How are silicone molded products produced? — Unveiling the entire process from raw materials to finished products

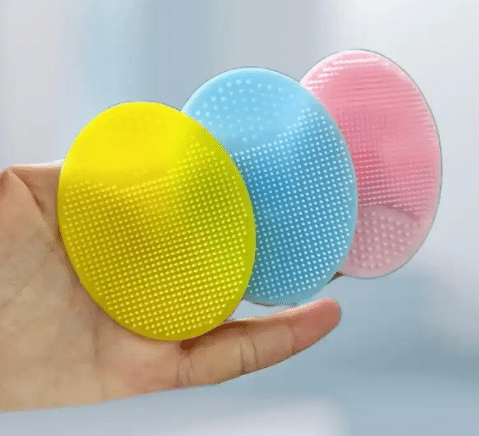

Silicone molded products are ubiquitous in our daily lives: baby pacifiers, heat-resistant kitchen mats, watch bands, automotive parts, medical catheters, industrial accessories, buttons, gifts, bracelets, watches, kitchen utensils, mats, and ice cube trays. These products all rely on a sophisticated molding process. Are you interested in the process of molded silicone products? This article will provide an in-depth analysis of the entire silicone molded product process.

What is molded silicone products?

Molded silicone products are formed by applying pressure to solid silicone raw material containing a vulcanizing agent in a high-temperature mold, resulting in high-temperature vulcanization. Their hardness typically ranges from 30°C to 70°C. The raw material can be colored using color paste, and the mold shape determines the product’s appearance.

Molded silicone is a process whereby the raw rubber is cross-linked and cured within the mold through hot pressing. Its core principles are:

- Material transformation: From linear polysiloxane to a three-dimensional network structure (entropy change principle)

- Precision control: Dimensional tolerances as low as ±0.02mm (required for medical catheters)

- Performance customization: Hardness ranges from Shore A 10-90°, with tear strengths up to 40kN/m.

As a silicone molding factory in China with 16 years, Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(32sets), So Z.S.R have the capability for producing silicone toolings, producing HTV Silicone products, LSR molded silicone products, Molded multi-colored Silicone products. We also can Custom silicone toolings, Custom silicone molding, Custom Silicone compression molding, Custom LSR molding, Custom silicone Dripping injection dispensing (co-injection) , Custom silicone fabric coating and curing molding.

Any Molded silicone project need, please contact Z.S.R.

Why choose silicone molding?

- Initial mold costs are low, and the mold structure is simple, resulting in low maintenance costs. However, with technological advancements, while large silcone molds require a high investment, they offer long-term durability, reducing unit costs in the long term. High-speed presses produce one mold every 45 seconds (80-cavity molds). Compression molding utilizes high-temperature, high-pressure curing for rapid curing, resulting in short production cycles (typically several minutes to tens of minutes), manageable costs, and is suitable for small to medium-volume production. For example, compression molding of silicone rubber products requires only 1-5 seconds to complete the injection molding process, making it 4-7 times more efficient than traditional processes. On August 5, 2025, we just mass-produced a batch of 6,500 silicone parts. Using compression molding, we were able to meet the customer’s part requirements within two days, within budget, after the mass production molds were completed.

- The compression molding process utilizes precision mold control, achieving product dimensional accuracy of ±0.1mm and surface finishes as high as Ra0.1μm, supporting the production of a wide range of shapes and complex structures.

- Wide Material Compatibility: Suitable for thermoset composites (such as glass fiber reinforced materials), rubber, and carbon fiber composites. For example, compression molding of SMC (sheet molding compound) enables the production of complex automotive parts.

- Ample Process Optimization: Material flow characteristics can be optimized by adjusting parameters such as temperature and pressure. For example, in the military industry, orthogonal experiments have been used to determine optimal process parameters, significantly improving the mechanical properties of products. The tensile strength is 30-50% higher than that achieved through infusion.

- Compression molded silicone products offer stable physical properties, high-temperature resistance, aging resistance, and are environmentally friendly and non-toxic.

Z.S.R consists of a strong engineering design team 12 experts with more than 20 years’ experience. We offer personalized services and supports for projects through all steps of products development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly.

