can be divided into two types of packaging: one-component and two-component.

Base rubber

The base rubber is preferably a hydroxyl-terminated polydimethylsiloxane, and polymethylsiloxane containing alkoxy or other active groups can be used for special purposes. α,ω-dihydroxy polysiloxane is the base rubber of two-component and one-component condensation-type silicone rubber, and is usually called 107 rubber in the market.

One-component room temperature vulcanized silicone rubber

One-component room temperature vulcanized silicone rubber is one of the main products of condensation-type silicone rubber. It is made of a base rubber, a filler, a crosslinker, a catalyst, a plasticizer, a pigment, etc. The base rubber is α,ω-dihydroxy polysiloxane. The filler plays the role of reinforcement, volume expansion and special properties. There are many kinds of crosslinking agents, catalysts and other fillers, depending on market demand and product performance.

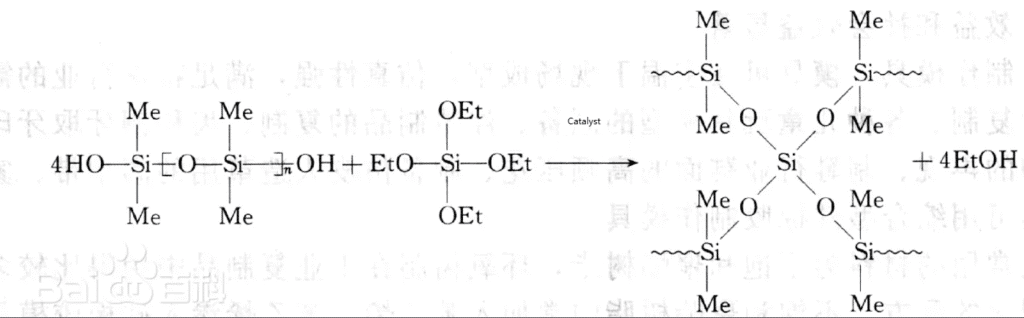

Two-component room temperature vulcanized silicone rubber

Except for the crosslinking agent, the other ingredients of two-component room temperature vulcanized silicone rubber are the same as those of single-component. Two-component room temperature vulcanized silicone rubber often uses ethyl orthosilicate or polyethyl silicate as a crosslinking agent, the latter of which has a high crosslinking speed. The vulcanization reaction is shown in the figure.

Applications of room temperature vulcanized silicone rubber

(1) Construction industry. Used for bonding glass and metal curtain walls, roof embedding, door and window sealing, and bonding and sealing of various pools and tiles.

(2) Electronics industry. Used as encapsulation and potting materials for electronic and electrical components, which are moisture-proof, shock-resistant, impact-resistant, resistant to sudden temperature changes and chemical corrosion.

(3) Molds. The excellent simulation and good demoulding properties of silicone rubber make it widely used in the soft mold industry.

(4) Automobiles, ships and aviation. Used as automotive in-situ molded gaskets, window seals, and anti-corona for electronic and electrical connectors, etc.

Addition-type liquid silicone rubber

Addition-type liquid silicone rubber is mainly made of polydimethylsiloxane containing terminal vinyl groups as the base rubber, polymethylsiloxane containing dimethyl segments and methyl hydrogen segments as the crosslinking agent, and platinum complex as the crosslinking catalyst. Under the action of the catalyst, the rubber undergoes an addition reaction at room temperature or under heating to obtain a silicone rubber with a network structure.

Main Varieties of silicone

There are many ways to classify silicone rubber.

Usually, it is divided into solid silicone rubber and liquid silicone rubber according to the form before curing;

According to the vulcanization temperature, it can be divided into room temperature vulcanized silicone rubber and high temperature vulcanized silicone rubber;

According to the different monomers used, it can be divided into methyl vinyl silicone rubber, methyl phenyl vinyl silicone rubber, fluorosilicone, nitrile silicone rubber, etc.;

According to the different performance and uses, it can be divided into general type, ultra-low temperature resistant type, ultra-high temperature resistant type, high strength type, oil resistant type, medical type, etc.

