How to create private silicone shower scrubber or body scrubber?

This article mainly introduces the advantages, production equipment, production process, etc. of silicone shower scrubber or body scrubber. If you want to create your own silicone shower scrubber or body scrubber brand or business, and have a clear understanding of the advantages, application areas, design, and production process of silicone shower scrubber or body scrubber, please go through this article. Silicone shower scrubber or body scrubber have the advantages of Soft and comfortable, Antibacterial and antibacterial , Strong durability. They are widely used in baby, cosmetics,personal care, medical or industrial areas.

- Daily bathing and cleaning: The silicone body scrubber can easily produce rich and delicate foam to clean every part of the skin, suitable for daily bathing.

- Sensitive skin and children: The silicone body scrubber is made of environmentally friendly silicone material, which is non-toxic and odorless, PVC,BPA Free, soft to the touch, and suitable for people of all skin types, especially sensitive skin and children can use it with confidence.

- Baby bathing: The baby silicone body scrubber can help clean the baby’s hair and body due to its soft silicone material and comfortable touch, while performing gentle massage to promote blood circulation, allowing the baby to feel relaxed and comfortable while enjoying a bath.

What is the Silicone shower scrubber or body scrubber?

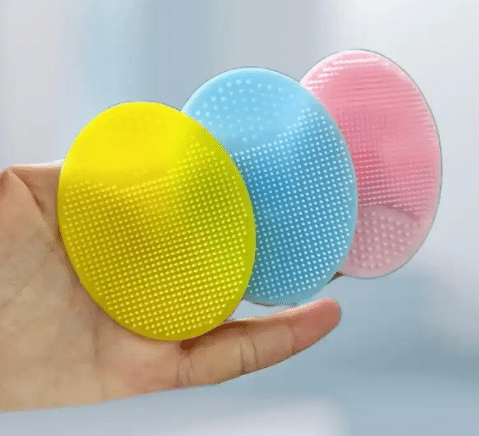

Silicone Body Scrubber is a bathing tool made of environmentally friendly silicone raw material. It is non-toxic and odorless, resistant to high and low temperatures, soft to the touch, skin-friendly and non-irritating. It is mainly used for body care and massage. Silicone body Scrubber are usually soft and elastic, can fit the body curve, and provide a comfortable massage experience. Its material is usually food-grade silicone, safe and non-toxic, suitable for skin care. All skin types, especially sensitive skin and children can use it with confidence.

