How to create private silicone mats?

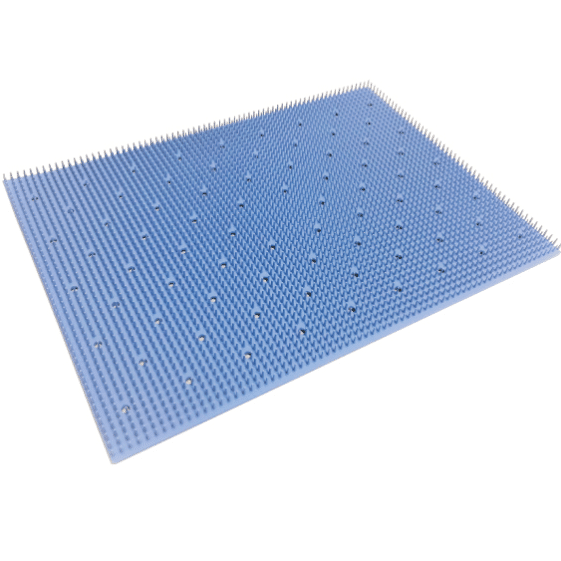

This article mainly introduces the advantages, production equipment, production process, etc. of silicone mats. If you want to create your own silicone mat brand or business, and have a clear understanding of the advantages, application areas, design, and production process of silicone mats, please go through this article. Silicone mats have the advantages of high and low temperature resistance -40-230°C, Recyclable, and environmental protection. They are widely used in kitchens, baking, beauty, personal care, furniture, and medical or industrial areas.

Silicone mats can be used for anti-slip, protection and cushioning, heat insulation and scald prevention in your daily life.

When you need reduce machine vibration and noise, and improve the stability and service life of the machine, you may need the silicone mats for industry used.

Silicone mats also can used for shockproof and shock absorption of medical equipment, such as medical operating tables and operating beds, which can improve the accuracy and safety of surgery.

Silicone mats can be used for anti-slip, anti-shock, and anti-wear. For example, when used under mobile phones, computers, cameras and other devices, it can protect the device and reduce the risk of accidental drops.

What is the Silicone mat?

Silicone mats are usually made of 100% food grade silicone rubber or food-grade, fiberglass-reinforced silicone.

They are all high elasticity, pressure resistance, high temperature resistance and low temperature resistance.

It is also chemically stable, BPA-Free, Oven & Dishwasher Safe, environmentally safe and odorless.

In Household: home and houseware products

- The fiberglass-reinforced silicone made silicone mats always use in baking and much high temperatures from -40° C to +280° C. It can be silicone baking mat, silicone fusing mat etc. need more high temperatures area. They can be Multi-purpose Mat. Use it as a baking, roasting, cooling, or craft mat, trivet, drying rack, freezing mat, and more. Thick baking mat made from silicone-coated glass fiber canvas, can be used for hot or cold work to replace disposable baking paper. They create the perfect work surface simply by rolling out this silicone baking mat! Nonstick mat won’t scootch or slide on your countertop and makes cleanup a breeze. It’s great to use as a pastry mat to roll out dough and pizza crusts, shape breads, buns, braids, and other sticky baking projects.They also can Keep baking pans clean and prevent food from sticking with this easy-to-wipe heat-proof silicone mat.

- The 100% food grade silicone mats always used as crafts mats, baby place mats, Liquid, Resin Jewelry Casting Molds Mat, Silicone Placemat, Silicone Mats for Kitchen Counter, Silicone no mess mats, On-slip Waterproof Large Countertop Protector Mat, Heat Resistant Mat. These silicone craft mat range in size and are perfect for painting, pours, cement/plaster, slime, clay, resin, and just about anything else you can dream. The silicone mats are odorless, non-toxic, dust-proof, non-stick and anti-slip with printing is the ability to customize them to match your style and needs. The Mat features a 100% silicone non-slip mat so your items stay put. and protect all your table, counter and anything you would like to protective.

In Medical area

- The silicone mats can be used for cushioning and protection of medical equipment to ensure safe operation and patient comfort.

- The medical-grade silicone mat is designed to hold, organize and protect surgical instruments within a tray during sterilization. They can protect your precious instruments during cleaning and storage.

Industrial mechanical area

The silicone mat used for shock absorption and sound insulation of mechanical equipment is typically called a vibration damping pad or anti-vibration mat; it is designed to reduce noise and vibrations generated by machinery, thereby improving work efficiency and extending the life of the equipment by minimizing wear and tear from excessive vibrations.

Electronic Industry

Used for insulation and protection of electronic equipment to prevent static electricity and electromagnetic interference.

The silicone mats also widely used in other Fields: Such as automotive accessories, sports equipment, etc., providing good shock absorption and comfort.

What are the advantages of silicone mat?

Environmental protection and non-toxicity: Silicone mats are made of environmentally friendly food grade silicone material, non-toxic and tasteless, insoluble in water and any solvents, and are highly active green products. Food-grade silicone mats are non-toxic and tasteless, and are suitable for various occasions that require safety assurance.

Durability: Silicone pads or mats usually have a long service life, are not easy to dent, and can maintain good support. In addition, the silicone pad has stable chemical properties, high temperature resistance 230 C, low temperature resistance -40 C, pressure resistance, environmental protection and safety, and no odor.

Tension and flexibility: The silicone pad or mat has a certain tension and flexibility, which can provide good support and cushioning effects in different application scenarios.