Any silicone project, you can contact our expert to get more suggestion.

Who needs silicone molded products?

1. Brand owners seeking OEM/ODM services and outsourcing molds and production. Silicone molded household products are commonly used in kitchenware like silicone ear caps and oven gloves, as well as baby bottle protectors, pacifiers, and bibs. Brand owners and traders seeking food-grade/medical-grade supply chains are looking for these products.

2. E-commerce sellers of maternity and baby products and silicone promotional gifts are seeking differentiated new silicone products (such as collapsible cups and innovative kitchenware).

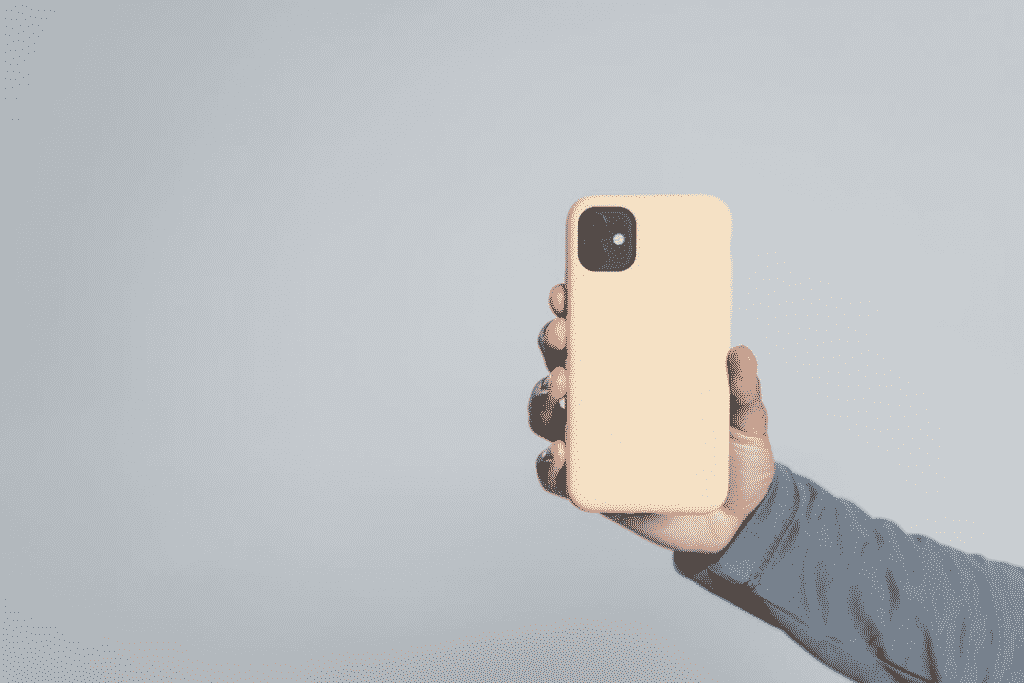

3. Silicone products are often used in shopping mall promotional gifts, electronic accessories (such as silicone buttons), and automotive parts (such as silicone dust covers).

4. In the electronics industry, silicone molded parts are often used in buttons and sealing components of electronic products such as remote controls, keyboards, electronic dictionaries, and toys, providing wear resistance and dustproof functions. In the automotive industry, silicone rubber products are widely used in automobile manufacturing, such as sealing gaskets, spark plug insulation sleeves, tires, etc., with high temperature resistance and chemical corrosion resistance. Industrial customers: Silicone molded parts are used as sealing plugs and insulating sleeves in industrial equipment, etc., and are suitable for high temperature and oil resistant environments, requiring high-performance temperature-resistant seals.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Custom Silicone Products | OEM/ODM Service

Contact Z.S.R to kick off your silicone projects.

When need to choose silicone molding?

New product prototyping you can choice the silicone compression molding, this is low investment, fast trial production in 7-22 days

Small to medium-volume orders, thousands to hundreds of thousands of pieces. If more than 1000.000pcs, we suggest you use the silicone injection molding.

Projects requiring high quality consistency, such as medical and baby products, we suggest you can use the liquid silicone rubber injection molding. If less quantity than 10.000, you can use the compression molding with the Platinum vulcanizing agent.