A brief introduction to commonly used silicone rubbers

Dimethyl silicone rubber

Dimethyl silicone rubber is referred to as methyl silicone rubber:

To prepare high molecular weight linear dimethyl polysiloxane rubber, high purity raw materials are required. To ensure the purity of the raw materials, the industry usually first hydrolyzes and condenses dimethyl dichlorosilane with a content of more than 99.5% in an ethanol-water medium under acid catalysis, and separates the difunctional siloxane tetramer, namely octamethylcyclotetrasiloxane, and then the tetracyclic body is used under the action of a catalyst to form a high molecular linear dimethyl polysiloxane.

Dimethyl silicone rubber raw rubber is a colorless and transparent elastomer, which is usually vulcanized with highly active organic peroxides. Vulcanized rubber can be used in the range of -60~+250℃. Dimethyl silicone rubber has low vulcanization activity and large high temperature compression permanent deformation. It is not suitable for making thick products. Thick products are difficult to vulcanize and the inner layer is also prone to blistering. Since the performance of methyl vinyl silicone rubber containing a small amount of vinyl is better than that of dimethyl silicone rubber, dimethyl silicone rubber has been gradually replaced by methyl vinyl silicone rubber. Other types of silicone rubber currently produced and used contain more or less other difunctional siloxane structural units in addition to dimethyl siloxane structural units, but their preparation methods are essentially the same as those of dimethyl silicone rubber. Their preparation methods are generally to hydrolyze and condense a certain difunctional silicon monomer under conditions that are conducive to the formation of a ring body, and then add octamethylcyclotetrasiloxane in the required proportion, and then react together under the action of a catalyst to obtain the obtained product.

Methyl vinyl silicone rubber

Methyl vinyl silicone rubber is referred to as vinyl silicone rubber.

This type of rubber contains a small amount of vinyl side chains, so it is easier to vulcanize than methyl silicone rubber, so that it has more types of peroxides available for vulcanization and can greatly reduce the amount of peroxide used. Compared with dimethyl silicone rubber, the use of silicone rubber containing a small amount of vinyl can significantly improve the compression set resistance. The low compression set reflects that it has better support at high temperature as a seal, which is one of the requirements that O-rings and gaskets must have. Methyl vinyl silicone rubber has good process performance and is easy to operate. It can be made into thick products and the surface of extruded and calendered semi-finished products is smooth. It is a commonly used silicone rubber.

Methyl phenyl vinyl silicone rubber

Methyl phenyl vinyl silicone rubber is referred to as phenyl silicone rubber. This kind of rubber is obtained by introducing diphenyl siloxane chain segments or methyl phenyl siloxane chain segments into the molecular chain of vinyl silicone rubber.

According to the different phenyl content (phenyl: silicon atom) in silicone rubber, it can be divided into low phenyl, medium phenyl and high phenyl silicone rubber. When the rubber crystallizes or approaches the glass transition point or the two situations overlap, the rubber will become rigid. The introduction of an appropriate amount of large-volume groups to destroy the regularity of the polymer chain can reduce the crystallization temperature of the polymer. At the same time, since the introduction of large-volume groups changes the interaction between polymer molecules, the glass transition temperature can also be changed. Low phenyl silicone rubber (C6H5/Si=6~11%) has excellent low temperature resistance due to the above reasons, and has nothing to do with the type of phenyl monomer used. The brittle temperature of the vulcanized rubber is -120℃, which is the rubber with the best low temperature performance today. Low phenyl silicone rubber has the advantages of vinyl silicone rubber, and the cost is not very high, so it has a tendency to replace vinyl silicone rubber. When the phenyl content is greatly increased, the rigidity of the molecular chain will increase, resulting in a decrease in cold resistance and elasticity, but the ablation resistance and radiation resistance will be improved. The phenyl content of C6H5/Si=20~34% is medium phenyl silicone rubber with ablation resistance, and high phenyl silicone rubber (C6H5/Si=35~50%) has excellent radiation resistance.