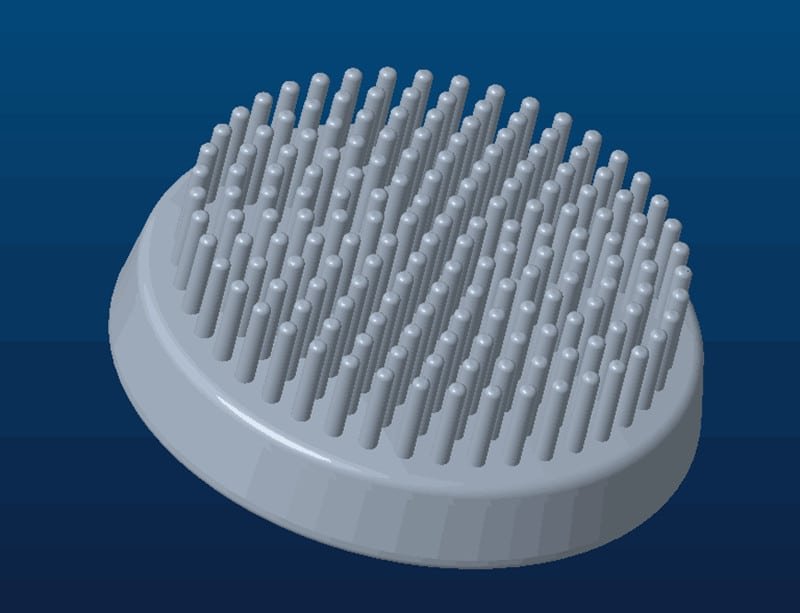

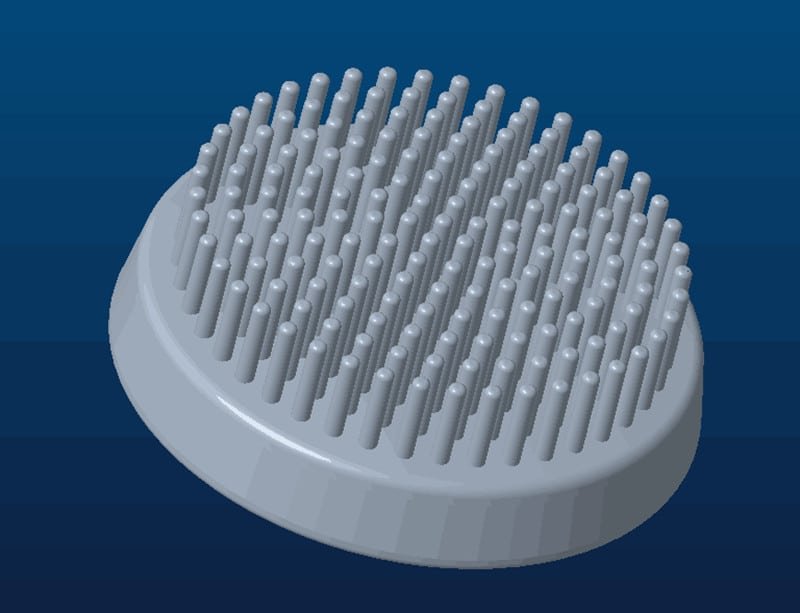

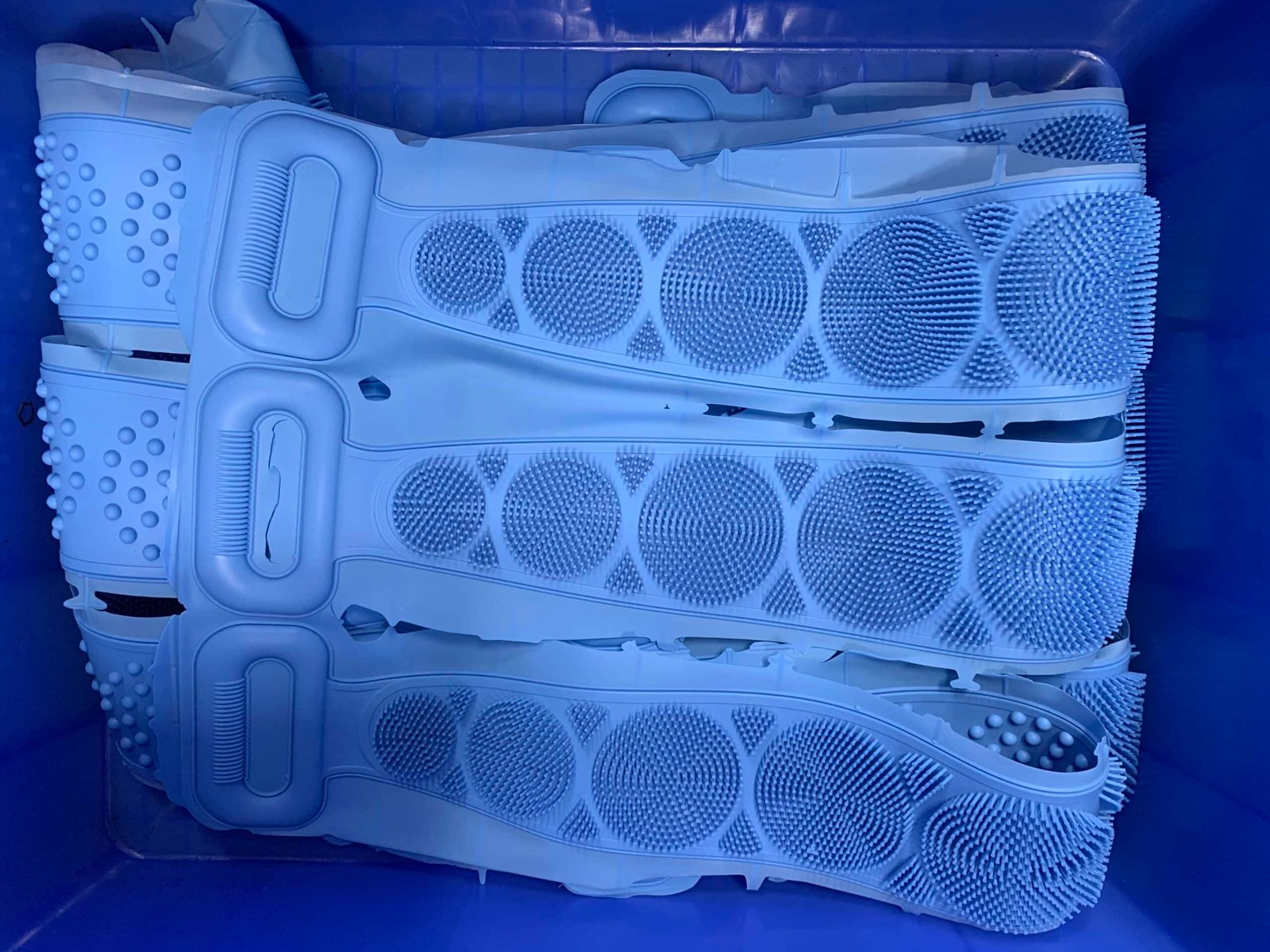

The design of silicone body Scrubber usually includes thousands of silicone bristles of different lengths, which can clean the skin 360 degrees without dead ends, help clean skin mites, remove excess surface keratin, improve the oil balance of the back skin, and make the skin clean and refreshing. In addition, silicone body Scrubber can also play a massage role during bathing, help accelerate skin blood circulation, brighten the skin, and make the skin crystal clear, delicate and rosy.

The silicone body Scrubber is Soft and elastic: The material of the silicone body scrubber is soft and elastic, Gentle Exfoliating and Lather Well,which can fit the body curve well, will not cause harm to the skin, and can be used with confidence even for sensitive skin . Safe and non-toxic: Silicone materials are usually food grade, non-toxic and harmless, and will not irritate or allergic to the skin.BPA-Free Silicone Body Scrubber for All Skin Types, Perfect Back Cleaning & Massage Shower

Versatility: Silicone body scrubbers can be used for a variety of body care and massage, such as dredging meridians, promoting blood circulation, relieving muscle tension, etc. .

Meridian massage: Silicone body scrubbers can promote blood circulation and relieve muscle tension and fatigue by brushing meridians. For example, brushing the spleen meridian can regulate spleen and stomach function, and brushing the three yin meridians and three yang meridians can improve cardiopulmonary function and upper limb blood circulation.

Shaping and beauty: In terms of weight loss and body shaping, silicone body scrubbers can stimulate fat cells through rhythmic brushing, accelerate decomposition and metabolism, and effectively reduce local fat accumulation with a reasonable diet and exercise plan Skin care and health care: Using a silicone body scrubbers can promote skin metabolism, accelerate the shedding of aging keratin, make the skin tighter and smoother, and glow with a healthy and moving luster.

What are the advantages of silicone shower scrubber or body scrubber?

Soft and comfortable: The material of the Z.S.R silicone body scrubber is soft and elastic. It feels gentle when in contact with the skin. It will not scratch the skin like some rough brushes. They gives you the 2-in-1 benefit of gentle cleansing and massaging for a relaxing experience and a full-body clean. Even sensitive skin can be used with confidence.

Good cleaning effect: The bristles of Z.S.R silicone body scrubber are of moderate length and are arranged in a staggered manner. The long bristles can penetrate deep into the skin texture and remove dirt and grease deep in the pores, while the short bristles are responsible for cleaning the surface of the skin, making the skin smoother and more delicate.It is built for deep cleansing and optimal exfoliation.

Antibacterial and antibacterial: The silicone material has good antibacterial properties, which can effectively inhibit the growth of bacteria and keep it clean and hygienic. Its physical properties reduce the survival rate of bacteria, making it suitable for use in bathroom environments with high humidity.In Z.S.R also can infuse with antimicrobial silver and zinc to resist odor-causing bacteria.

Strong durability: The Z.S.R silicone body scrubber is not easy to deform or damage and has good durability. You can knead it casually during bathing, and it can maintain a good shape whether you scrub it hard or massage it gently.

Easy to use: The Z.S.R silicone body scrubber is easy to clean. Just rinse it with clean water after bathing to remove residual dirt. Its good drainage allows the brush to dry quickly, avoiding problems with moisture that can cause bacteria to grow.