Z.S.R is a full-service custom silicone products manufacturer offering end-to-end customization, from mold development, prototyping to mass production and packaging. Z.S.R already customized more than 10.500 custom silicone products projects for our partner in the past 16 years with much experience in silicone products technical solution.

Contact Z.S.R to kick off your silicone products project.

Where is the molded silicone product manufactured?

Dongguan/Shenzhen/Ningbo, China: The world’s leading silicone molded product manufacturers are concentrated in China, particularly in the eastern coastal areas of Guangdong, Jiangsu, and Shandong provinces. They have a comprehensive mold and production supply chain. Costs are approximately 40% lower than other supply chains.

Europe, America, and Japan: Germany (tolerance ±0.01mm) and Japan (lifespan 1 million cycles) are primarily focused on medical and high-end applications. Medical-grade production is available in Ireland (FDA-certified cluster) and Singapore (Asia-Pacific medical hub).

How are silicone molded products produced?

Your molded silicone products can be molded by:

(1) Compression Molding

Compression molding is a common silicone product molding process, primarily completed by mold coordination. The mold shape determines the shape of the silicone product. Molded silicone products are typically formed by placing solid silicone raw material with a vulcanizing agent in a high-temperature mold. Pressure is then applied to the mold by a vulcanizer, causing it to solidify at high temperatures. The hardness of molded silicone typically ranges from 30°C to 70°C. This relatively simple manufacturing process is suitable for all silicone products, especially those with complex shapes and high dimensional precision requirements, such as mobile phone keypads and silicone tableware. Its advantages include high dimensional accuracy, excellent surface finish, and high production efficiency. Its disadvantages are high mold costs, making it unsuitable for small-batch production. During the compression molding process, mold accuracy and cleanliness must be ensured to prevent mold deformation or contamination that could affect product quality. Furthermore, parameters such as molding temperature and pressure should be properly controlled to ensure product precision and performance.

(2) Injection Molding

Injection molding is a process that combines liquid silicone and plastic, demanding high quality. Its products exhibit excellent thermal stability, cold resistance, excellent electrical insulation properties, and do not produce toxic substances when burned. They have become an irreplaceable material in the production and design of health products, automotive products, baby products, medical supplies, diving equipment, kitchen utensils, and seals. Injection molding involves separating the silicone raw material into two components, adding each component to an injection molding machine and thoroughly mixing them. The components are then placed in a mold and formed by varying the temperature. This process is suitable for producing high-precision, thin-walled, and complex-structured products and is widely used in the medical and optical fields, such as contact lenses and medical silicone products. During the injection molding process, parameters such as the raw material mixing ratio, temperature, and pressure must be strictly controlled to ensure product quality and performance.

(3) Extrusion Molding

Extrusion molding involves continuously extruding the silicone raw material through a screw extruder through a specifically shaped die to form a continuous profile, such as silicone tubing or sealing strips. Extrusion molding offers high production efficiency and is suitable for producing long products with fixed cross-sectional shapes. During the production process, parameters such as extrusion speed and temperature can be adjusted to control product size and performance. Typically, extruded silicone rubber forms long strips or tubes that can be cut to size, but the shapes of products produced through the extrusion process are relatively simple, mostly in the form of strips. Silicone tubing is commonly used in medical and mechanical equipment. During extrusion, it is important to ensure the proper operation of the extruder and perform regular maintenance and servicing to guarantee product quality and production efficiency.

(4) Calendaring

Calendaring involves kneading silicone rubber with silica, silicone oil, and other materials to create a rubber mix, which is then calendared into sheets. The resulting sheet exhibits significant differences in mechanical properties between the longitudinal and transverse directions, a phenomenon known as the calendaring effect. Specifically, the longitudinal tensile strength is greater than the transverse tensile strength, the transverse elongation is greater than the longitudinal tensile strength, and the longitudinal shrinkage is greater than the transverse tensile strength. The magnitude of the calendaring effect depends on the composition of the rubber compound, the calendaring temperature, the calendaring speed, and the speed ratio. Calendaring is used for larger products, such as silicone sheets and plates. During the calendaring process, parameters such as the calendaring temperature, pressure, and speed must be strictly controlled to ensure the calendaring effect and product quality.

