TPR vs. Silicone: A Material Comparison to Understand the Differences in One Article!

TPE, TPR (collectively, thermoplastic rubber), and silicone—two elastic materials—are widely used in consumer electronics, automotive parts, kitchenware, medical care, and other fields. However, there are significant differences between the two in terms of thermal stability, processing, recycling performance, and safety. Precisely selecting materials based on application scenarios is crucial for designers and buyers. This article provides an in-depth analysis of definitions, properties, and more to help you make informed decisions quickly.

What is TPR/TPE?

Thermoplastic elastomer (TPE or TPR) is a polymer material that combines the elasticity of rubber and the processing properties of thermoplastic plastics. It exhibits high elasticity of rubber at room temperature and can be plasticized and molded at high temperatures.

What is silicone?

Thermoplastic elastomers (TPE or TPR) are a class of polymer materials that lie between rubber and plastic. Their core properties include:

- Room-temperature elasticity: They possess high elasticity and flexibility similar to vulcanized rubber.

- High-temperature plasticity: They can be melted and reshaped upon heating, allowing them to be formed through thermoplastic processing methods such as injection molding and extrusion.

Structural Characteristics

The molecular structure of TPE typically consists of hard and soft segments, either in blocks or grafted together:

- Hard segments: Provide strength through physical crosslinking (such as hydrogen bonds and crystalline regions) and reversibly dissociate at high temperatures.

- Soft segments: Embody high elasticity and flexibility, such as polybutadiene segments.

Thermoplastic elastomers combine the injection moldability of plastics with the elasticity of rubber, allowing for melt reprocessing and recycling.

Silicone: A thermosetting silicone elastomer with a stable structure, high temperature resistance, and inability to melt.

Silicone is a highly active adsorption material primarily composed of silicon dioxide. It is an amorphous substance with the chemical formula mSiO₂·nH₂O. Its core properties include:

- Chemical Composition

- The main component is silicon dioxide (SiO₂), which is insoluble in water and common solvents. It is chemically stable and reacts only in strong bases or hydrofluoric acid.

- Physical Properties

- Structure: Amorphous with a porous microstructure, classified by pore size into macropores, coarse pores, and fine pores. The adsorption performance varies significantly depending on the pore size.

- Stability: High temperature resistance (typically above 300°C) and high mechanical strength make it suitable for industrial catalyst supports, desiccants, and other applications.

Who cares about the difference between Thermoplastic Elastomer and Silicone?

When should I use a thermoplastic elastomer (TPE) or silicone?

High-temperature applications, such as baking, seals, and automotive parts, require high-temperature resistance, so silicone is not the right material. Silicone (-40 to 230°C) outperforms most TPE materials (typically -50 to 150°C).

Chemical Resistance: Silicone is more stable against chemicals, while TPE is more resistant to oils and solvents.

Environmental Performance: Both are non-toxic, but silicone, containing silicon dioxide, is more environmentally friendly, while TPE is more recyclable. For medical/food-grade applications, silicone is a must.

Electronic accessories (phone cases, smart wearables): TPE offers lower costs, faster molding, and higher yields. Packaging and casings are recyclable.

Thermoplastic elastomers (TPE/TPU, etc.) can be quickly formed directly through injection molding or extrusion without vulcanization, resulting in high processing efficiency and support for waste recycling.

Silicone requires compression molding or injection molding, which requires a vulcanization process, resulting in longer processing cycles and difficult waste recycling.

For complex designs requiring high-precision injection molding, TPR is preferred. For medical products, liquid silicone injection molding is an option.

Z.S.R support our partner silicone products from idea to market.

Where you can use the Thermoplastic Elastomer or Silicone ?

Thermoplastic elastomers (TPEs) have a wide range of applications, primarily covering the following scenarios:

Automotive Industry

Used in seals, shock absorbers, interior trim, wiring harnesses, and new energy vehicle battery pack sealing materials, they offer lightweight properties (20%-30% lighter than traditional rubber), oil resistance, and recyclability.

Healthcare

Used in medical catheters, respiratory masks, soft-touch components of wearable devices, and latex-free gloves, TPE materials offer high transparency, hypoallergenic properties, and meet FDA/EU certification.

Consumer Electronics

Used in:

- Smartwatch straps

- Soft-touch components of earphones

- Drop-resistant mobile phone cases

The materials are sweat-resistant and highly resilient.

Construction

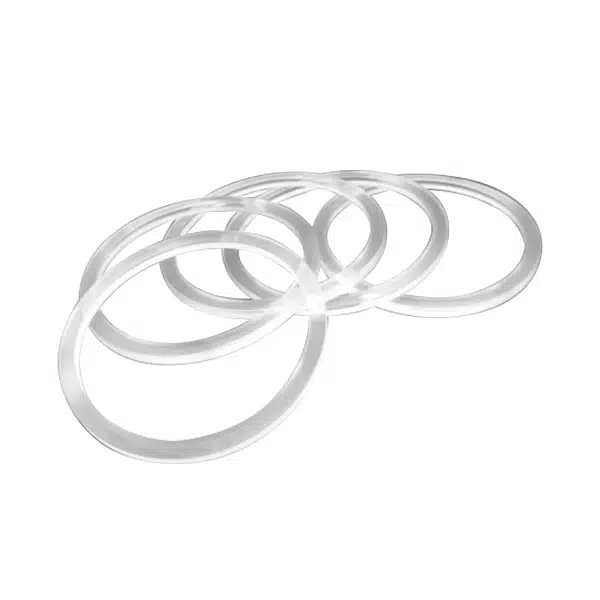

Used in energy-saving door and window seals, roof waterproofing membranes, and seismic-resistant pipe connectors, these environmentally friendly building materials meet green building standards.