Silicone Brushes

Materials, Tools, Equipment

According to the molded products making process, there are 5 ways of silicone molding process: silicone rubber compression molding, LSR injection molding, silicone Drip molding, silicone Extrusion Molding, silicone Calendaring molding. Here in Z.S.R, For silicone shower scrubber or body scrubber, we only have 4 molding process capacity. The different molding process need the different material, tools and equipment:

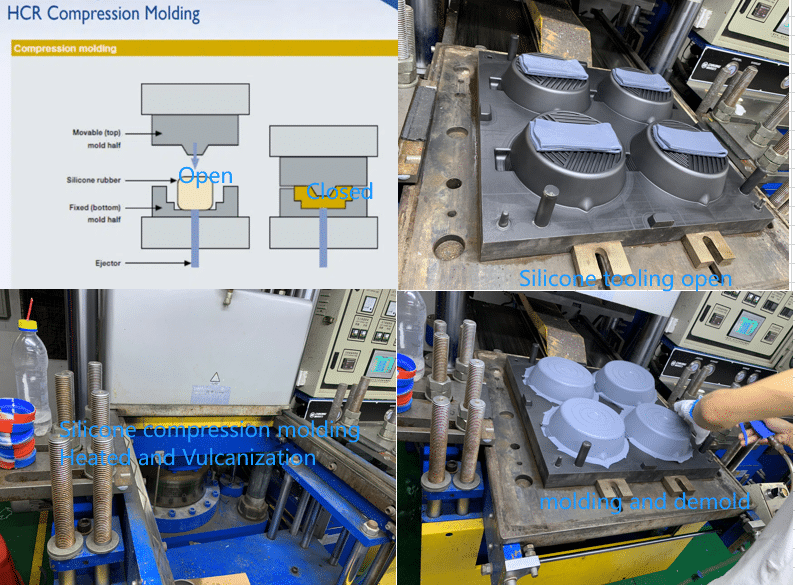

Silicone compression molding

Silicone Compression Molding

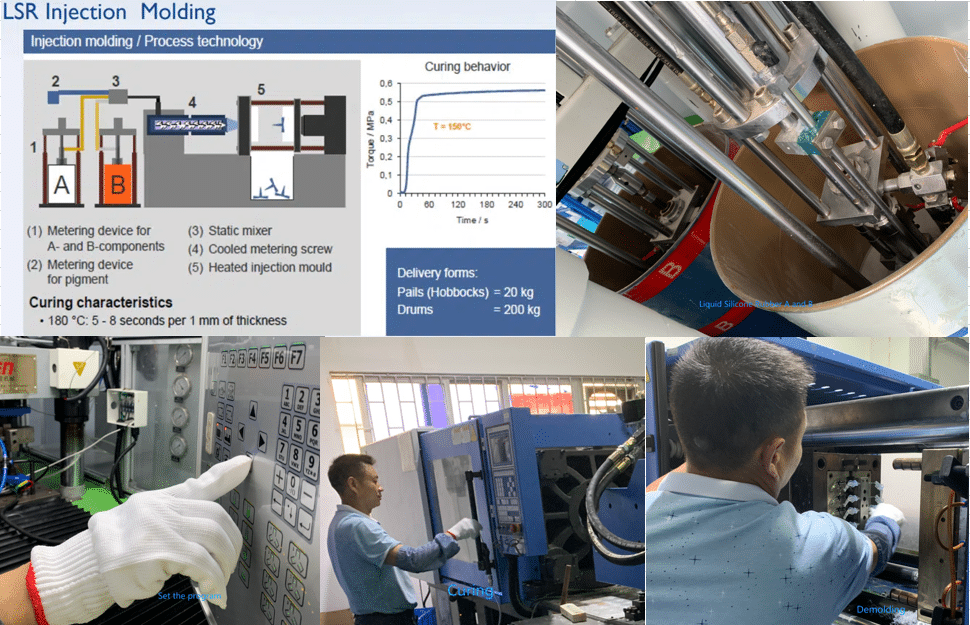

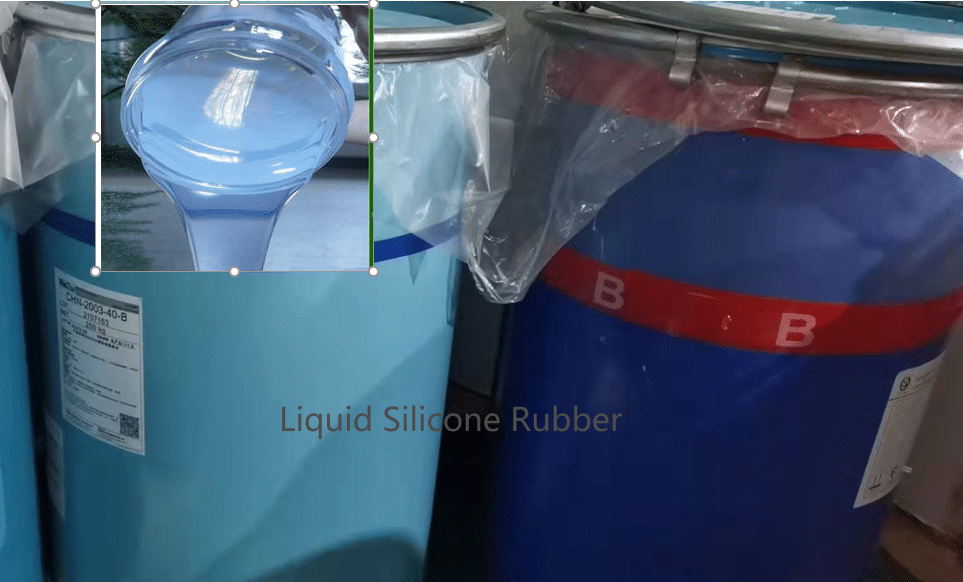

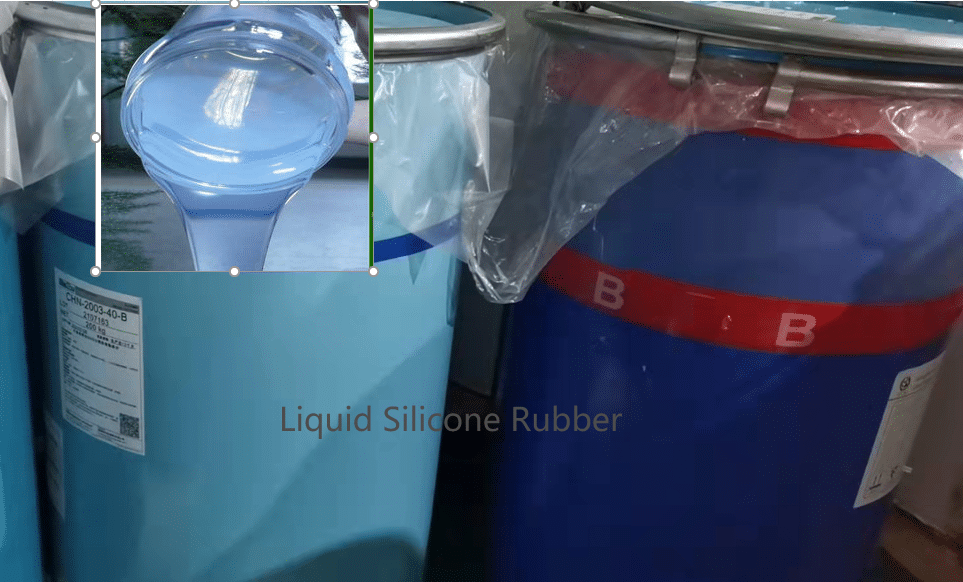