(5) Infusion (Pouring) Molding

Infusion or pouring molding involves surrounding the product or model to be replicated with a plastic or glass plate. Vacuumed silicone is poured directly onto the product. After the silicone dries and forms, the product is removed, and the mold is complete. Infusion molds typically use relatively soft silicone, making demolding easier without damaging the product inside. This process combines solid and liquid materials. This process is often used for relatively smooth or simple products, as the absence of mold lines saves labor and time. Products such as cell phone cases and luggage covers are suitable for this process. During infusion molding, the vacuum level and injection volume of the silicone must be ensured to ensure mold quality and product quality.

(6) Silicone Dripping Molding

In the silicone dripping molding process, the silicone raw material is liquid. The material is placed in a syringe and dripped onto the mold using a combination of pneumatic and manual methods. The material is then heated and vulcanized to form the mold. This process is manual and requires a lot of manual labor, resulting in low production capacity. However, it has a characteristic that a product can be dripped with multiple colors according to requirements, so this process is mostly used to make handicrafts. During the glue dripping molding process, the speed and amount of glue dripping, as well as the heating and vulcanization time and temperature, must be strictly controlled to ensure the quality and appearance of the product.

Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(32sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc.

Contact Z.S.R to kick off your needed silicone products.

What is the production process of silicone products?

1. Raw Material Selection and Pretreatment

The quality of silicone products depends primarily on the raw materials. Manufacturers must select different grades of base silicone rubber (such as food grade, medical grade, or industrial grade) based on the intended use, and then add additives such as colorants, vulcanizers, and plasticizers.

Raw Material Testing: Base silicone properties are verified through hardness and tensile strength tests to ensure compliance with industry standards (such as FDA and LFGB certification).

Pretreatment: Some high-precision products require filtering the base rubber to remove impurities or using a vacuum degasser to remove air bubbles in the rubber to prevent porosity defects in the finished product.

2. Mixing and Color Matching

Thorough mixing of the base rubber and additives is a key step in ensuring product uniformity:

Internal Mixer Mixing: In a closed internal mixer, high-temperature shear forces are used to uniformly blend the rubber, vulcanizer, and colorant. The temperature is typically controlled between 40-60°C to prevent premature curing.

Color Accuracy: Medical or food contact products require the use of inorganic pigments, and color differences are calibrated using a spectrophotometer to ensure color consistency between batches.