Nitrile silicone rubber

Fluorosilicone rubber is a type of silicone rubber with fluoroalkyl groups introduced into the side chain. Commonly used fluorosilicone rubbers are fluorosilicone rubbers containing methyl, trifluoropropyl and vinyl.

Fluorosilicone has good heat resistance and excellent oil and solvent resistance. For example, it has good stability at room temperature and high temperature for aliphatic hydrocarbons, aromatic hydrocarbons, chlorinated hydrocarbons, various petroleum-based fuel oils, lubricating oils, hydraulic oils and some synthetic oils, which are beyond the reach of pure silicone rubber. Fluorosilicone rubber has good low-temperature performance, which is a great improvement over pure fluororubber. The temperature range for trifluoropropyl-containing fluorosilicone rubber to maintain elasticity is generally -50℃~+200℃. Its high and low temperature resistance is worse than that of vinyl silicone rubber, and it will produce toxic gases when heated to above 300℃. It is much worse than vinyl silicone rubber in terms of electrical insulation performance. Adding an appropriate amount of low-viscosity hydroxyl fluorosilicone oil to the rubber compound of fluorosilicone rubber, heat-treating the rubber compound, and then adding a small amount of vinyl silicone rubber can significantly improve the process performance, which is conducive to solving the problems of rubber compound sticking to the roller and serious storage structure, and can extend the effective service life of the rubber compound. When methylphenylsiloxane chain segments are introduced into the above-mentioned fluorosilicone rubber, it will help improve the low-temperature resistance and have good processing performance.

Nitrile silicone rubber is a type of silicone rubber with nitrile alkyl (generally β-nitrile ethyl or γ-nitrile propyl) introduced into the side chain. The introduction of polar nitrile groups improves the oil resistance and solvent durability of silicone rubber, but its heat resistance, electrical insulation and processability are reduced.

The type and content of nitrile alkyl have a great influence on the performance of nitrile silicone rubber. For example, silicone rubber containing 7.5% γ-nitrile propyl has similar cold resistance to low phenyl silicone rubber, and its oil resistance is better than that of low phenyl silicone rubber. When the γ-nitrile propyl content increases to 33~50% gram molecule, the cold resistance is significantly reduced, the oil resistance is improved, and the heat resistance is 200℃. If β-nitrile ethyl is used instead of γ-nitrile propyl, the heat resistance of nitrile silicone rubber can be further improved.

Phenylene and phenylene ether silicone rubber

Phenylene silicone rubber is a type of silicone rubber with phenylene groups introduced into the main chain of polysiloxane.

Due to the introduction of phenylene groups, the radiation resistance of silicone rubber is greatly improved. At the same time, due to the presence of aromatic rings, the rigidity of the molecular chain is increased, the flexibility is reduced, the glass transition temperature is increased, the cold resistance is reduced, and the tensile strength is increased. Phenylene silicone rubber has excellent high temperature resistance and radiation resistance, and the high temperature resistance can reach 250~300℃. It also has good dielectric properties and moisture-proof, mildew-proof and water vapor-proof properties. In the raw rubber composition of phenylene silicone rubber, it is suitable when the phenylene content is 60%, the phenyl content is 30%, and the methyl content is 10% (vinyl content is 0.6%). In this case, the vulcanized rubber has good comprehensive properties.

The disadvantage of phenylene silicone rubber is that the low temperature performance is poor, and the brittle temperature is -25℃, which affects its application in some aspects. The low temperature performance of phenylene ether silicone rubber is far better than that of phenylene silicone rubber, and the brittle temperature is -64~70℃.

Phenylene ether silicone rubber is a polysiloxane with phenylene ether and phenylene groups introduced into the main chain of the molecule.

