Why is silicone so expensive?

The price of silicone products is influenced by three key factors: raw materials, production process, and certification. Different silicone materials, production processes, and certification standards significantly impact the selling price. Silicone has long been considered a high-performance material in the emerging materials sector. It is widely used in medical, baby products, automotive, electronics, kitchenware, seals, and other fields, and is highly sought after for its excellent high- and low-temperature resistance, biocompatibility, flexibility, and safety. However, many customers, brands, and even end consumers have raised the question: Why are silicone products typically more expensive than other rubbers and plastics?

This article will delve into the logic behind silicone pricing and provide marketing and product strategy recommendations for brands and manufacturers.

What is silicone rubber?

Silicone rubber refers to a rubber whose backbone consists of alternating silicon and oxygen atoms, typically with two organic groups attached to the silicon atoms. Ordinary silicone rubber is primarily composed of methyl-containing siloxy groups and a small amount of vinyl groups. The introduction of phenyl groups can improve silicone rubber’s high- and low-temperature resistance, while the addition of trifluoropropyl and cyano groups can enhance its heat and oil resistance. Silicone rubber exhibits excellent low-temperature resistance and can typically function at temperatures as low as -55°C. The introduction of phenyl groups allows for low-temperature resistance down to -73°C. Silicone rubber also exhibits excellent heat resistance, capable of long-term operation at 180°C and maintaining flexibility for weeks or longer at temperatures slightly above 200°C. It can also withstand transient high temperatures exceeding 300°C. Silicone rubber also exhibits excellent breathability, with the highest oxygen transmission rate among synthetic polymers. Furthermore, its physiological inertness and non-setting properties have led to its widespread use in the medical field.

Silicone rubber is categorized into heat-vulcanized silicone rubber (HTV) and room-temperature vulcanized silicone rubber (RTV). RTV silicone rubber is further divided into condensation-polymerized and addition-polymerized types. High-temperature silicone rubber is primarily used in the manufacture of various silicone rubber products, while room-temperature silicone rubber is primarily used as adhesives, potting materials, or molds. Heat-vulcanized silicone rubber is the most widely used type and is further divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, the most widely used and widely available brand), and methyl vinyl phenyl silicone rubber (PVMQ) (which is resistant to low temperatures and radiation). Other types include nitrile silicone rubber and fluorosilicone rubber. Common forms include liquid silicone rubber (LSR) and solid forms: high-temperature vulcanized silicone rubber (HTV) and room-temperature vulcanized silicone rubber (RTV). It combines the elasticity of rubber with the processability of plastic and is widely used in:

- Medical devices, including catheters and seals.

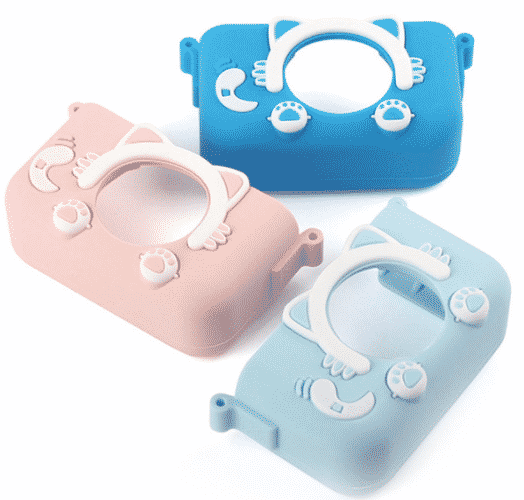

- Baby products, including pacifiers, teethers, bowls, and plates.

- Kitchen utensils, including baking molds, sealing lids, spatulas, spoons, and potholders.

- In the automotive industry, it includes seals and connectors.

- Consumer electronics, including phone cases and wearable accessories.

Z.S.R’s Own Precision Silicone mold /tooling shop ,Silicone Compression molding(48sets)shop, Silicone over-molding, Liquid Silicone Rubber Injection molding shop: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding shop, these capabilities allow Z.S.R to manufacture any type silicone rubber products for our partner’s company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc.

Custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality silicone products for different industry application from industrial, consumer, commercial to medical.

Contact Z.S.R to create durable, compliant, brand-ready silicone products solutions.

Custom Silicone Products | OEM/ODM Service

Why is silicone expensive?