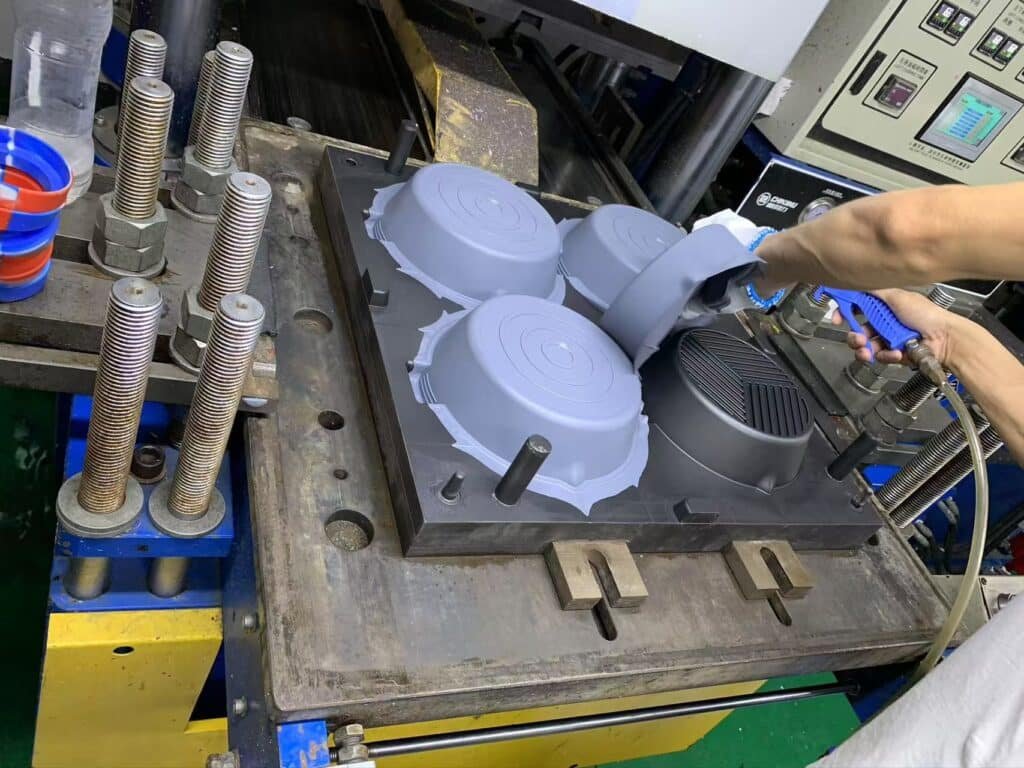

3. Mold Design and Molding

The molding process directly impacts the product’s appearance and dimensional accuracy:

Mold Processing: Based on the 3D design drawings, steel molds are produced using CNC machining or EDM. The precision mold tolerance must be controlled within ±0.02mm.

Molding Method Options:

Compression Molding: The rubber compound is placed in the mold and heated and pressurized using a flat-plate vulcanizer. Suitable for simple seals, buttons, and other products.

Liquid Injection Molding (LSR): Liquid silicone is injected into the mold cavity. Suitable for producing special-shaped parts and thin-walled products (such as nipples and catheters).

Extrusion Molding: A screw extruder is used to continuously produce long strips of silicone tubing, sealing strips, and other products.

4. Vulcanization and Curing

Vulcanization is the core step in cross-linking silicone molecular chains and determines the physical and chemical properties of the product.

Primary Curing: The rubber compound is initially cured by compression molding or heating in a drying oven at a high temperature of 120-180°C. The curing time is adjusted based on the product thickness (usually 5-15 minutes).

Secondary vulcanization: For high-performance products (such as high-temperature resistant gaskets), a secondary baking (200-250°C) is performed to further eliminate volatile substances and improve tear strength.

5. Post-Processing and Surface Modification

Molded silicone products undergo multiple finishing steps:

Deburring: Manual or cryogenic deburring machines are used to remove excess glue at the mold parting line.

Surface Treatment: Sandblasting, laser engraving, or UV printing are used to add texture or logos to the product. Medical catheters require plasma treatment to enhance surface hydrophilicity.

Special Coatings: Some electronic components require antistatic coatings, and kitchenware products can be treated with antibacterial coatings.

6. Quality Inspection and Performance Testing

A rigorous inspection system is the last line of defense for product safety:

Appearance Inspection: Use industrial cameras or manual visual inspection to identify defects such as missing material, stains, and bubbles.

Physical Property Testing: Use a tensile testing machine to test tensile strength (≥8 MPa) and a durometer to measure Shore hardness (typically 20-80A).

Chemical Safety Verification: Food-grade products must pass migration testing (detecting heavy metal and plasticizer residues), and medical silicone must comply with biocompatibility standards (ISO 10993).

7. Sterilization and Packaging

End-of-line processing ensures that products meet the requirements of their intended use:

Sterilization Process: Medical-grade silicone products must be sterilized using ethylene oxide (EO) or gamma irradiation.

Dust-Proof Packaging: Vacuum bags or anti-static film are used in a cleanroom. The outer packaging is labeled with the production batch, expiration date, and storage conditions.

Z.S.R is a full-service custom silicone products manufacturer offering end-to-end customization, from mold development and prototyping to mass production and packaging.

Example for silicone compression molding process

1. Raw Material Preparation: Basic Formula and Precise Ratio

The core raw materials for silicone products include liquid silicone rubber (LSR) or compounded silicone rubber (HTV), supplemented with additives such as vulcanizers, fillers, and masterbatches.