L.S.R injection molding

Liquid Silicone Rubber (LSR) Injection Molding

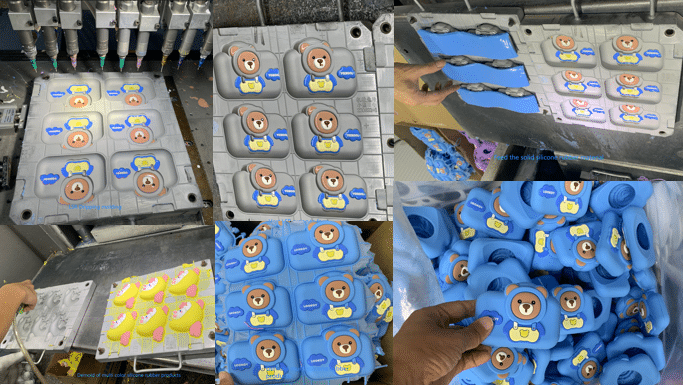

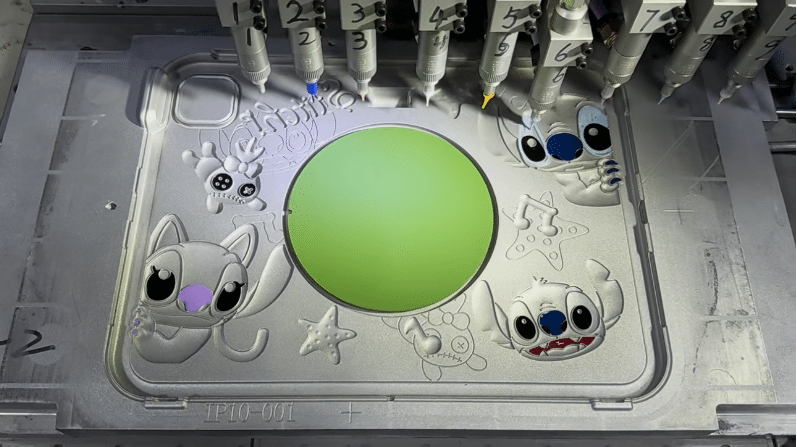

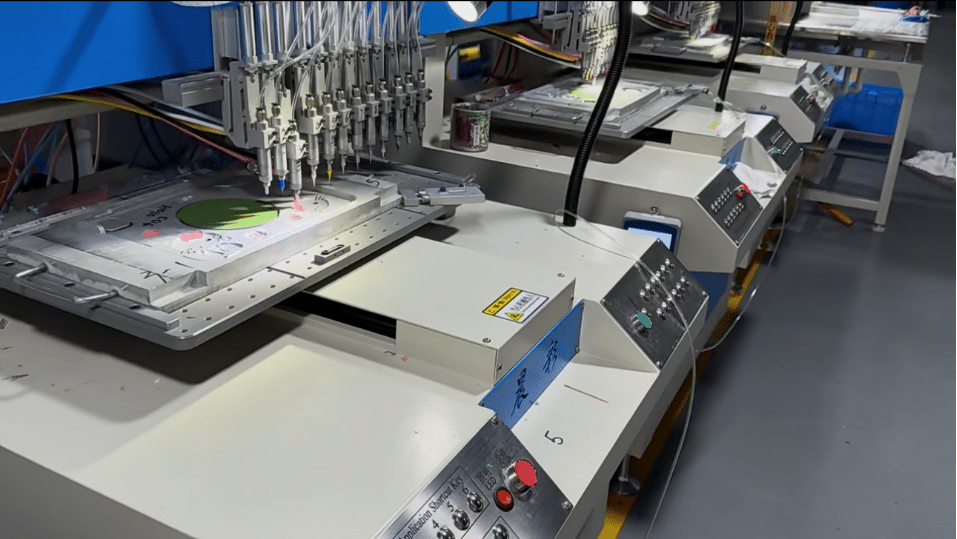

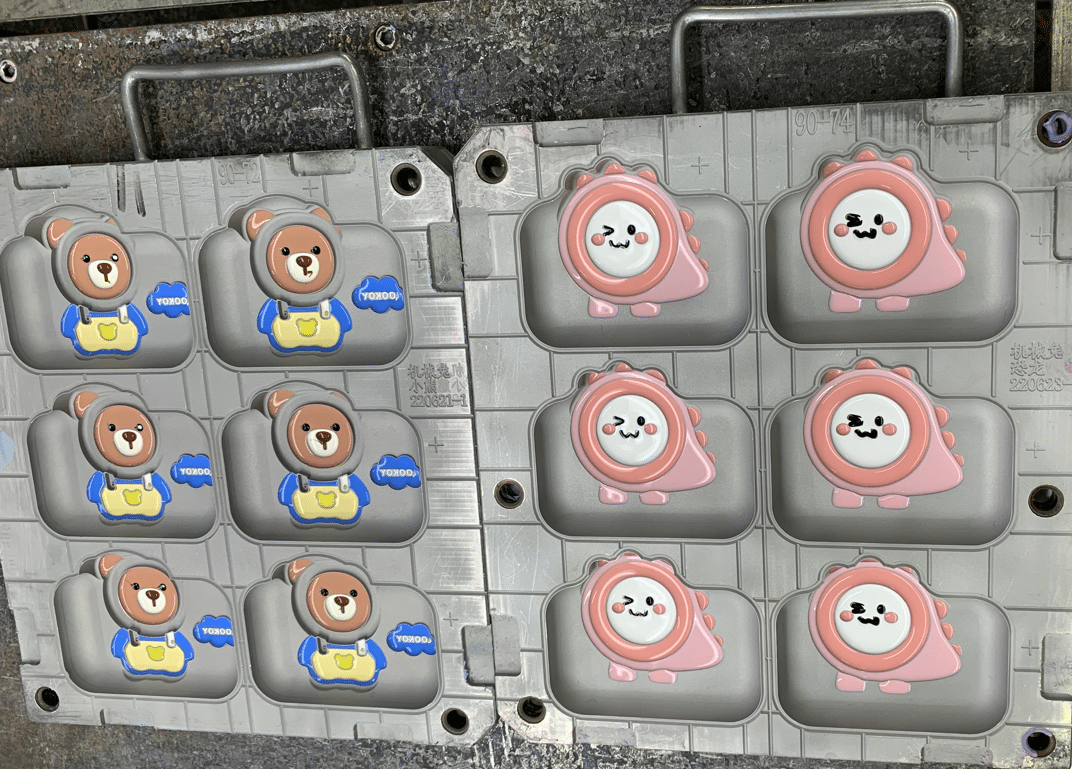

Silicone Dripping dispensing molding

Multi-Color Dripping Molding

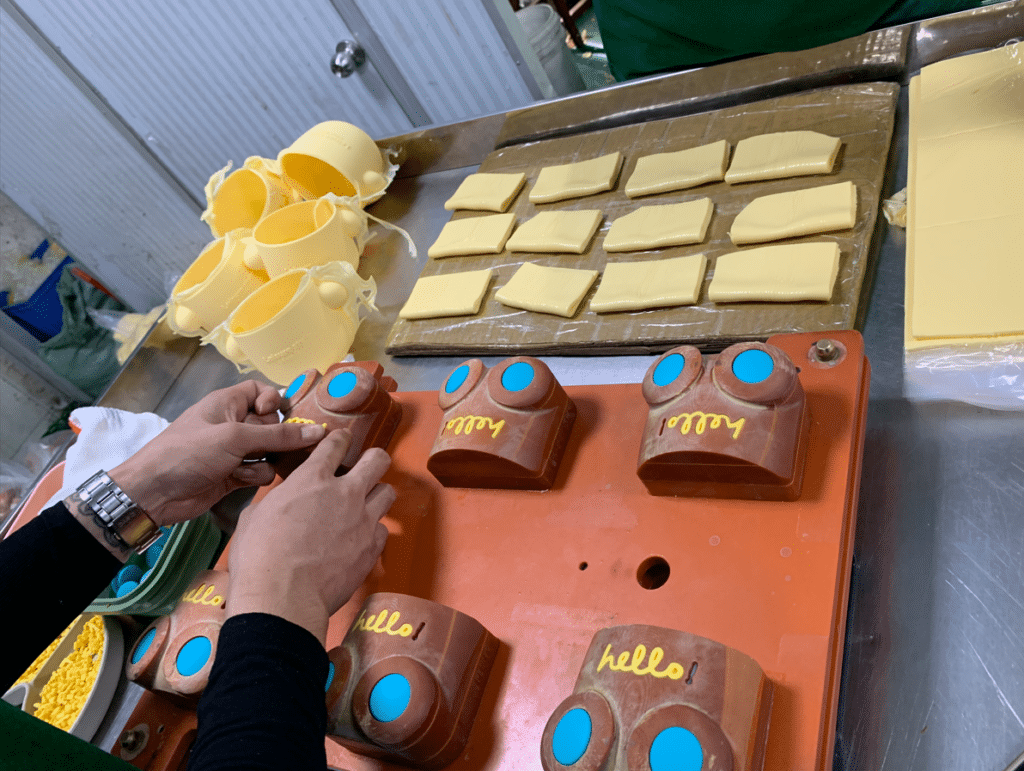

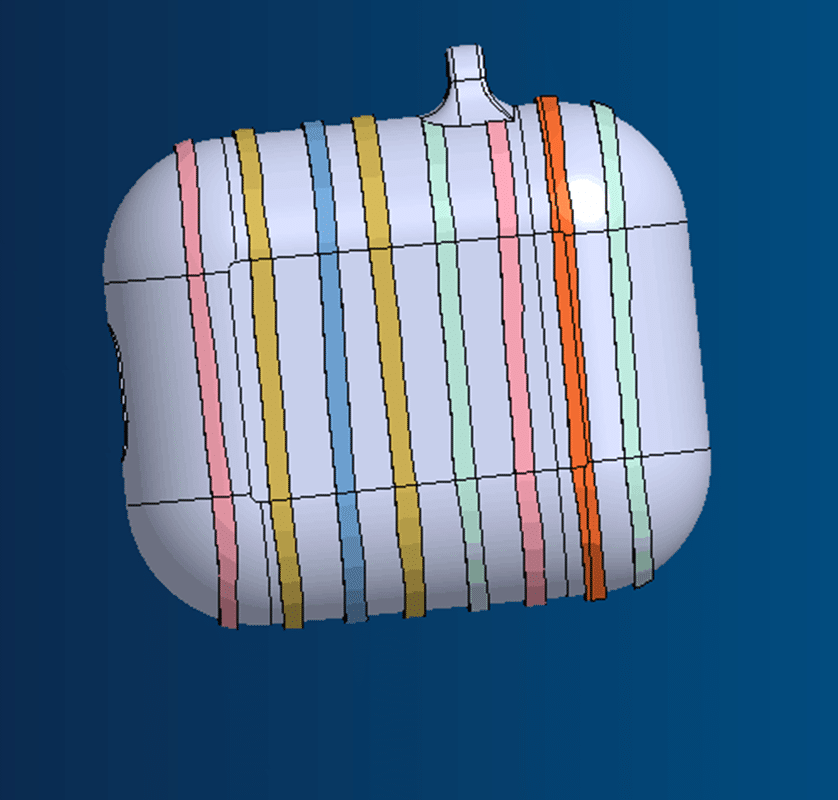

Need prepare silicone as the main material for dispensing molding, usually liquid silicone (LSR) and solid silicone, color paste, vulcanizer, and also need silicone vacuum machine and automatic dispensing machine. As this kind of molding have two kind of molding process. We also call them co-injection molding. Mixed L.S.R material dripping from the automatic dispensing machine first, then heat and curing. Put the solid silicone rubber material on and close the molds put them silicone vacuum machine Vulcanization molding.

The customization process for create your private silicone shower scrubber or body scrubber

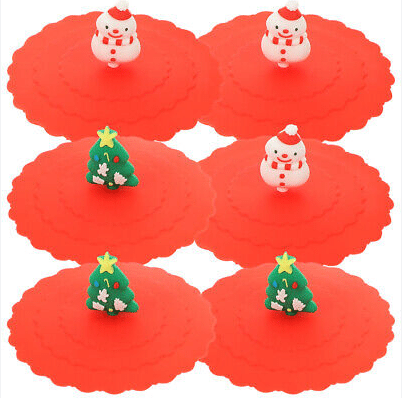

In Z.S.R, we can custom the silicone shower scrubber or body scrubber shape, size, color, pattern, brands, logo by silkscreen printing, full-color printing, or laser engraving for your silicone products, if you would like to custom your brands silicone shower scrubber or body scrubber contact Z.S.R.