The price of silicone products is influenced by three key factors: raw materials, production process, and certification. Different silicone materials, production processes, and certification standards significantly impact the selling price.

Who cares about silicone prices?

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Contact Z.S.R if you are brands owner or buyer for silicone products.

Custom Silicone Products | OEM/ODM Service

When is silicone price a particularly significant issue?

- Raw material price increases (e.g., the global silicone shortage during the pandemic caused prices to double)

- New product development phase: Samples molds and small-batch trial production are expensive, resulting in higher unit prices after amortization)

- Compared with alternative materials (e.g., silicone appears more expensive when compared to TPE, rubber, and PP plastic)

Where markets are most concerned about price?

Developing countries: They are cost-sensitive and often question price.

European and American markets: While highly receptive, they also seek “value for money” and will discuss the reasons for high prices in reviews.

How is silicone produced?

First step: Raw Material Synthesis

The key to silica gel production lies in the conversion of raw materials. The main raw materials include silane compounds such as dimethyldichlorosilane and silicon tetrachloride, which undergo hydrolysis and condensation reactions to form polysiloxanes. This step is the foundation of silica gel production and directly determines the performance and quality of subsequent products.

During the hydrolysis and condensation process, dimethyldichlorosilane ((CH₃)₂SiCl₂) first undergoes hydrolysis in water to form a silane-oxygen (Si-O-Si) polymer. The specific reaction formula is:

(CH₃)₂SiCl₂ + H₂O → (CH₃)₂Si(OH)₂ + HCl

Subsequently, the hydroxyl groups (Si-OH) in these products undergo further condensation to form linear or network-structured polysiloxanes. The reaction equation is:

(CH₃)₂Si(OH)₂ + (CH₃)₂Si(OH)₂ → (CH₃)₂Si-O-Si(CH₃)₂ + H₂O

This series of reactions constitutes the core chemical process of silica gel production. Hydrolysis and condensation reactions are the foundation of silica gel production.

Mixing Process: Adding a vulcanizing agent and masterbatch, then processing in an internal mixer. To further enhance the performance of silicone, various additives are added. These include reinforcing agents, such as silica (fumed silica), which increases the strength and improves abrasion resistance. Catalysts, such as peroxides (for addition-type silicones) or platinum catalysts (for condensation-type silicones), are also essential to accelerate the curing reaction. Crosslinkers, meanwhile, further increase the crosslink density of the molecular chains, thereby improving the stability of the silicone. Of course, other additives, such as anti-aging agents, colorants, and flame retardants, can also be added as needed. Additives enhance the performance of silicone and are uniformly mixed in an internal mixer or kneader.

Raw Materials and Mixing Equipment

In silicone production, reactors, storage tanks, and mixing equipment such as kneaders or two-roll mills are essential. Equipment such as reactors and storage tanks are key facilities for storage and chemical reactions.

Reactors are core equipment in silicone production, primarily used for the synthesis of siloxane bases, such as hydrolysis and condensation reactions. Storage tanks are used to store key raw materials such as dimethyldichlorosilane, catalysts, and silica.

Molding and Vulcanization Equipment

Extruders, injection molding machines, and vulcanization equipment are key equipment in the silicone molding and vulcanization process. Production lines based on extruders and injection molding machines complete the shaping of silicone.

Extruders are primarily used to produce continuous products such as silicone strips and tubes. Injection molding machines are particularly suitable for the production of liquid silicone rubber (LSR) products. Hot vulcanizers and heating furnaces ensure a smooth vulcanization process for silicone products.

Auxiliary Equipment

Auxiliary equipment includes air purification systems, exhaust gas treatment equipment, and various testing equipment to support production. Environmental protection and product quality monitoring equipment support production.

An air purification system ensures a cleanroom environment for producing medical-grade silicone. Testing equipment includes hardness testers, tensile strength testers, and elongation testers.

Molding processes

1. Compression Molding

Compression molding is the most common manufacturing process. It primarily involves molds, with the mold’s shape determining the silicone product’s shape. Molded silicone products are typically formed by placing solid silicone raw material with a vulcanizing agent in a high-temperature mold. Pressure is then applied to the mold using a vulcanizing machine, where it solidifies. The hardness of molded silicone typically ranges from 30° to 80°. This manufacturing process is relatively simple and suitable for all silicone products.