Easy to clean: Silicone pads or mats are oil-free and flexible. Even placemats with complex shapes can be easily cleaned without breeding bacteria in the gaps

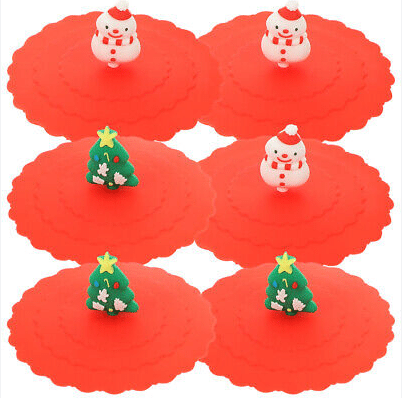

Diverse shapes and appearance: Silicone mats come in a variety of styles, including simple style, cartoon style, multi-element style, etc., to meet different aesthetic needs. which are environmentally friendly and non-toxic, with excellent thermal insulation performance, which enhances the overall temperament of the restaurant while providing safety protection

Comfortable feel: Silicone placemats are soft silicone, comfortable to the touch, and different from traditional hard mats

Recyclable: Silicone placemats do not require felling trees. The material what they used from sand and can be recycled, making them environmentally friendly

Z.S.R offers various Custom silicone mats with different shape and colors for different industry used such as kitchenware, homeware, baby, Medical ,Promotional etc .

Silicone Placemats

Materials, Tools, Equipment

According to the molded products making process, there are 5 ways of silicone molding process: silicone rubber compression molding, LSR injection molding, silicone Drip molding, silicone Extrusion Molding, silicone Calendaring molding. Here in Z.S.R, For silicone mats, we only have 4 molding process capacity. The different molding process need the different material, tools and equipment:

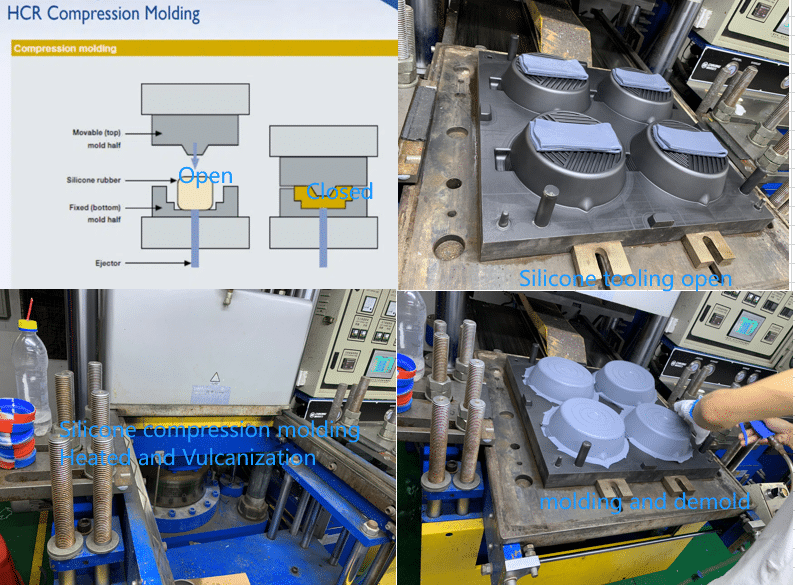

Silicone compression molding

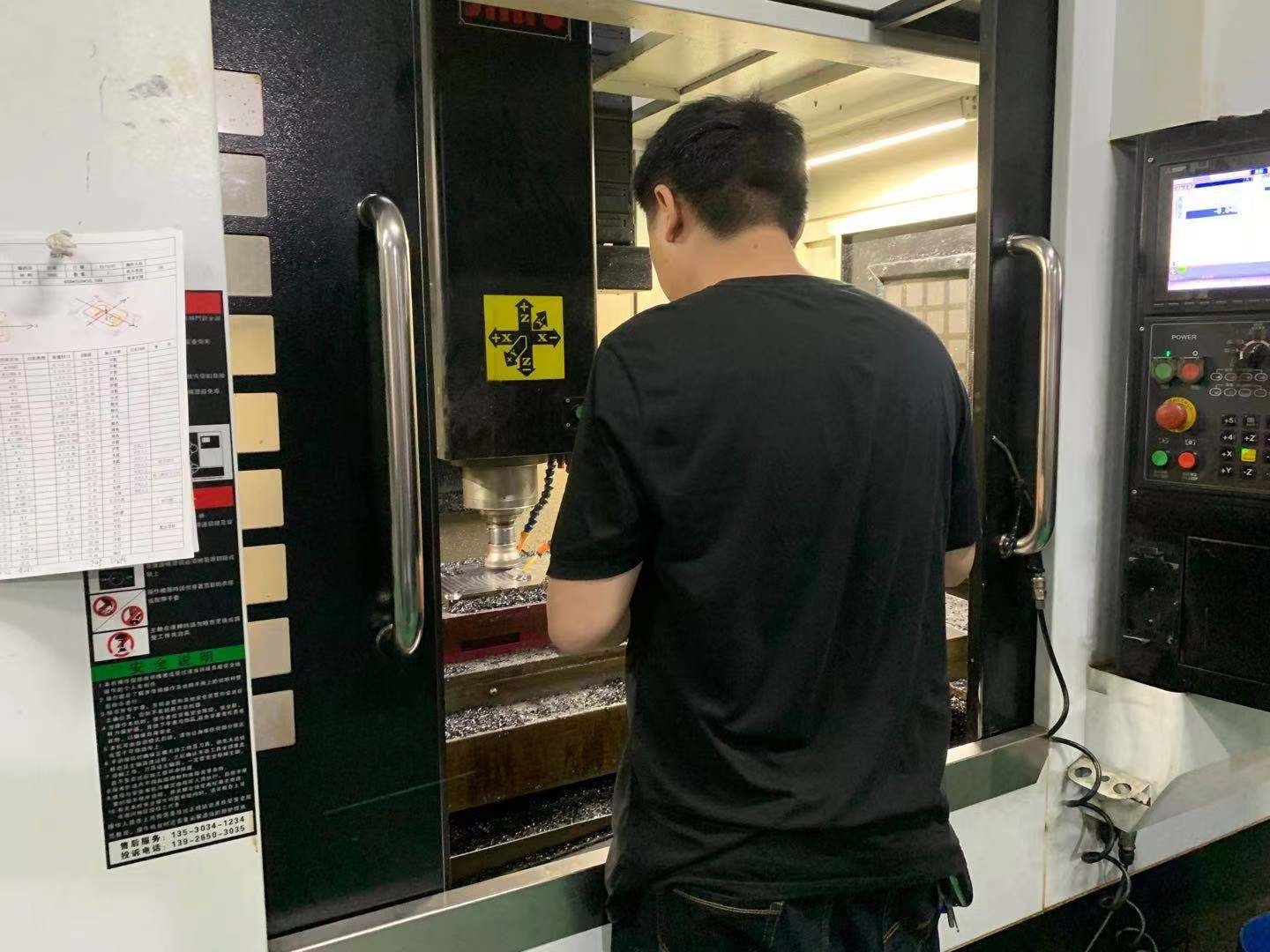

Silicone Compression Molding

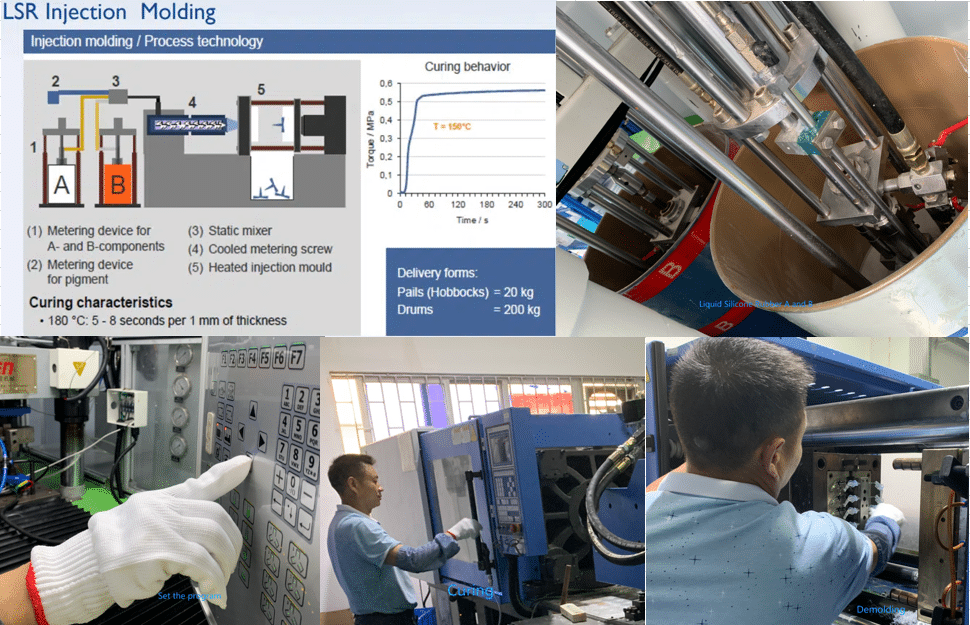

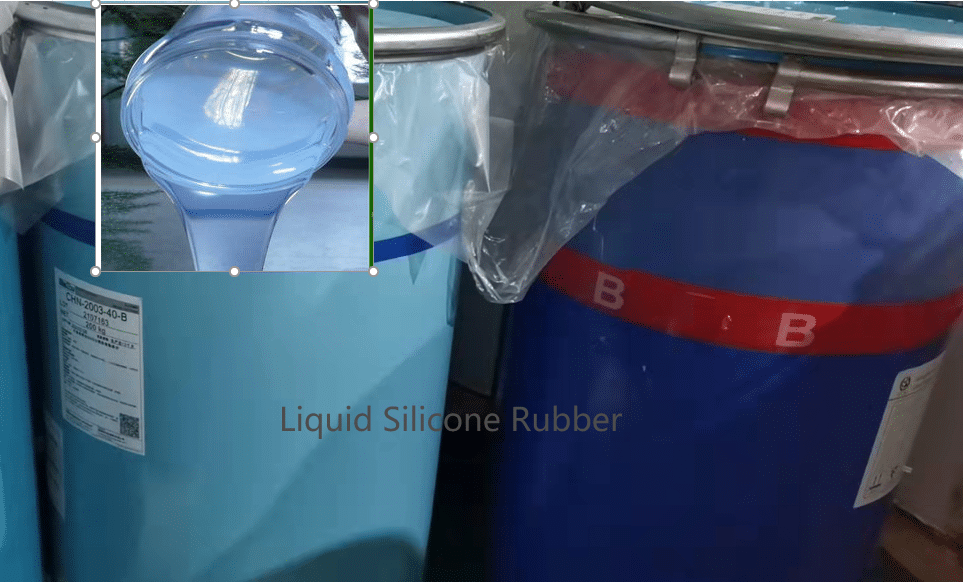

L.S.R injection molding

Liquid Silicone Rubber (LSR) Injection Molding

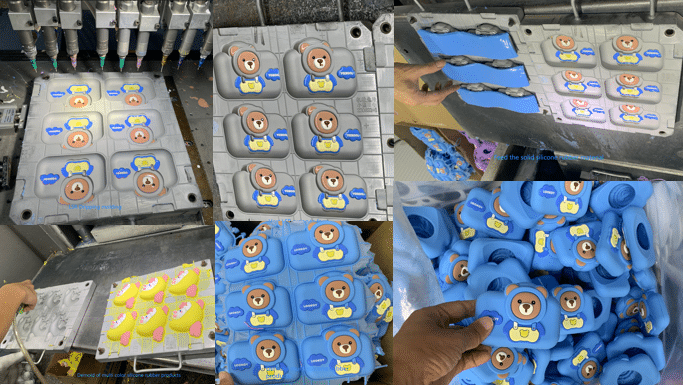

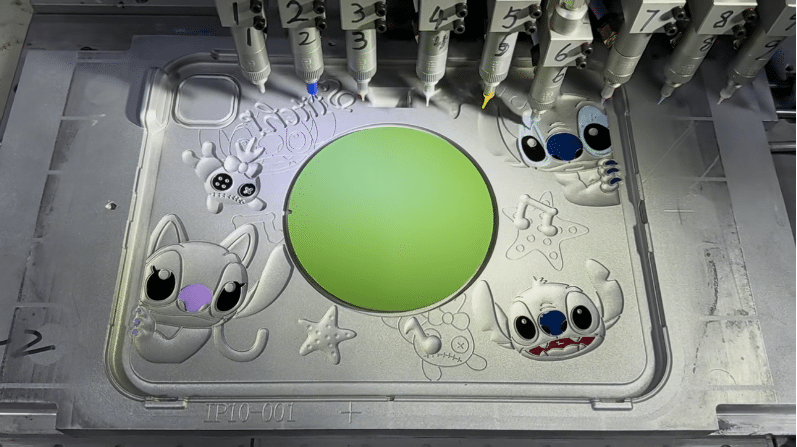

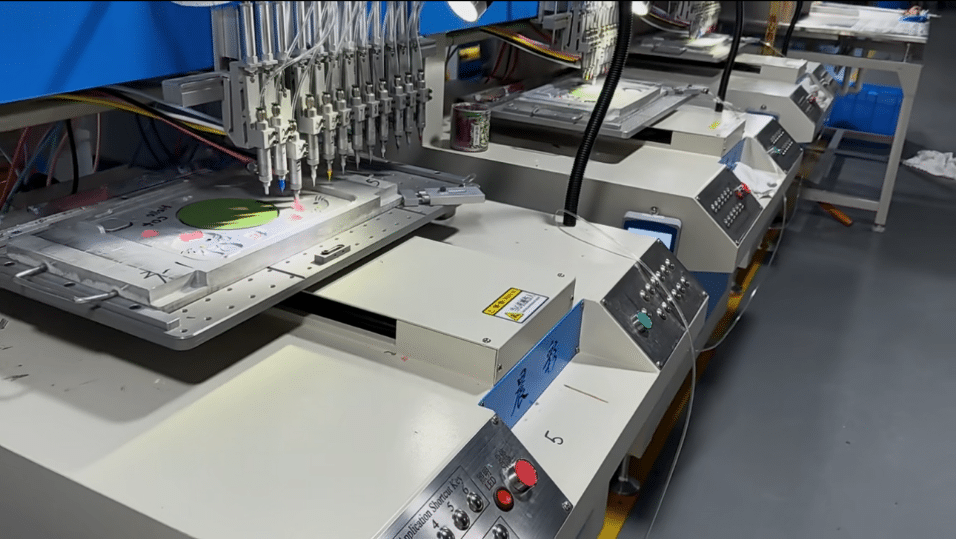

Silicone Dripping dispensing molding

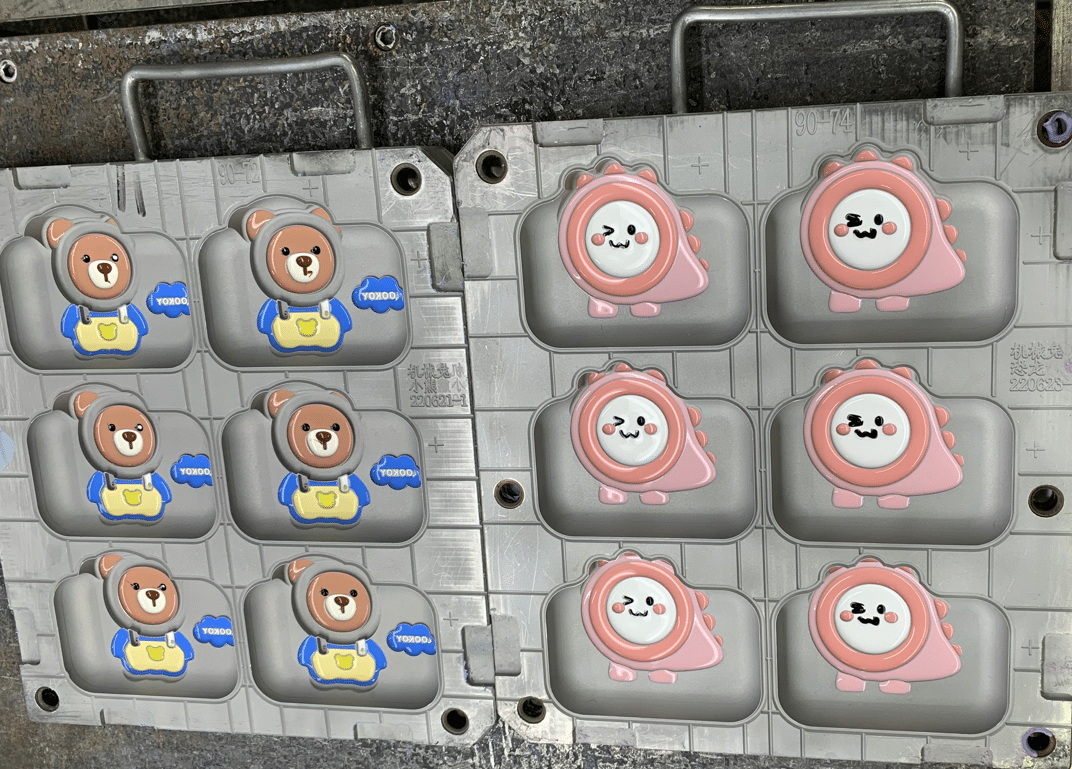

Multi-Color Dripping Molding

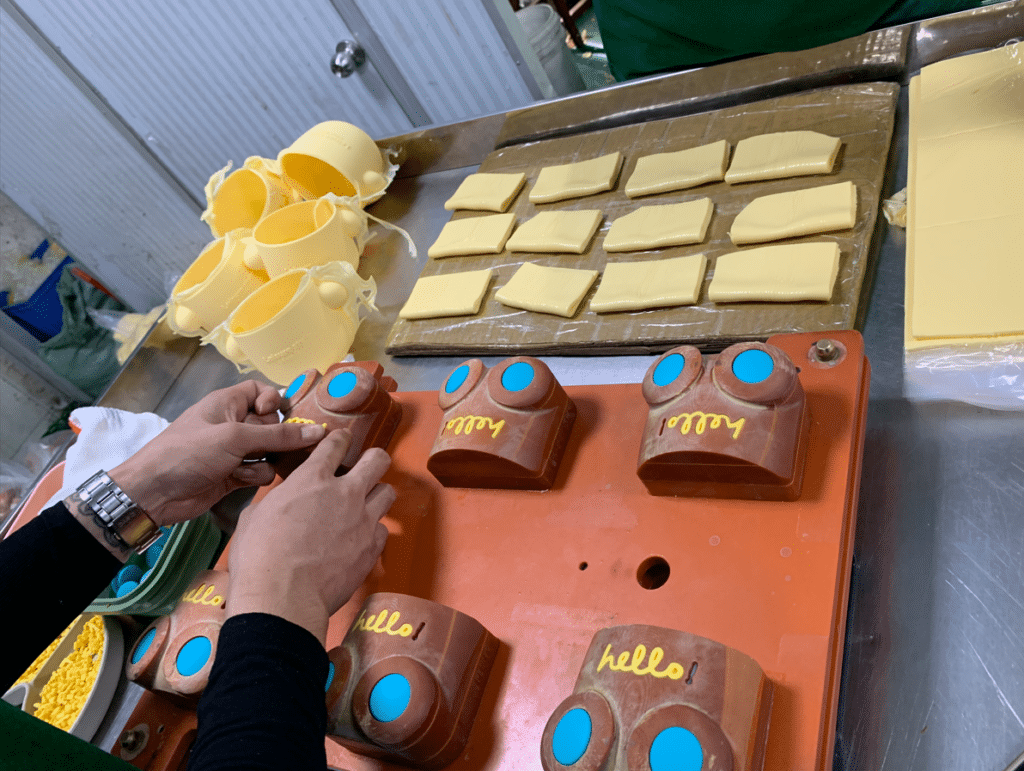