Basic Raw Material Selection:

- Liquid silicone rubber (LSR): Made by mixing components A and B in a 1:1 ratio, it has high fluidity and is suitable for injection molding. It is commonly used in high-precision products such as medical catheters and baby pacifiers.

- Compounded silicone rubber (HTV): Raw rubber, silica, and silicone oil are mixed uniformly in a rubber mixer to form a moldable solid compound. It is suitable for silicone phone cases, seals, and other products.

Additive Ratio:

Curing agents, such as platinum catalysts (LSR) or peroxides (HTV), promote cross-linking and curing of silicone. The dosage must be precisely controlled to avoid incomplete or excessive vulcanization.

Fillers, such as fumed silica, can increase hardness and tensile strength, while talc is used to reduce costs. The ratios should be adjusted according to product requirements.

Masterbatch: Customizable colors are achieved using pigments such as carbon black and red iron oxide. Compatibility with the silicone matrix must be ensured.

Raw Material Processing:

LSR must be mixed under vacuum to prevent air bubbles, while HTV must be allowed to stand for at least 24 hours to eliminate internal stresses. Select solid or liquid silicone based on product requirements. Standard silicone has a hardness range of 30°-70°, while transparent silicone can reach 80°. Next, use a mixer to evenly mix the base silicone rubber with the masterbatch and additives. The temperature on the two-roll mixer should be controlled at ≤40°C to prevent premature vulcanization. Filler dispersion should be ≥98% (nanoscale dispersion).

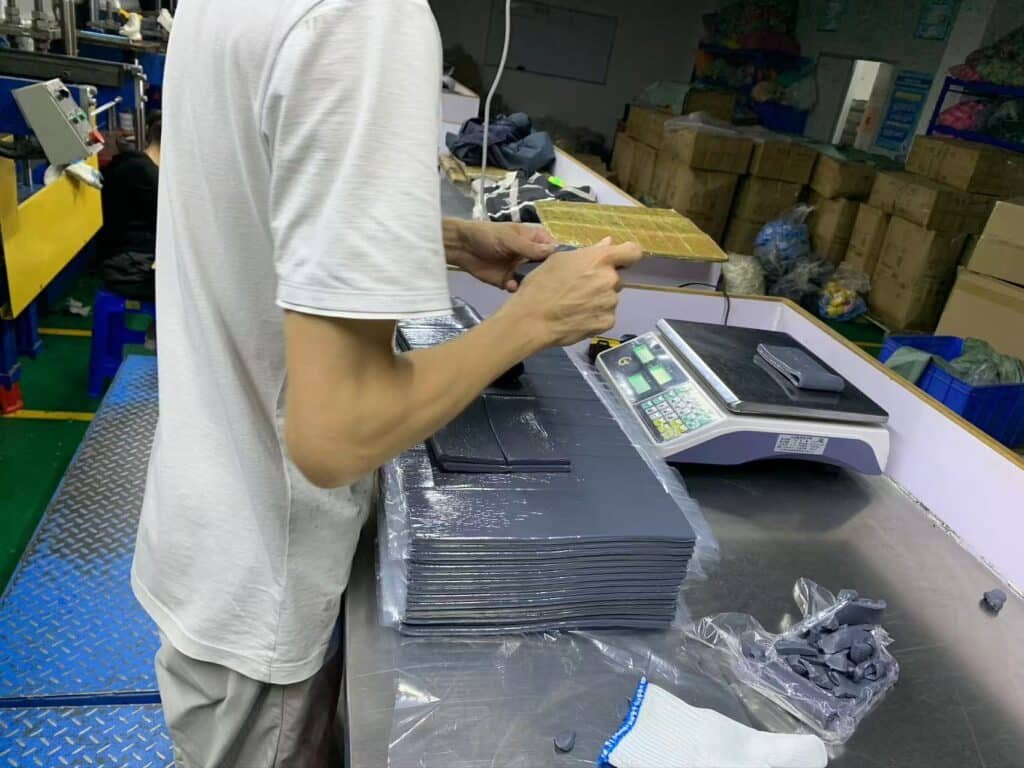

Cutting:

Cut the silicone blank according to the mold cavity size, with a weight tolerance of ±0.5% (±0.1% for precision electronic parts).