2. Injection Molding

This process requires relatively high quality and combines liquid silicone with plastic.

The resulting products exhibit excellent thermal stability, cold resistance, and electrical insulation properties, and do not produce toxic substances when burned.

This makes it an indispensable material in the production and design of health products, automotive products, baby products, medical supplies, diving equipment, kitchen utensils, and seals.

3. Extrusion Molding

Extrusion molding involves extruding silicone products using an extruder. Extruded silicone products are typically formed into long strips, and tubular shapes can be cut to size. Products produced through the extrusion process typically have a relatively simple shape, mostly in the form of strips. Silicone tubing is widely used in medical and mechanical equipment. It can also serve as a buffer in packaging materials.

4. Calendaring

Silicone rubber is kneaded and mixed with silica, silicone oil, and other ingredients to create a rubber mix, which is then calendered into sheets.

The sheets produced by calendering exhibit significant differences in their mechanical properties in the longitudinal and transverse directions, a phenomenon known as the calendering effect. Specifically, the longitudinal tensile strength is greater than the transverse tensile strength, the transverse elongation is greater than the longitudinal tensile strength, and the longitudinal shrinkage is greater than the transverse tensile strength.

The calendering effect results from the orientation of macromolecules and needle- and flake-shaped additives in the rubber compound along the calendering direction during the calendering process. The magnitude of the calendering effect depends on the composition of the rubber compound, calendering temperature, calendering speed, and speed ratio.

This is used for larger products, such as silicone sheets and plates.

5. Infusion Molding

Infusion molding or pouring molding: It’s used for relatively smooth or simple products. The lack of mold lines saves time and effort. The product or model you want to replicate is surrounded by plastic sheets or glass plates. Vacuum-evacuated silicone is poured directly onto the product. After the silicone dries and forms, the product is removed, and the mold is complete. (Note: Infusion molds are generally made with softer silicone, making demolding easier and preventing damage to the product inside.) This method combines solid and liquid materials and is used in products such as phone cases.

6. Coating Molding

Fast vulcanization; strong adhesion; good flowability; and easy degassing. Using a platinum complex catalyst, it’s non-toxic and odorless. It offers excellent thermal stability and cold resistance (operating temperature -60°C to 200°C). The molded product exhibits good air permeability, heat resistance, and a certain degree of tensile strength, as well as excellent anti-slip properties.

Non-polluting; low hardness; strong adhesive bonding; high tear strength; high transparency; and good tensile properties. It’s abrasion-resistant, washable, and heat-resistant. It boasts a high three-dimensional texture, a smooth, soft, and flexible texture, excellent elasticity, and is washable and dry-cleanable.

It has an anti-aging effect when applied to fabrics, such as silicone gloves and rain boots.

Z.S.R’s consists of a strong engineering design team 12 experts with more than 20 years’ experience. We offer personalized services and supports for projects through all steps of products development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly.

Contact our expert to offer the professional silicone molding suggestion.

Post-Vulcanization

After molding, silicone requires vulcanization to impart the necessary elasticity and strength. Vulcanization imparts elasticity and strength to silicone using two primary methods:

- Hot vulcanization: The silicone is placed in a mold and heated to a temperature between 150°C and 200°C to cure.

- Room Temperature Vulcanization (RTV): Some types of silicone cure naturally at room temperature through a chemical reaction.

Post-Processing and Packaging

Depending on the intended use of the silicone product, additional post-processing steps may be required. These steps include:

- Post-Vulcanization: The product is heated again to approximately 200°C to remove residual volatiles produced during the vulcanization process and further enhance its physical properties.

- Surface Treatment: The product can be sprayed, polished, or laser-marked to enhance its appearance or add specific features.

- Quality Testing: The product is tested for performance indicators such as hardness, tensile strength, and elongation to ensure it meets the expected quality standards.

The product is cleaned and dried before quality testing and packaging to ensure environmental and safety.

After a series of production steps, silicone products need to be cleaned, dried and quality tested, then packaged according to established specifications and finally shipped to customers.

What does the cost of silicone products breakdown?

How to choose a silicone product?

Choosing a silicone product depends on the specific use case and needs, primarily considering factors such as material properties, safety, durability, and cleanliness and maintenance:

Material Selection

- Medical-grade silicone:

- Suitable for medical assistive devices (such as pillows and protective gear). Must be certified by medical standards such as ISO 10993 and offer superior biocompatibility and antibacterial properties.