Phenylene silicone rubber has good mechanical properties. Its general tensile strength can reach 150~180 kg/cm2 (i.e. 14.7~17.7Mpa), which is much higher than the strength of vinyl silicone rubber. It also has excellent radiation resistance and is better than phenylene silicone rubber. It can withstand long-term 250℃ hot air aging and still has high strength after aging. Although the low-temperature performance of phenylene silicone rubber is worse than that of vinyl silicone rubber, it is much better than that of phenylene silicone rubber. Its dielectric properties are close to those of vinyl silicone rubber, but phenylene silicone rubber has poor oil resistance, and is not resistant to non-polar petroleum-based oils or polar synthetic oils (such as 4109 diester synthetic lubricants and phosphate ester hydraulic oils. In short, phenylene silicone rubber has higher strength and radiation resistance than vinyl silicone rubber, similar high temperature resistance and dielectric properties, but poor low temperature performance, oil resistance and elasticity. Phenylene silicone rubber has good processing performance and can be used to manufacture molded products and extruded products with special requirements.

Medical Area

Among many synthetic rubbers, silicone rubber is the best. It is odorless and non-toxic, not afraid of high temperature and cold, and is “calm” and “unchanged” at 300 degrees Celsius and minus 90 degrees Celsius, and still retains its original strength and elasticity. Silicone rubber also has good electrical insulation, oxygen resistance and aging resistance, light resistance and aging resistance, mildew resistance, chemical stability, etc. Due to these excellent properties, silicone rubber has played an important role in modern medicine. With the joint cooperation of hospitals, scientific research institutions and factories, a variety of silicone rubber medical supplies have been successfully trial-produced.

Silicone rubber anti-noise earplugs: comfortable to wear, can well block noise and protect the eardrum.

Silicone rubber fetal head suction device: easy to operate, safe to use, can be deformed according to the size of the fetal head, the fetal scalp will not be sucked up during suction, which can avoid scalp hematoma and intracranial injury and other disadvantages, and can greatly reduce the pain of dystocia during delivery.

Silicone rubber artificial blood vessels: have special physiological functions, can be “close” to the human body, and the human body does not reject it. After a certain period of time, it will be completely integrated with human tissue and has excellent stability.

Silicone rubber eardrum patch: the sheet is thin and soft, with good smoothness and toughness. It is an ideal material for repairing the eardrum, and it is easy to operate and has good results.

In addition, there are silicone rubber artificial trachea, artificial lungs, artificial bones, silicone rubber duodenal tubes, etc., all of which have very ideal effects.

What is the process of silicone produced?

The production process of silicone rubber is divided into three stages: raw material preparation, polymerization synthesis and processing and molding, mainly including core processes such as quartz sand refining, siloxane polymerization and high temperature/room temperature vulcanization.

Raw material preparation and monomer synthesis

The basic raw material of silicone rubber comes from quartz sand (SiO₂), which is carbon-thermal reduced to generate metallic silicon, and then reacts with chloromethane to synthesize methylchlorosilane monomer. The hydrolysis and polycondensation reaction convert the monomer into polysiloxane to form the molecular main chain structure of silicone rubber.

Polymerization synthesis process

The synthesis of silicone rubber is divided into two main types:

- High temperature vulcanized silicone rubber (HTV).

- Methylcyclosiloxane (D₃, D₄) is used for ring-opening polymerization under alkaline catalysts (such as KOH).

Reaction conditions: 150-200℃ vacuum dehydration, lasting 6-12 hours to form raw rubber with a molecular weight of 400,000-800,000.

Key processes include catalyst neutralization and oligomer removal (residue <1%).

Room temperature vulcanized silicone rubber (RTV).

Condensation type (RTV-1): Moisture curing of hydroxyl-terminated silicone oil and crosslinking agent (such as methyltriacetoxysilane).

Addition type (RTV-2): Vinyl silicone oil and hydrogen-containing silicone oil are crosslinked by platinum catalyst.

Who and why care silicone produced process?

The production process of silicone raw materials affects its purity, stability and safety, which in turn determines the quality of silicone products. Therefore, from the perspective of quality control, as R&D engineers in silicone molding processing plants, we need to understand the production process of silicone raw materials.