Customizable Content:

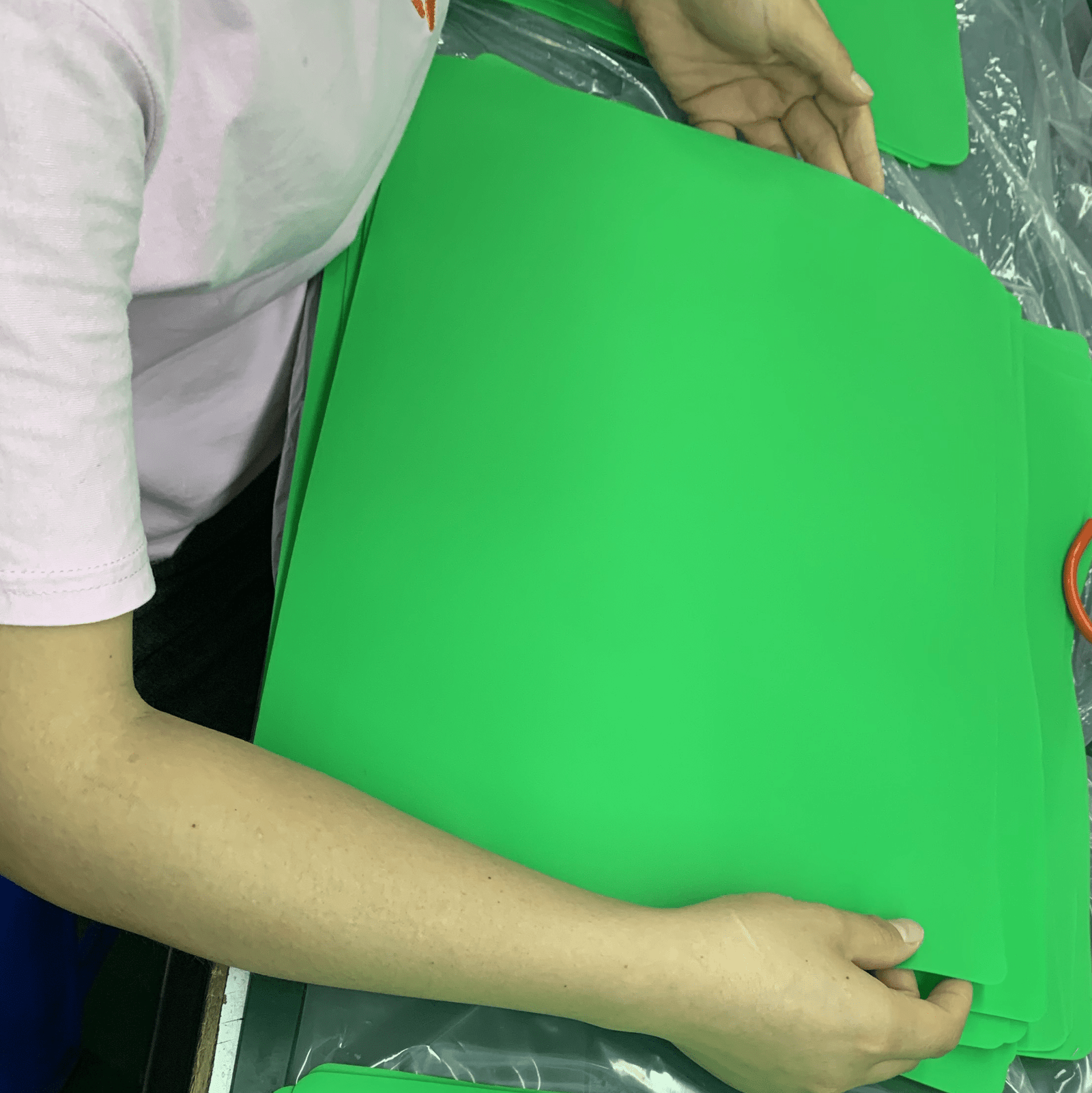

Appearance (shape, color): The silicone shower scrubber or body scrubber shape can be round, square or creative shape by developing the new tooling. The color can be white, blue, black or use the pantone book number to customized. You also can get mixed color, marble color or double colored, multi-colored appearance.

Material properties: You can customization the material with HTV material or LSR material. The hardness you can choice from 5-80 shore A, Translucent to highly transparent, Safety level from Food Grade to Medical grade, tensile properties from ordinary to high level).

Mold type: Steel, Copper or Al.

Molding method:LSR Injection molding, HTV compression molding, dripping molding.

Labeling: Logo on the tooling and get the logo products. We also can Screen Printing,Laser Engraving,Heat Transfer Printing your logo on the silicone shower scrubber or body scrubber already.

Packaging:zip bag, back card PET box, color box.

Shipping method: DHL, FedEx, Air shipping or Sea shipping.

How to create your silicone shower scrubber or body scrubber brand or start your silicone shower scrubber or body scrubber business?

1. Choose the design and style of the silicone molded products that you want to customize from Z.S.R’s existing designs. Or Starting with your new product idea to create your molded products, our engineers can proceed with the CAD/Stp/Step/X-T drawings just based on your sketches.

Our design and manufacturing engineers will work with your team to ensure designs meet processing requirements and can be produced consistently and cost-effectively. For your ODM or OBM project, we can sign an NDA non-disclosure agreement with you. It wards off any copycats that plagiarize your designs.

Design 3D structure of the silicone shower scrubber or body scrubber according to your idea .

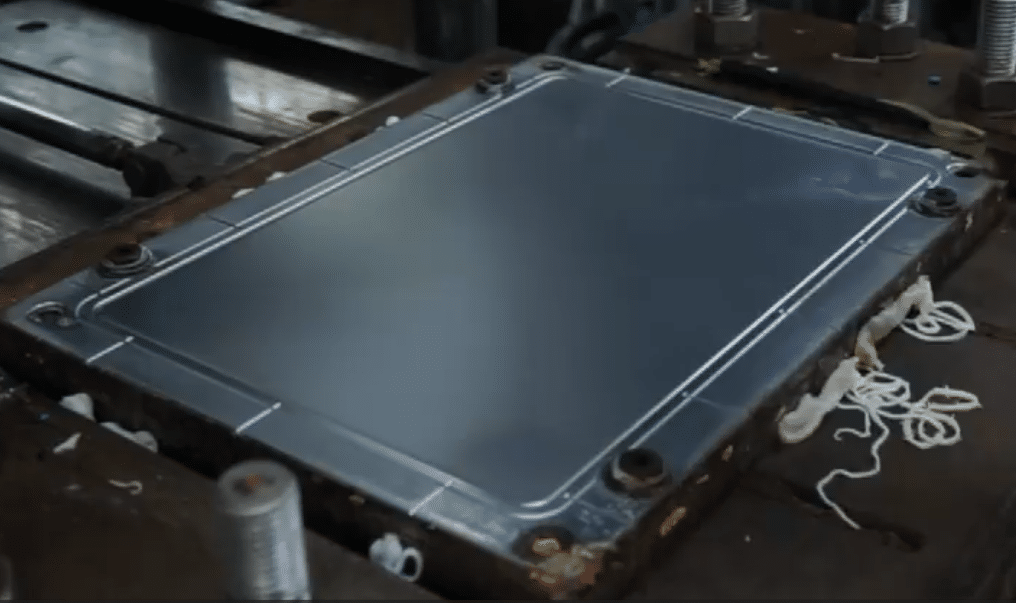

2. Z.S.R will make the prototype tooling to get the prototype to let you confirm. If all go through, we will make the mass production tooling for you and remake the samples for get your approved confirmation samples.Make the silicone shower scrubber or body scrubber tooling according to the silicone shower scrubber or body scrubber design requirements (Signal color or multi color) use the different metal, such as steel, copper or AL to ensure the accuracy and durability of the tooling.