Mold Preparation: Design the mold based on the product shape and size, typically made of steel or aluminum alloy. Next, clean the mold and apply a release agent. Medical molds should be preheated to 160-180°C and sprayed with a food-grade release agent (0.5-1.5 mg/cm²).

2. Molding Process: Technical Route and Equipment Selection

Silicone molding processes vary, and the appropriate method must be selected based on the product shape, precision, and production scale.

Compression Molding:

Process: The mixed rubber is placed in a mold and heated and pressurized in a vulcanizer (temperature 150-200°C, pressure 10-20 MPa). The curing time is 5-15 minutes.

Applications: Silicone keypads, seals, etc., suitable for small and medium-sized batch production.

Advantages: High dimensional accuracy (tolerance ±0.1mm), but mold costs are relatively high.

Injection Molding:

Process: The two LSR components are precisely mixed using a metering pump and injected into a preheated mold (temperature 120-180°C). The curing time is 10-60 seconds.

Applications: Medical catheters, baby pacifiers, etc., suitable for high-precision, large-scale production.

Advantages: High degree of automation, increasing production efficiency by over 30%, but equipment investment is relatively large.

Extrusion Molding:

Process: HTV rubber is heated and plasticized in an extruder, then extruded through a die head into a molded shape (such as a silicone tube or strip). It is then cut after cooling.

Applications: Medical catheters, cable sheathing, etc., suitable for continuous production.

Advantages: High production efficiency, but the product shape is monotonous and dimensional accuracy is low.

Drop-coating Process:

Process: LSR is dripped onto the mold surface and cured at a constant temperature (60-120°C, 1-4 hours) to form a thin layer or complex structure.

Applications: Decorative parts for mobile phone cases, electronic buttons, suitable for small-batch customization.

Advantages: Multi-color and multi-material composites are possible, but efficiency is relatively low.

4. This is the Compression Molding:

Place silicone into a mold, heat (170-200°C), and pressurize (515 MPa) to form.

5. Vulcanization

Heat to 170±2°C in a vulcanizer. Hold pressure for a time calculated based on product thickness (e.g., 7.5 minutes for a 5mm thickness). Ensure complete cross-linking.

6. Demolding and Cooling

Medical products must be removed using a suction cup robot and immediately placed in a cooling fixture for final shaping.

7. Deburring

Manual trimming or freeze-drying (-80°C for 2 hours).

Post-Processing and Testing: Quality Assurance and Performance Optimization

After molding, silicone products undergo trimming, curing, and testing to ensure they meet standards.

Trimming and Cleaning:

Burnt at the parting line is removed manually or by a punch, and ultrasonic cleaning is used to remove oil and impurities.

8. post-vulcanization (required for food and medical grades)

Removes residual small molecules and improves safety. Some products require a post-curing oven cure (180-200°C, 2-4 hours) to reduce residual volatile matter and improve aging resistance.

Performance Testing:

Physical Properties: Hardness (Shore A/D), tensile strength, tear strength, resilience, etc.

Chemical Properties: Acid, alkali, oil, and solvent resistance tests.

Biocompatibility: Medical-grade silicone must pass ISO 10993 biosafety certification.

8. Inspection and Packaging

Full inspection items: Dimensional Cpk ≥ 1.33, hardness ± 2°, tear strength.Inspect for defects such as bubbles, missing material, and color variations to ensure surface finish.

Quality rate benchmark: Medical grade ≥ 99.5%, industrial grade ≥ 98.2%

Please go through the How to make silicone products and how to put the logo on silicone products to know more details

Contact Z.S.R if you need the custom silicone molding service.

What is the silicone molding cost?

Key factors:

- Number of mold cavities

- Silicone formula

- Labor costs

- Production volume

How to choose the right supplier for molded silicone products?

First, consider technical capabilities:

Depending on the product’s intended use, whether it’s food-grade, industrial, or medical. If it’s medical-grade, check whether the supplier has ISO 13485 medical certification.

The supplier’s maximum press tonnage determines product size and quantity, which in turn determines delivery stability. A suitable supplier can ensure product consistency and delivery stability.

Check mold accuracy (tolerance ±0.05mm for high-end medical grade).