The input, output and unit price of silicone raw materials depend on the type of silicone process. As the purchasing/quality manager and product manager of the factory, understanding silicone raw materials will help us choose the right processing method and optimize the cost structure of silicone products.

As a brand operator of silicone products, brand owners, cross-border e-commerce sellers, food-grade and medical-grade silicone must use high-purity materials and clean processes. Understanding the production process of silicone raw materials will help us choose the right silicone raw materials, which will facilitate the international compliance requirements of silicone products such as FDA/LFGB. Improve customer trust in our brand.

It is beneficial for our silicone product factory to establish a standard system from raw materials to finished products, so that our products are traceable.

When and where you need attention silicone produced?

For silicone products, in the early stage of product development, define the purpose (such as medical grade vs industrial grade) and the corresponding post-processing method. At the same time, determine the mold design and material formula.

How to produce silicone products?

For silicone products, which need to be exported to Europe and the United States/maternal and child/medical products to sensitive markets, special attention should be paid to the raw materials of silicone. At the same time, the catalytic cross-linking system (platinum vs peroxide) needs to be formulated according to the purpose.

When the product has quality problems such as odor and discoloration, it needs to be traced. OEM factories/testing centers need to test finished product inspection, subpackaging and customization services.

Detailed explanation of the entire production process of silicone products

1. Raw material preparation

Silicone raw materials are natural quartz (SiO₂) → metallic silicon → methylchlorosilane → polymerization reaction to form a polysiloxane skeleton.

High-quality suppliers such as Dow, Wacker, Shin-Etsu provide high-purity methyl silicone oil, hydrogen silane, VMQ and other basic rubber materials.

2. Formula design

Mix the formula according to the needs of silicone products:

HTV: Add white carbon black, reinforcing agent, thickener, suitable for compression molding or extrusion after vulcanization.

LSR: Use platinum catalysis and two-component mixing, suitable for rapid injection vulcanization.

RTV: Use room temperature cross-linking system, suitable for sealants or mold materials.

Engineers need to determine indicators such as hardness, rebound rate, temperature resistance range, and tear resistance.

3. Molding process

Compression molding (HTV): First press the material and then heat and vulcanize, suitable for large structural parts.

Injection molding (LSR): Automated and efficient, mostly used for medical and complex maternal and child structures.

Room temperature vulcanization (RTV): dispensing or manual vulcanization, flexible application.

4. Vulcanization process

HTV: peroxide vulcanization, cooling demolding is required.

Extrusion molding.

Used for linear products such as silicone tubes and sealing strips, with high production efficiency and precise dimensions.

Compression molding.

Suitable for precision parts such as sealing rings, the mold temperature needs to be controlled at 160-180℃, and the pressure is 8-

Calendering molding: Production of sheet products such as silicone plates and gaskets, the thickness tolerance can be controlled at ±0.05mm

LSR: platinum catalytic vulcanization, which can be completed in a shorter cycle. Injection molding.

Manufacturing high-precision products such as pacifiers, the injection temperature is usually 170-190℃, and the mold temperature is 140-160℃

RTV: slow vulcanization at room temperature or under heating.

5. Post-processing steps

Remove burrs and re-vulcanize: Use 200-250℃ post-curing process to eliminate the decomposition products of the vulcanizing agent and improve the thermal stability of the material.

Surface cleaning/static remover

Packaging, performance testing, shipment inspection.

How to control silicone quality?

How much of silicone we need?

According to statistics from the China Association of Automobile Manufacturers, in 2012, automobile production and sales reached 19.2718 million and 19.3064 million respectively, up 4.63% and 4.33% year-on-year respectively, and the amount of silicone rubber used in the automotive industry reached about 20,000 tons. According to the latest research of Guanyan Tianxia, increasing the amount of silicone materials used in automotive parts can greatly improve the safety performance of automobiles. Therefore, the increase in automobile production and per-vehicle usage will promote the increase in the demand for silicone rubber in the automotive industry. The state encourages the development of independent brands of automobiles and the realization of independent key automobile parts. The “2012 Annual Catalog of Vehicle Models Selected for Official Vehicles of Party and Government Agencies (Draft for Comments)” provides guarantees for independent brands to expand their market share in government procurement and change the current situation in which domestic government procurement is mainly based on joint venture brand products. Promoting the development of independent brands and the prosperity of the domestic automobile industry will provide strong guarantees for the application of automotive glue. It is predicted that in the next three years, the room temperature vulcanized silicone rubber in my country’s automotive industry will grow at an average annual rate of 20%.

