How to Put Logo or Pattern on Silicone Sleeves?

Silicone has exceptional durability when compared to some other materials, such as hard plastic. It will not crack or chip off any parts of it if it falls or is impacted. It will also be easily cleaned if it has gotten a bit dirty over time. Silicone sleeves are versatile and useful in many different applications in our daily life. They provide protection, insulation, and a non-slip grip, making them a practical choice for many people and industries.

What is silicone sleeves and what is the use of silicone sleeves?

Standard silicone sleeves are made in either a seamless silicone rubber tube, or from a silicone sheet material which is formed into a silicone sleeve or a silicone flexible. Silicone rubber is a semi-organic synthetic made from sand and alkyl or aryl halides.

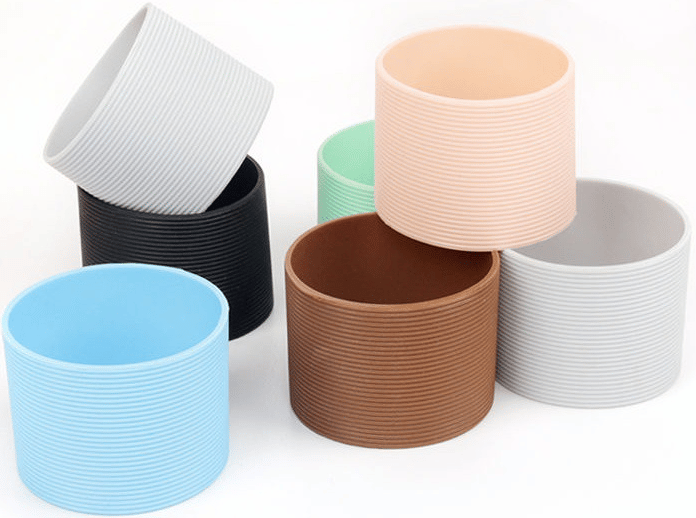

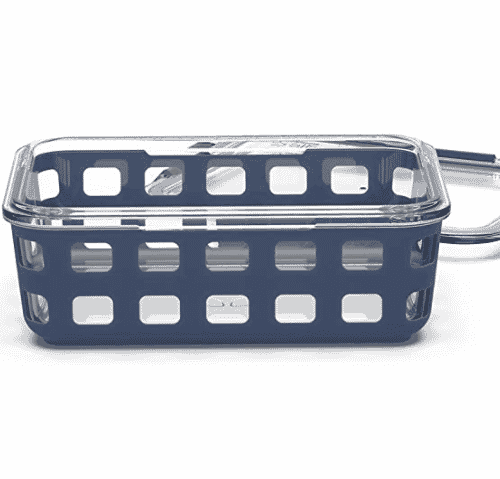

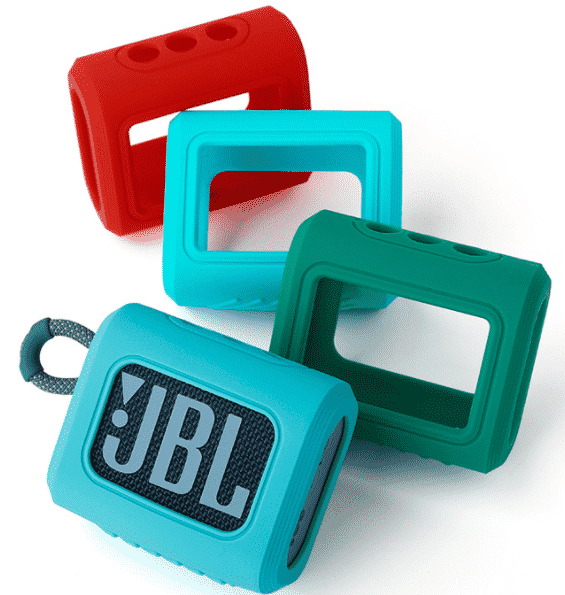

One such item is silicone sleeves. Silicone sleeves have a wide range of applications in our daily life, including kitchenware, electronics, water bottles, sports equipment, medical devices, and beauty products.

The Benefits of the silicone sleeves:

Highly Protective: Silicone sleeves can protect objects from scratches, impacts, and damage caused by exposure to extreme temperatures, moisture, chemicals, and UV radiation. For example, silicone sleeves can protect electronic devices, glassware, and pipes from damage.

Shock-Absorbing, Lightweight and Highly Functional: Silicone sleeves offer a non-slip grip that makes it easy to hold onto objects, even when they are wet or greasy. This is particularly useful for items like water bottles, kitchen utensils, beauty products and tools. Silicone sleeves can provide thermal insulation to keep hot or cold objects at their desired temperature making them ideal for use in applications like coffee cups, water bottles, and food containers.