Need prepare silicone as the main material for dispensing molding, usually liquid silicone (LSR) and solid silicone, color paste, vulcanizer, and also need silicone vacuum machine and automatic dispensing machine. As this kind of molding have two kind of molding process. We also call them co-injection molding. Mixed L.S.R material dripping from the automatic dispensing machine first, then heat and curing. Put the solid silicone rubber material on and close the molds put them silicone vacuum machine Vulcanization molding.

The customization process for create your private silicone boots

In Z.S.R, we can custom the silicone boot shape, size, color, pattern, brands, logo by silkscreen printing, full-color printing, or laser engraving for your silicone products, if you would like to custom your brands silicone boots contact Z.S.R.

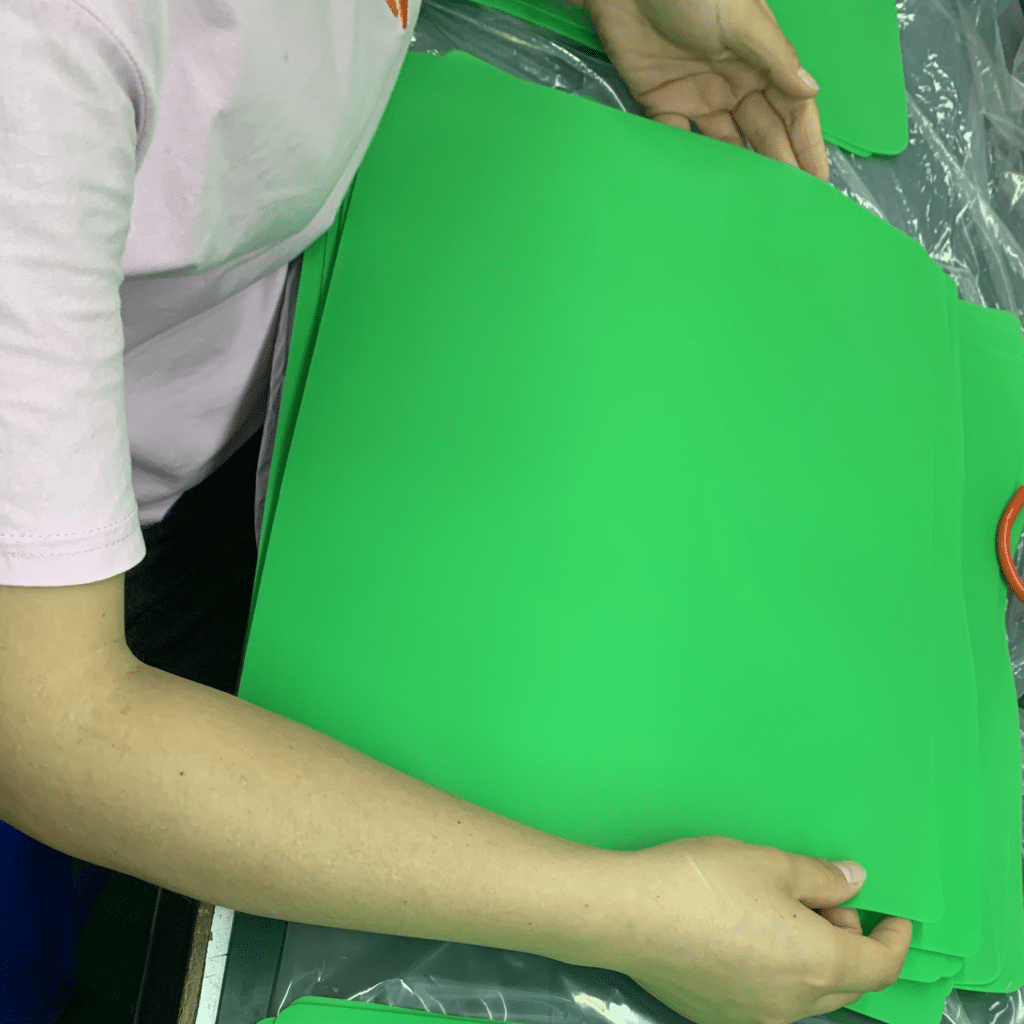

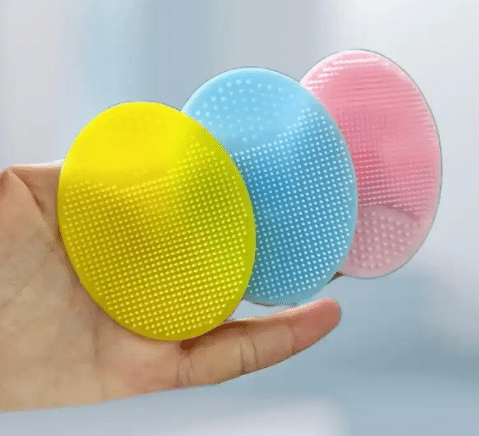

Appearance (shape, color): Shape can be round, square or creative shape by developing the new tooling. The color can be white, blue, black or use the pantone book number to customized. You also can get mixed color, marble color or double colored, multi-colored appearance.