- Food-grade silicone:

- Used in food-contact applications such as tableware and kitchenware. Must comply with international standards such as FDA and LFGB.

- Ordinary silicone:

- Suitable for general industrial products. Lower cost, but not suitable for direct contact with food or the human body.

Safety

Prefer products with national certifications (such as the QS mark) to ensure they are non-toxic and harmless.

Avoid products with overly bright colors or pungent odors, as they may contain excessive pigments or chemical additives.

Special Scenarios

Infant and toddler products:

Choose medical-grade silicone with safety certifications.

Household items:

Focus on breathability and comfort, choosing high-density sponge or silicone with air pores.

Durability

Silicone is highly resistant to aging, with a normal lifespan of over five years; sponges have a lifespan of approximately two to three years.

Regularly inspect the product and replace it if the silicone becomes hard or discolored, the sponge collapses, or develops an odor.

How to control the cost of silicone products?

Cost control for silicone products requires optimization across multiple dimensions, including raw materials, processes, equipment, and management. Specific measures are as follows:

Raw Material Cost Control

- Supply Chain Management: Establish long-term partnerships and prioritize cost-effective suppliers. For example, reduce procurement costs through centralized purchasing.

- Material Optimization: Select appropriate materials (such as food-grade silicone and specialty silicone) based on product requirements, reduce the use of functional additives (such as flame retardants and colorants), and minimize raw material loss (limited to 5%-15%).

- Procurement Strategy: Avoid peak raw material price periods and schedule procurement wisely to reduce costs.

- Select silicone raw materials of appropriate grades (the highest standards are not necessary for non-medical grade products).

Process and Equipment Optimization

- Process Improvement:

- Liquid silicone products utilize staged and secondary vulcanization processes to reduce internal stress and extend product life.

- Optimize mold design to reduce flash and waste. Maintain mold accuracy within ±0.01mm to minimize burr loss. Also, maximize batch production to spread mold costs.

- Equipment Upgrade:

- Introduce automated equipment (such as injection molding machines and degassing devices) to increase automation (e.g., automated liquid silicone injection molding) and reduce reliance on manual labor.

- Perform regular equipment maintenance to avoid production downtime losses.

- Cost Control Strategies:

- Mold Development Cost Control:

- Prioritize flat vulcanization molds (costing approximately 3,000-10,000 RMB). After confirming the market, upgrade to liquid injection molds (costing 50,000-80,000 RMB).

- Molds with complex structures can be invested in phases, starting with trial production before mass production.

- Hidden Loss Management:

- Reduce the consumption of auxiliary materials such as release agents and white spirits, and reduce losses through engineering mold trials.

- Introduce compression set testing and airtightness testing to identify quality issues early.

- Mold Development Cost Control:

Management Optimization

- Budget Planning:

- Develop an annual budget plan and adjust it dynamically to respond to market changes.

- Risk Reserve:

- Reserve a 10%-30% risk fund when quoting to cover design or process changes.

- Household silicone cookware: Wash with warm water, avoiding strong acids or alkalis.

- Medical silicone: Sterilize with high-temperature steam or wipe with alcohol.

- Industrial silicone components: Regularly inspect for aging and avoid oil and corrosion.

How to clean and maintain silicone?

Silicone has a smooth surface and can be sterilized with boiling water, making it less susceptible to bacterial growth. For household silicone cookware, wash with warm water, avoiding strong acids and alkalis. Medical silicone products should be sterilized with high-temperature steam or wiped with alcohol.

Industrial silicone parts should be regularly inspected for aging and to avoid oil and corrosion.

More FAQs

Summary

Silicone’s high price isn’t just due to high material and production costs, but also stems from its inherent safety, environmental friendliness, and durability. For both brands and consumers, understanding the logic of “high short-term price, long-term value” is key to embracing silicone’s value.

In this way, silicone’s “high price” can be transformed into “high value,” becoming a core competitive advantage for brands.

Z.S.R is a full-service custom silicone products manufacturer offering end-to-end customization, from mold development, prototyping to mass production and packaging for our business partners. Z.S.R already complete more than 10.500 custom silicone products projects in the past 16 years with much experience in silicone products technical solution

Contact Z.S.R to kick off your silicone products now!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.