Second, consider the quality system:

SPC statistical process control implementation level, ISO9001 application documentation completeness,

Laboratory testing equipment integrity

Third, Cost control:

Raw material procurement channels

Four, response speed:

Mold manufacturing cycle: Standard time is 45 days.

Ability to handle urgent orders: During the Bing Dwen Dwen shortage in 2022, Z.S.R. leveraged its massive production capacity and ability to mobilize industry resources to produce 500,000 25cm silicone casings within two months.

How do we control the quality of silicone products?

IQC (Integrated Quality Control) raw material inspection ensures that each batch of silicone raw materials passes RoHS and REACH testing, and also tests hardness and inspects appearance.

IPQC (In-Process Quality Control) process control: IPQC conducts random product inspections and ensures temperature accuracy during production: ±1°C (±0.5°C for medical applications) and pressure stability: ±2%.

(1) Dimensional Accuracy Control

The dimensional accuracy of silicone products directly impacts their performance and assembly quality. During the molding process, mold dimensional accuracy and molding parameters, such as temperature, pressure, and time, must be strictly controlled. For compression molding, different molding parameters must be set according to the structure of the silicone product. This requires professional skills and adherence to standardized operating instructions. Regular mold maintenance and servicing are also necessary to ensure stable dimensional accuracy. For extrusion molding, parameters such as extrusion speed and temperature must be adjusted to control product dimensions.

(2) Appearance Quality Inspection

Appearance quality is the first impression of silicone products and is a key indicator of product quality. After molding, the product must undergo a rigorous appearance quality inspection, including inspection for surface defects such as bubbles, cracks, impurities, and burrs. For compression-molded and injection-molded products, special attention should be paid to the parting line to ensure a smooth and even surface. For extrusion-molded products, the cross-sectional shape and surface quality should be inspected. For calendered products, the film thickness uniformity and surface flatness should be checked.

(3) Physical and Chemical Property Testing

The physical and chemical properties of silicone products are directly related to their performance and safety. During the production process, products must undergo various physical and chemical property tests and inspections, such as hardness, tensile strength, tear strength, aging resistance, and chemical corrosion resistance. A comprehensive quality management system must be established, with strict control over every step, from raw material procurement to finished product delivery. Furthermore, inspection and testing equipment should be regularly calibrated and maintained to ensure the accuracy and reliability of test results.

Degree of vulcanization: A torque rheometer monitors T90 time.

FQC (Finished Product Quality Control) involves testing the appearance, dimensions, performance, and chemical properties of silicone molded products. This ensures that every batch shipped is tested and inspected.

Silicone steel molds must also undergo regular maintenance, with a comprehensive inspection every 5,000 molds.

Material traceability: Batch management and laser marking ensure tracking of silicone molded products, with each batch containing a unique tracking code.

Z.S.R understand the importance of quality, our whole-process quality control system ensures that our customers can receive the qualified products as they approved before mass production.

Z.S.R Group’s quality ratings are sustained through the implementation of a rigorous quality control system. All the products quality is carefully verified through in-process inspection plans where products are constantly monitored for defects, damage, or any other inconsistencies. Every product package can then be traced back to the date the part was produced, the processes performed, and the materials employed.

Contact Z.S.R to create your molded silicone products.

How to Clean Silicone Products?

More FAQs

Summary

The lifespan of steel molds is 300,000 to 500,000 cycles, depending on proper maintenance.

Silicone molded product production is a relatively mature, flexible, and economical manufacturing process that can meet diverse needs across a wide range of applications, including infant, medical, food, and industrial applications. Customers place high demands on safety, precision, and on-time delivery, and Z.S.R.’s solutions are precisely tailored to build trust and foster partnerships.

Silicone molded products, while seemingly simple, embody the art of high-precision craftsmanship and quality control. Z.S.R are the partner choice of custom silicone products for leading silicone products brands and retailers. Recognized for delivering innovative molded silicone products, silicone products manufacturing expertise, and silicone technical solutions to meet your brand’s functional and design needs.

Contact Z.S.R to create durable, compliant, brand-ready silicone products solutions.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.