Material properties: You can customization the material with HTV material or LSR material. The hardness you can choice from 5-80 shore A, Translucent to highly transparent, Safety level from Food Grade to Medical grade, tensile properties from ordinary to high level)

Mold type: Steel, Copper or Al

Molding method:LSR Injection molding, HTV compression molding, dripping molding

Labeling: Logo on the tooling and get the logo products. We also can Screen Printing,Laser Engraving,Heat Transfer Printing your logo on the silicone boots already.

Packaging: zip bag, back card PET box, color box

Shipping method: DHL, FedEx, Air shipping or Sea shipping

How to create your silicone boots brand or start your silicone boots business?

1. Choose the design and style of the silicone molded products that you want to customize from Z.S.R’s existing designs. Or Starting with your new product idea to create your molded products, our engineers can proceed with the CAD/Stp/Step/X-T drawings just based on your sketches.

Our design and manufacturing engineers will work with your team to ensure designs meet processing requirements and can be produced consistently and cost-effectively. For your ODM or OBM project, we can sign an NDA non-disclosure agreement with you. It wards off any copycats that plagiarize your designs.

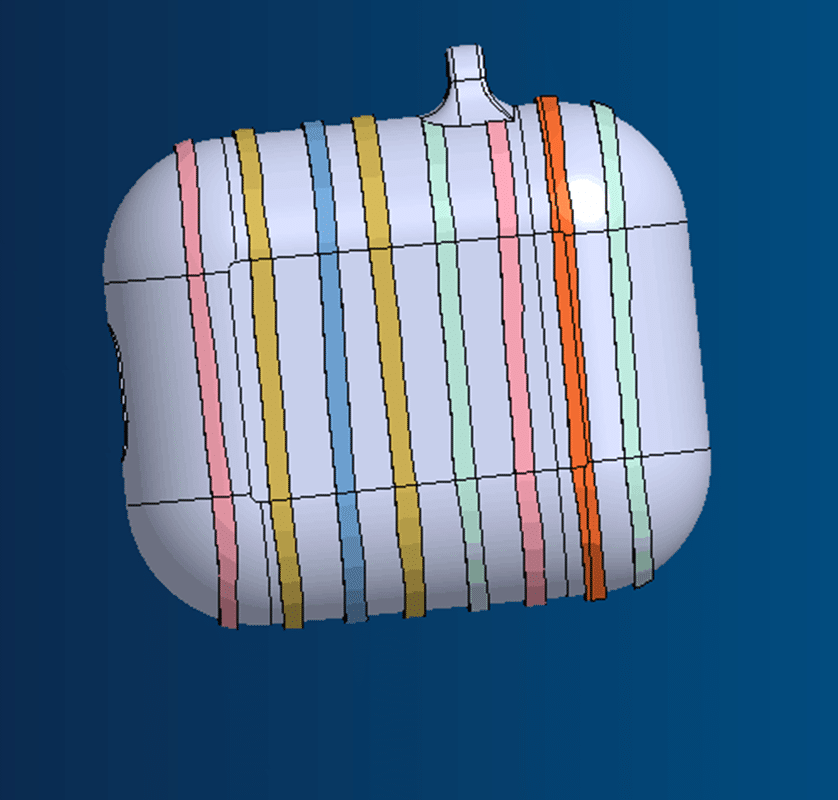

Design 3D structure of the silicone mat according to your idea.

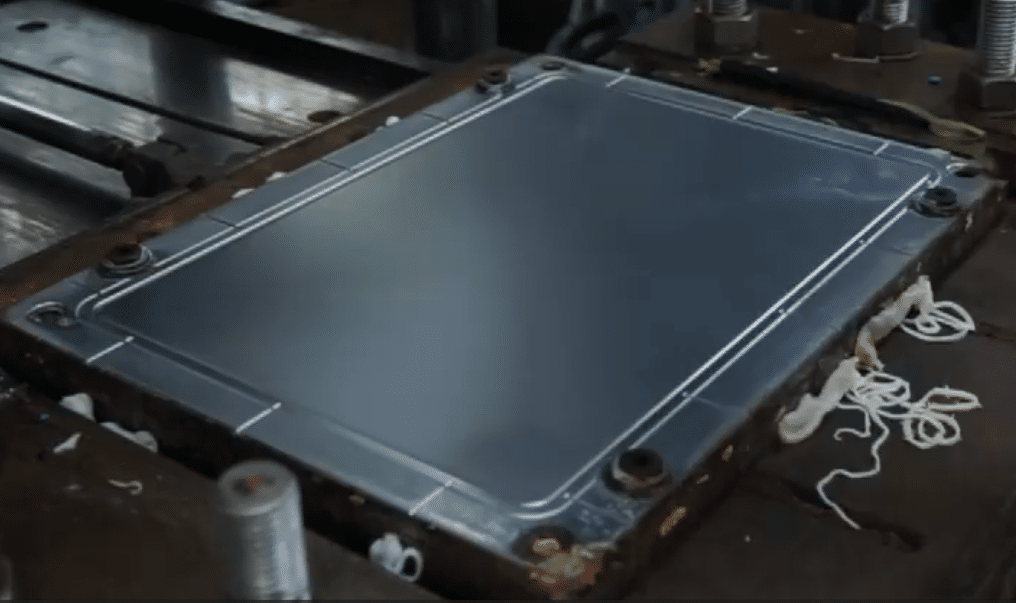

2. Z.S.R will make the prototype tooling to get the prototype to let you confirm. If all go through, we will make the mass production tooling for you and remake the samples for get your approved confirmation samples. Make the silicone mat tooling according to the silicone mat design requirements (Signal color or multi color) use the different metal, such as steel, copper or AL to ensure the accuracy and durability of the tooling.