In addition, silicone rubber is the most important non-petroleum-based synthetic rubber, accounting for about 98% of the consumption of non-petroleum-based synthetic rubber. However, due to the sharp rise in oil prices and the breakthroughs made by my country in the production technology of silicone monomers, the key raw material of silicone rubber, the production technology of silicone monomers was monopolized by several multinational companies before 2005, but my country has now developed into the world’s largest silicone monomer country. These two reasons have caused the price of silicone rubber to be lower than that of petroleum-based synthetic rubber since 2011, only about 80% to 90% of bulk petroleum-based rubber, becoming the cheapest synthetic rubber and starting to replace petroleum-based synthetic rubber on a large scale. This will greatly expand the market space of the silicone industry and drive the consumption of other silicone products such as silicone oil, silane coupling agent and silicone resin.

How to choose the right silicone raw material?

First, we need to choose the right material according to the purpose of silicone products:

- For kitchenware

- We can choose food-grade LSR or food-grade mixed silicone rubber

- For medical use

- We must choose medical-grade platinum-vulcanized LSR

- For industrial seals

- We can choose ordinary HTV.

Second, we need to choose the filler ratio and physical property gradient (hardness, elasticity, conductivity, etc.) according to the performance requirements of our products.

Third, we can determine the injection molding or compression molding or extrusion processing path according to the required output and batch of our products.

More FAQs

1: Is silicone made from petroleum?

No. The raw material of silicone comes from natural quartz, which is processed to high purity and is not equivalent to petroleum plastic.

2: What is the relationship between silicone and silica sand?

Silica gel is purified from natural silica sand (mainly SiO₂) to obtain metallic silicon, which is then processed and synthesized.

3: Are food-grade silicone raw materials safe?

It requires upstream platinum catalysis, low-volatile raw materials, and FDA/LFGB and other test reports. If there are the above reports, it is basically safe.

4: Why do some silicone products have a smell?

It may be caused by HTV not being fully vulcanized or low-cost additives. Regular LSR is odorless.

5: Can silicone be recycled and remade?

Yes, through powderization + filler reuse, but the material properties must be maintained and meet the use standards.

6: Why is the price difference so big?

Because the product focus is different: LSR, HTV, adding functional fillers and testing costs vary greatly.

7: How to deal with silicone waste?

Recycle chlorosilane and incinerate and carbonize, and a small amount of solidified products are directly landfilled or burned to recycle energy.

8: Can the color or hardness be customized in batches?

Common, masterbatch and filler can be adjusted as needed to meet customized needs.

Summary

Silicone production is a high-tech process from high-temperature smelting, distillation and purification to precise formulation and vulcanization molding. Combined with refined management and functional fillers, silicone has a wide range of application value to meet the needs of multiple industries. However, its quality and safety are inseparable from strict production formulas, advanced molding processes and strict quality control. Whether you are concerned about high-end maternal and child health, medical equipment, or industrial applications, a deep understanding of the entire process of “how silicone is produced” is crucial to ensuring product quality, reducing risks and precision marketing. Welcome to contact Z.S.R Group to provide full technical and commercial support for your silicone project!

Z.S.R also have the own mold workshop and mold design engineer, Complete post-processing workshop own Secondary Vulcanization workshop, Laser engraving workshop, pad printing, screen printing, painting workshop, package workshop. All the silicone products cycle under one roof- from designing products & building tooling to launching into full-blown production.

Contact us to create durable, compliant, brand-ready silicone solutions.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.