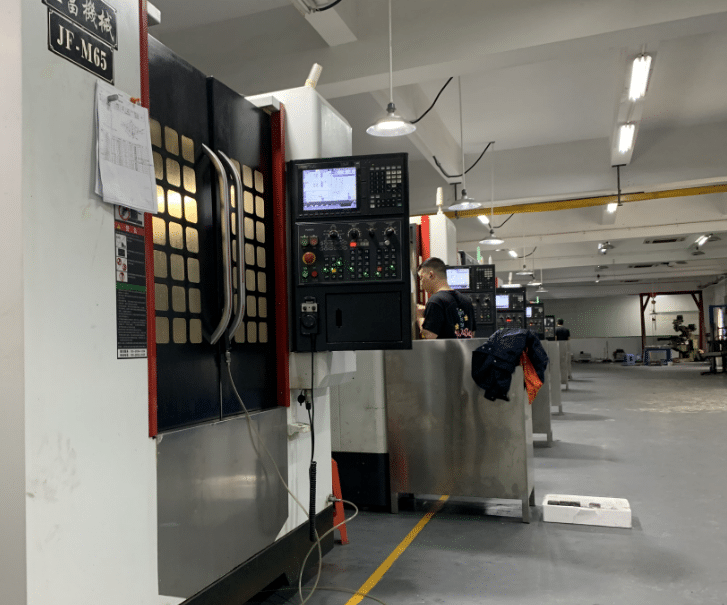

Z.S.R International Group (HONG KONG) CO., LIMITED in-house tool shop consists 6 sets of advanced CNC machining centers and 3 sets of EDM spark machines for tooling; So, we can make most of the silicone tooling and repair the silicone tooling in our factory to catch up your time needed.

3. Prepare the silicone raw silicone shower scrubber or body material: Raw silicone shower scrubber or body material are the key to silicone shower scrubber or body scrubbers’ products. Usually, Silicone shower scrubber or body scrubbers meet certain environmental protection standards, so silicone shower scrubber or body material are no exception. Normally, environmentally friendly Fumed silicone rubber is selected for customized processing, while many manufacturers use Precipitated silicone rubber for processing. Although the product is not greatly affected, it is still different Fumed silicone rubber from in quality after a long time. Mix the silicone color according to your silicone shower scrubber or body scrubber needed. Cutting the mixed silicone shower scrubber or body material in the correct weight.

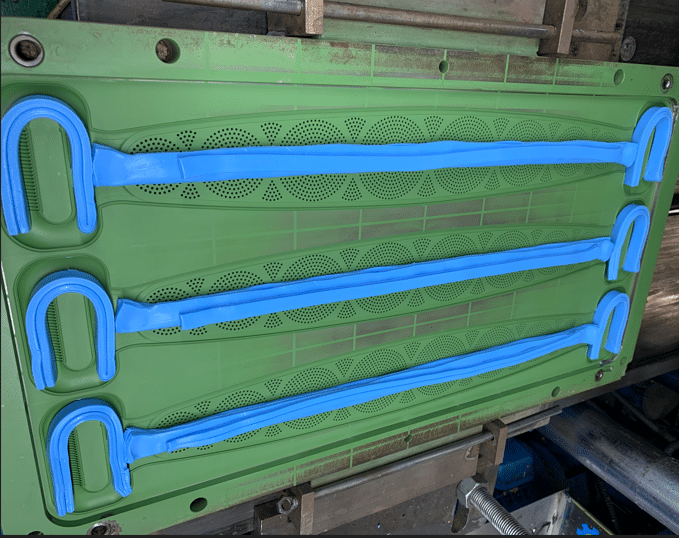

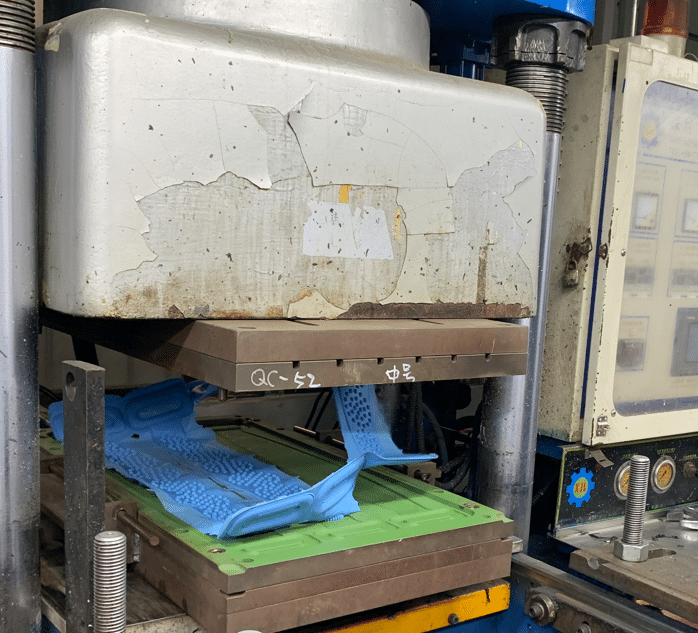

4. Feeding the prepared silicone mixed silicone shower scrubber or body material on-no silicone shower scrubber or body scrubberter Liquid siilcone rubber or solid siilcone rubber in to the mold.

5. Curing the silicone shower scrubber or body scrubber: The silicone silicone shower scrubber or body material is feeding into the mold after mixing, and the silicone silicone shower scrubber or body material is filled into the entire space of the mold through heating and pressure. The temperature, pressure and time control of the molding process directly affect the size, shape and quality of the product.

No silicone shower scrubber or body scrubberter the silicone shower scrubber or body scrubber was made by: Compression molding or silicone dripping molding or LSR molding.