3. Prepare the silicone mat raw material: Raw silicone material are the key to silicone mats’ products. Usually, Silicone mats meet certain environmental protection standards, so silicone mat material are no exception. Normally, environmentally friendly Fumed silicone rubber is selected for customized processing, while many manufacturers use Precipitated silicone rubber for processing. Although the product is not greatly affected, it is still different Fumed silicone rubber from in quality after a long time. Mix the silicone color according to your silicone mat needed. Cutting the mixed silicone material in the correct weight.

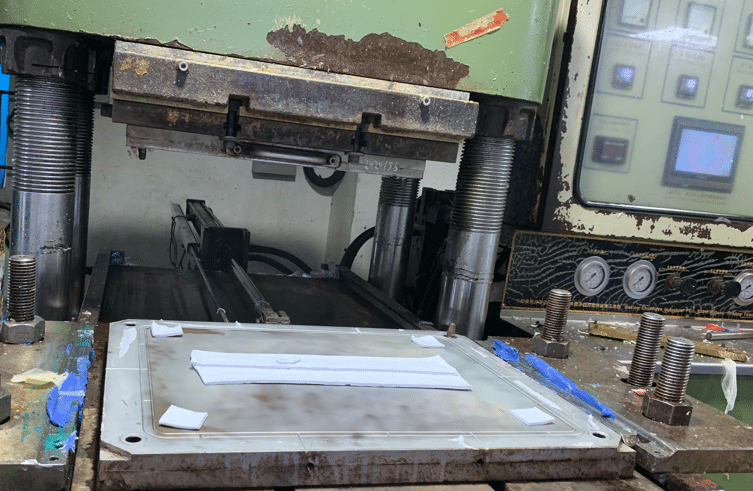

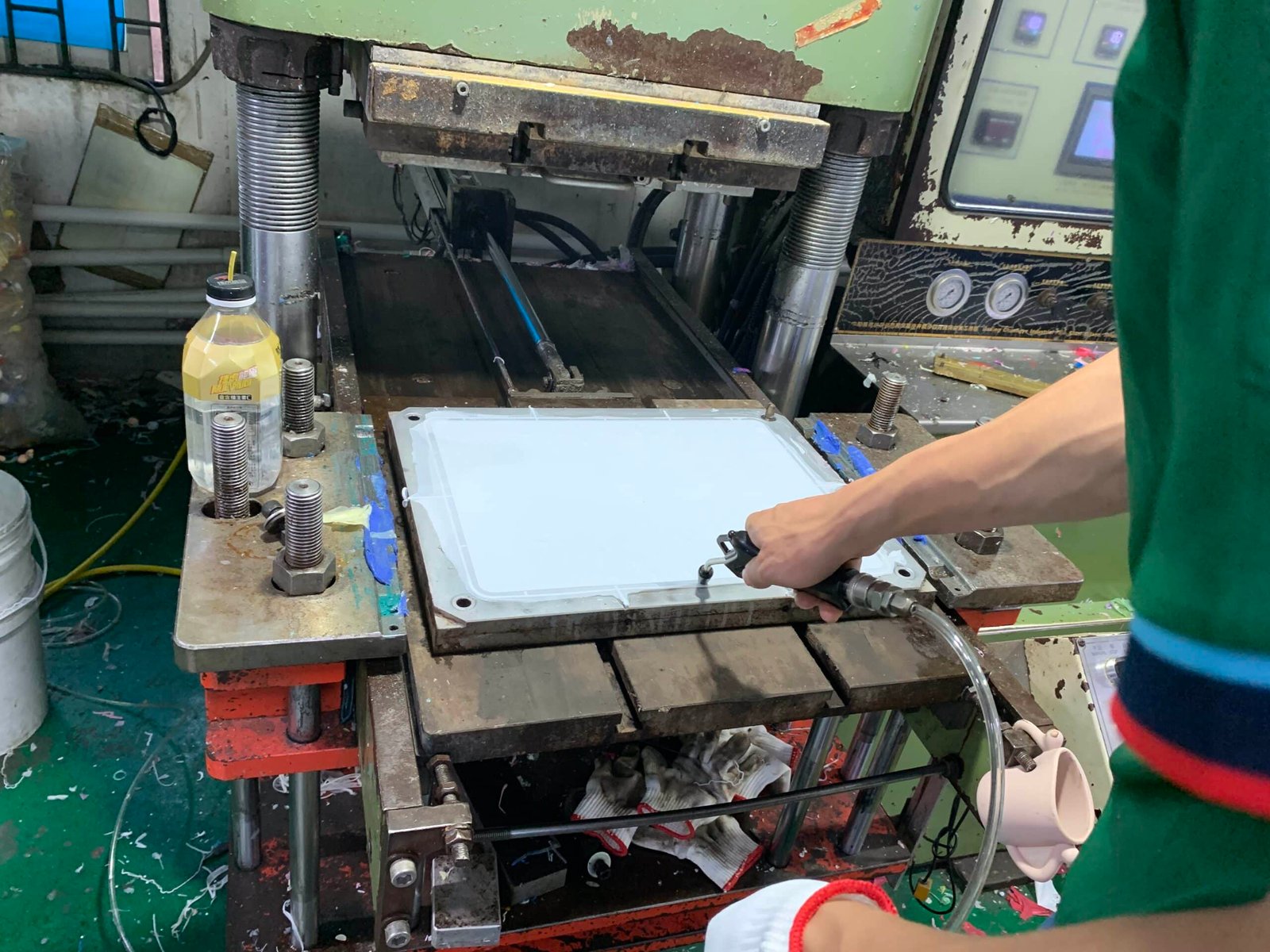

4. Feeding the prepared silicone mixed silicone material on-Feeding the silicone mat material no matter the Liquid silicone rubber or solid silicone rubber in to the mold.

5. Curing the silicone mat: The silicone mats material is feeding into the mold after mixing, and the silicone mats material is filled into the entire space of the mold through heating and pressure. The temperature, pressure and time control of the molding process directly affect the size, shape and quality of the product.