Packaging and daily necessities

Food-grade soft bottle cap gaskets, eco-friendly straws, and toothbrush handles are PVC alternatives.

Industrial manufacturing

These include flexible robot grippers, wear-resistant coatings for conveyor belts, and reinforcements for hydraulic hoses. High-temperature-resistant TPE (continuous operating temperature 150°C+) can replace fluororubber.

Silicone has a wide range of applications, primarily covering the following scenarios:

Healthcare

Medical devices, implantable and non-implantable devices such as artificial joints and respiratory masks, as well as maternal and infant products such as pacifiers and silicone suction cups.

Consumer Electronics

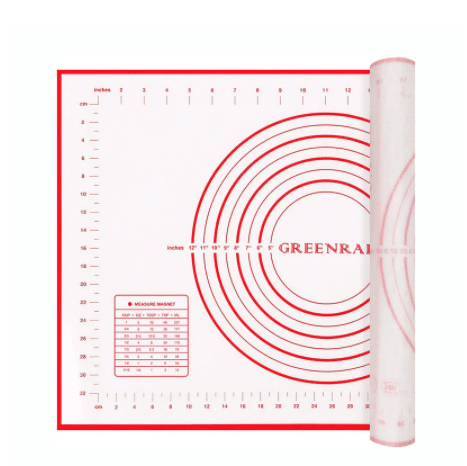

Including waterproof seals for smartwatches, in-ear earbuds, and baking molds (resistant to 230°C).

Industrial Manufacturing

Used in automotive engine seals and gaskets, photovoltaic module encapsulation materials, and aviation applications.

Life Scenarios

Used in kitchen utensils, high-temperature cookware (such as stirring spoons, potholders, and teapot holders), personal care tools (face brushes and cleansing devices), and outdoor equipment (water bottles and backpacks).

How to choose the right material between Thermoplastic Elastomer and Silicone?

Silicone has better high-temperature resistance, typically ranging from -40°C to 230°C, with some special formulas capable of withstanding even higher temperatures. TPE has a narrower temperature range (approximately -50°C to 100°C), though it can reach 150°C for short periods. However, long-term high temperatures can easily lead to performance degradation. If the product is intended for use at temperatures >120°C, silicone is recommended.

You can confidently place Z.S.R’s custom silicone products in extreme environments.

TPR is easy to process (injection molding, extrusion, etc.) and offers low costs. Considering processing costs and efficiency: For large production quantities, consider TPR.

For small-volume customizations requiring extreme performance, choose silicone.

For food and medical products, silicone is easier to obtain certifications.

The first version of the product can be tested for thermal cycling, chemical resistance, and compression rebound. Generally, silicone exhibits superior wear and aging resistance, making it suitable for applications requiring high durability, such as seals and pipes. TPE offers better wear resistance, but may wear or deform over time.

What are the prices and costs of thermoplastic elastomers (TPE) and silicone?

The price and cost differences between thermoplastic elastomers (TPE) and silicone are mainly reflected in material properties and application scenarios.

- TPR/TPE: Relatively low raw material prices and ease of processing result in lower production costs, making them suitable for processes like injection molding and extrusion, resulting in faster processing times and better cost performance for large quantities.

- Silicone: Generally more expensive than TPE, with the specific difference depending on the product type. Silicone is more difficult to process and cures slowly, resulting in higher production costs and requiring significant mold investment, but it can add value to the product. For example, silicone valves are generally more expensive than TPE valves due to higher material costs.

- Medical/food-grade silicone: Silicone is more suitable for applications requiring high material stability, such as medical and food packaging. While its overall cost is higher, it meets high-end positioning and safety requirements.

- Long-term cost: Silicone offers superior heat and chemical resistance, making it stable in high-temperature or corrosive environments. However, the initial purchase cost is higher. TPE is more suitable for general use and has lower maintenance costs.

How to produce thermoplastic elastomers (TPE) and silicone?

TPR/TPE Production Methods

- Process Type: Injection molding, extrusion, blow molding;

- Mold Material: Commonly used steels such as S136 and H13;

- Equipment: Hot runner injection molding machine (standard injection molding machine);

- Molding Characteristics: Can be melted repeatedly, suitable for two-color co-injection and overmolding;

- Production Speed: Fast cycle time, suitable for high-volume automation;

- Adhesion: Can be co-molded with ABS/PC/PP/PE;

- Typical Products: Toothbrush handles, tool grips, and non-slip mats.

Silicone Production Methods

- Solid Silicone: Compression Molding;

- Liquid Silicone (LSR): Liquid Injection Molding;

- Multi-Color Silicone Products: Silicone Dripping Molding;

- Mold Requirements: High precision, good air venting, and mold heating required;

- Production Speed: Solid Silicone molding is slow, while LSR is fast but the equipment is expensive;

- Typical Products: Pacifiers, kitchen molds, medical accessories, and button covers.

How to control the quality of thermoplastic elastomers (TPE) and silicone?

How to clean thermoplastic elastomers (TPE) and silicone?

TPR/TPE can be rinsed with clean water or wiped with alcohol. Avoid using hot water, strong acids or bases, or washing in a machine.

Silicone can be sterilized by boiling, dishwasher, or using a neutral detergent. Avoid scratching with steel wool or strong alkaline solutions that can corrode the color layer.

More FAQs

Summary

- TPE/TPR: Suitable for low-temperature, low-cost, and environmentally friendly recycling projects, with high injection molding efficiency.

- Silicone: Suitable for high-temperature, medical, and food safety applications, offering excellent performance but higher costs.

The key is to choose based on operating temperature, environmental requirements, certification standards, and brand positioning. The two complement each other and are suitable for different market strategies.

For product material optimization and certification support, please feel free to contact Z.S.R Our professional engineering team is dedicated to serving you!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.