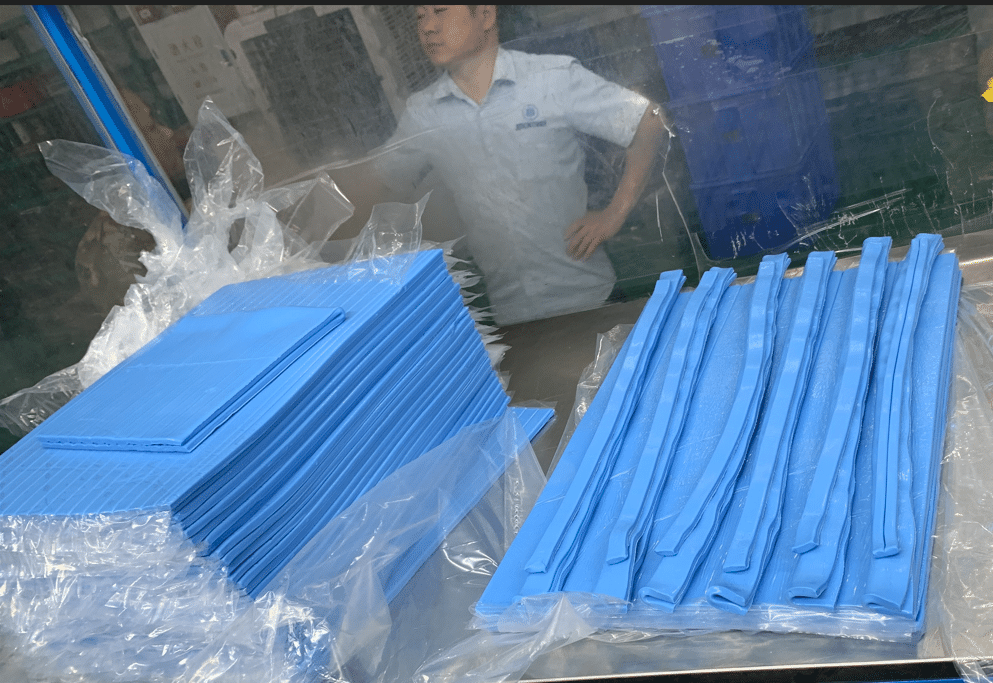

6. Demold: After the curing is completed, take the silicone shower scrubber or body scrubber product out of the mold.

7. QC the silicone shower scrubber or body scrubber: Quality inspection: Visually inspect the molded silicone shower scrubber or body scrubber to see if there is lack of silicone shower scrubber or body material, uncooked Ness, or impurities.

8. Post-processing: Carry out the silicone shower scrubber or body scrubber and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

9. Secondary vulcanization: Secondary vulcanization is a process that must be handled for any product that has passed the inspection. The main reason why infant silicone products have a certain smell is that they have not been subjected to Secondary vulcanization baking, and the catalyst of the raw silicone shower scrubber or body material of the products has not been emitted. At present, many silicone children’s product manufacturers basically handle it, but the time and temperature of the Secondary vulcanization treatment are different. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone shower scrubber or body scrubber may do not need this process.

.

10. LOGO or Pattern printing if needed: screen printing or laser engraving. Most of time, we put the silicone shower scrubber or body scrubber logo on the silicone tooling directly. Check the products branding service to know more.

11. Final Quality control and testing: After all the silicone shower scrubber or body scrubber making process finished, we will arrange the final QC for the silicone shower scrubber or body scrubber before the delivery.

12. Package and Warehouse: Z.S,R offer custom packaging solutions you need for all your product packaging. Our custom packaging includes paper boxes, PE/PVC boxes, printed labels, hangtags, barcode stickers, etc to protect the safety of the product during transportation and storage, while ensuring the safety and aesthetics of the product.

In Z.S.R, we manufacture the silicone shower scrubber or body scrubber according to the client’s design and idea. We try our best to deliver the quality silicone shower scrubber or body scrubber to our customer.

How much of the silicone shower scrubber or body scrubber?

From 0.99D-8.19USD/pcs depend on the design and structure and package

In Z.S.R, we custom the silicone shower scrubber or body scrubber shape, size, color, pattern and brands for your own silicone shower scrubber or body scrubber, if you would like to custom your brands silicone shower scrubber or body scrubber, contact Z.S.R.

Notice

When you buy the silicone shower scrubber or body scrubber, should pay attention to:

- Material and Certification: Silicone body scrubber usually consist of three parts: silicone material, bristles, and handles. You should choose a silicone body scrubber that meets your needs and is non-toxic and environmentally friendly to ensure safe use. lead, PVC-, and phthalates-free. Check whether the silicone shower scrubber or body scrubber product has a safety test certificate to ensure that it meets the relevant food safety standards. In China, silicone shower scrubber or body scrubber products can be checked for compliance with the limit requirements of GB 4806.11-2016 “National Food Safety Standard Food Contact Rubber Silicone shower scrubber or body material and Products”, while foreign products should be checked for US FDA certification, CPSIA certification or EU LFGB certification, etc. Food-grade silicone is preferred, IN USA -FDA Approved -silicone shower scrubber or body scrubber. The silicone shower scrubber or body scrubber should be 100% food-grade silicone raw silicone shower scrubber or body material to ensure safety. Ensuring that it complies with FDA and LFGB standards. Avoid choosing silicone shower scrubber or body scrubber made of ordinary plastics because they may release harmful substances.

- Cleaning effect: The cleaning effect of a silicone body scrubber depends on the density and hardness of the bristles. Choosing bristles with moderate density and appropriate hardness can better clean the skin while avoiding excessive skin irritation.

- Comfort: The silicone material should be soft and flexible to ensure that it does not cause damage to the skin during use. Especially for sensitive skin, it is more important to choose a soft silicone material.

- Portability: The silicone body scrubber should be designed to be small and lightweight, easy to carry and store. This ensures that it can be used conveniently when traveling or going out.

- Durability: The service life of a silicone body scrubber depends on its quality and manufacturing process. Choosing a good quality silicone body scrubber can extend its service life. However, it is still necessary to replace it in time according to needs.

- Price: Choose a suitable silicone body scrubber according to your budget. The prices of different brands and models vary greatly, and you can make a choice according to your needs and budget

When you would like to buy the silicone shower scrubber or body scrubber, you should comprehensively consider factors such as material, safety, silicone shower scrubber or body material, design, brand, cleaning and maintenance, and size to ensure a safe.

Conclusion

No matter you would like to create the silicone shower scrubber or body scrubber with your logo or design for sales, promotional or events. Our high-quality customize silicone shower scrubber or body scrubber are perfect for branding, souvenir, corporate gifts.

Z.S.R. customized branded silicone shower scrubber or body scrubber with added your logo, design pattern, text may be your good choices.

In Z.S.R, all the steps from raw silicone shower scrubber or body scrubber material selection to molding, curing, and quality control, each step plays a vital role in creating your silicone shower scrubber or body scrubber that meet safety standards and perform well in their intended applications.

Contact Z.S.R to brand your own silicone shower scrubber or body scrubber by contract manufacturing.

Related Article

How to create your molded silicone products?

How to create private silicone protector?

How to create private silicone trays?

How to create private silicone sleeves?

How to create private silicone plate?

How to create private silicone placemats?

How to create private silicone molds?

How to create private silicone mats?

How To Create Your Silicone Cups?

How To Create Your Silicone Cases?

How To Make silicone boots?

How To Make Silicone Lids?

How To Make Silicone Bowls?

How To Make Silicone Earbud/Earphone Cases?

How to Make Your Silicone Brushes/Scrubbers?

How to Make Silicone Caps: Materials, Tools, Equipment

How to Make Silicone Bags: A Comprehensive Guide from Material Selection to Finishing Touches

How to make air fryer silicone pots or silicone air fryer liner?

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.