No silicone matter the silicone mat was made by: Compression molding or silicone dripping molding or LSR molding.

6. Demolding: After the curing is completed, take the silicone mat product out of the mold.

7. QC the silicone mat: Quality inspection: Visually inspect the molded silicone mat to see if there is lack of silicone mat material, uncooked Ness, or impurities.

8. Post-processing: Carry out the silicone mat and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

9. Secondary vulcanization: Secondary vulcanization is a process that must be handled for any product that has passed the inspection. The main reason why infant silicone mats have a certain smell is that they have not been subjected to Secondary vulcanization baking, and the catalyst of the raw silicone mats material of the products has not been emitted. At present, many silicone children’s product manufacturers basically handle it, but the time and temperature of the Secondary vulcanization treatment are different. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone mat may do not need this process.

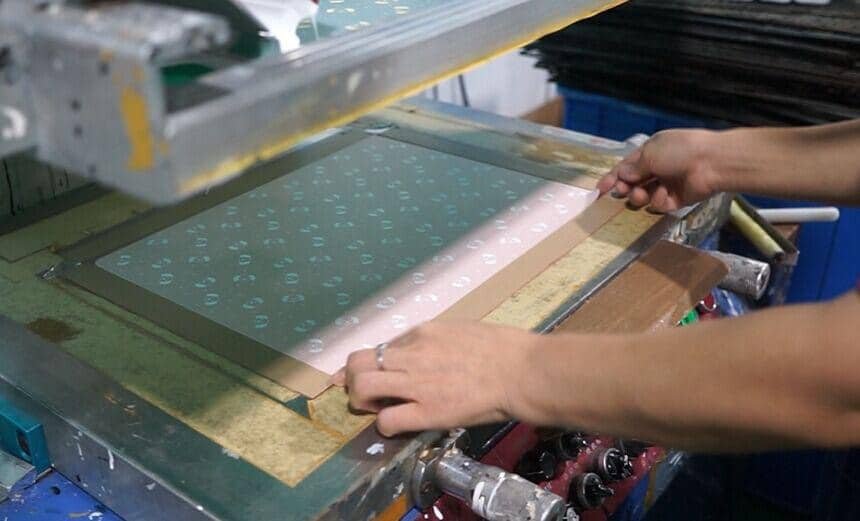

10. LOGO or Pattern printing on the silicone mats if needed: screen printing or laser engraving. Most of time, we put the silicone mat logo on the silicone tooling directly. Check the products branding service to know more.

11. Final Quality control and testing: After all the silicone mat making process finished, we will arrange the final QC for the silicone mats before the delivery.

12. Package and Warehouse: Z.S,R offer custom packaging solutions you need for all your product packaging. Our custom packaging includes paper boxes, PE/PVC boxes, printed labels, hangtags, barcode stickers, etc to protect the safety of the product during transportation and storage, while ensuring the safety and aesthetics of the product.

As a silicone mat manufacturer in China, we manufacture the silicone mats according to the client’s design and idea. We try our best to deliver the quality silicone mat to our customer.

Notice

When you buy the silicone mat, should pay attention to:

- Material and Certification: The silicone mat should meets your needs and is non-toxic and environmentally friendly to ensure safe use. lead, PVC-, and phthalates-free. Check whether the silicone mat product has a safety test certificate to ensure that it meets the relevant food safety standards. In China, silicone mat products can be checked for compliance with the limit requirements of GB 4806.11-2016 “National Food Safety Standard Food Contact Rubber Silicone material and Products”, while foreign products should be checked for US FDA certification, CPSIA certification or EU LFGB certification, etc. Food-grade silicone is preferred, IN USA -FDA Approved -silicone mat. The silicone mat should be 100% food-grade silicone material to ensure safety. Ensuring that it complies with FDA and LFGB standards. Avoid choosing silicone mat made of ordinary plastics because they may release harmful substances.

- Feel and appearance: Good silicone mats have a smooth feel, uniform color, and no impurities on the surface. Poor ones have a sticky feel, a rough surface, different shades of color, and even impurities.

- Safety: Avoid choosing imitation liquid silicone mats containing harmful sulfides, as they may contain harmful substances and affect health.

- Brands and channels: Prefer well-known brands to ensure quality, purchase through formal channels, and avoid buying counterfeit and shoddy products.

- Price and cost-effectiveness: Prices range from a few yuan to hundreds of yuan. Cheap products may turn yellow, feel bad, or easily get hairy. You get what you pay for, choose the product that suits you.

- Functional requirements: Choose silicone mats with anti-fingerprint, dustproof, antibacterial and other functions according to personal needs.

When you would like to buy the silicone mat, you should comprehensively consider factors such as material, safety, brand, Function, and size to ensure a safe.

Conclusion

No matter you would like to create the silicone mat with your logo or design for sales, promotional or events. Our high-quality customize silicone mats are perfect for branding, souvenir , corporate gifts.

Z.S.R. customized branded silicone mat with added your logo, design pattern, text may be your good choices.

In Z.S.R, all the steps from raw silicone mats material selection to molding, curing, and quality control, each step plays a vital role in creating your silicone mat that meet safety standards and perform well in their intended applications.

Contact Z.S.R to brand your own silicone mat by contract manufacturing.

Related Article

How to create your molded silicone products?

How to create private silicone protector?

How to create private silicone trays?

How to create private silicone sleeves?

How to create private silicone shower scrubber or body scrubber?

How to create private silicone plate?

How to create private silicone placemats?

How to create private silicone molds?

How To Create Your Silicone Cups?

How To Create Your Silicone Cases?

How To Make silicone boots?

How To Make Silicone Lids?

How To Make Silicone Bowls?

How To Make Silicone Earbud/Earphone Cases?

How to Make Your Silicone Brushes/Scrubbers?

How to Make Silicone Caps: Materials, Tools, Equipment

How to Make Silicone Bags: A Comprehensive Guide from Material Selection to Finishing Touches

How to make air fryer silicone pots or silicone air fryer liner?

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.