Durability: Silicone sleeves are highly durable and can withstand exposure to extreme temperatures, chemicals, and UV radiation. They are also resistant to tearing, abrasion, and punctures, which makes them ideal for use in harsh environments.

Easy to clean: Silicone sleeves are easy to clean and can be washed with soap and water or placed in a dishwasher. Such properties make them ideal for use in applications where hygiene is essential, such as in the medical or food processing industries.

Customizable: Silicone sleeves can be customized in terms of size, shape, and color to meet your specific application requirements. This makes them ideal for use in a wide range of industries, including automotive, aerospace, medical, and consumer goods.

What Are The Benefits Of Printing A Logo or pattern On your silicone Sleeves?

There are many benefits to printing a logo on silicone sleeves, including:

Brand Awareness: Showcase Your Brand with Custom silicone sleeves Featuring Your Company Logo : With top-of-the-line custom silicone sleeves with company logos.

Promotional Opportunities: The silicone sleeves was Designed exclusively for businesses, resellers, and promotional product suppliers

Customization: The custom silicone sleeves not only deliver outstanding , but they also serve as a powerful means to personalize devices and elevate your brand’s presence.

Versatility. Boost Your Brand Recognition with Custom silicone sleeves with Company Logo,Maximize Profit Potential with Wholesale Custom silicone sleeves for Resellers and Retailers

Printing your logo on silicone sleeves is an excellent way to promote your brand and increase awareness. It offers a wide range of benefits, including durability, customization, versatility, and high-quality image reproduction. Whether you are looking to create promotional items or simply brand your products, printing a logo on silicone rubber sleeves is an affordable and effective way to achieve your marketing goals.

CNC milling logo on the silicone mold/tooling on silicone sleeves.

Debossed or embossed logo are engraved directly on tool molds during CNC mold-making process is one choice to put your logo or pattern on your silicone sleeves. That will save the cost for post process.

a: Embossed logo or pattern on Silicone Sleeves

b: Debossed logo or pattern on Silicone Sleeves

Epoxy dripping logo or pattern on Silicone Sleeves

The Epoxy dripping logo and pattern allow you to put your multi-color logo or pattern put one the silicone sleeves without printed. They can make embossed logo and debossed logo also. See the picture to get the difference

a: Embossed logo or pattern on Silicone Sleeves

Laser Engraving Logo or pattern on Silicone Sleeves

Engraving, marking, etching: call it what you want, but this technology is great for imprinting images onto a surface. It’s a permanent mark that simply can’t wear off.

You also can choice put your silicone sleeves logo or pattern by laser engraving.

Screen Printing LOGO or pattern on Silicone Sleeves

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. You may can choice put your pattern or logo on silicone sleeves by screen printing.

Pad Printing LOGO or pattern on Silicone Sleeves

The pad presses into the ink on the printing plate. The image sticks to the pad and transfers easily to anything from bowls to lightbulbs to silicone sleeves.

Heat Transfer Printing LOGO or pattern on Silicone Sleeves

The benifits of Heat transfer printing the logo or pattern on the silicone sleeves : Can get multi-color, mixed color, fading, Camouflage, Carbon Fiber, Wood Grain colors/Can Change color and pattern by FilmHeat transfer printing is widely used as it creates durable, heat resistant, adhesive and water-resistant designs. Additionally, the colours created in the image are high resolution with bright and bold colours. So, Your silicone sleeves is more cute.

Water Transfer Printing LOGO or pattern on Silicone Sleeves

The water transfer printing are wide ranges of water transfer printing films and the most popular patterns include camo, wood grain, carbon fiber, marble, and camo. The camo film is the most popular pattern and is also the common pattern for hydro-dipping guns.When you need get the silicone sleeves color like that ,you need choice the water transfer printing method.

In-Mould Decoration LOGO or pattern on Silicone Sleeves

In-Mold Decorating provides original equipment manufacturers (OEMs) and molders an alternative method for decorating silicone sleeves. With IMD, graphics are printed on a film, using one or a hybrid of several printing processes, which is then inserted into a mold cavity to get a custom logo or a pattern on silicone sleeves as the clients needed.

Related Blog

Conclusion

Printing a logo or pattern on silicone sleeves is a great way to give your brand a professional look and feel. With the right tools and techniques, you can easily print your logo on to silicone sleeves with high-quality results. We hope that our guide has helped you understand how to print a logo or pattern on silicone sleeves so that you can create stunning products for your business.

So If you need :

- Custom silicone sleeves with Company Logos for Your Business

- Elevate Your Business with Custom Company Logo silicone sleeves as Promotional Gifts

- Connect with ZSR Today to Enhance Your Brand’s Visibility with Custom silicone sleeves.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.