How To Create Your Silicone Cases?

Silicone cases offer advantages such as high and low-temperature resistance (-40°C to 230°C), anti-slip and drop protection, and environmental friendliness.

Anti-Drop Protection

Silicone cases can absorb impact and reduce damage to devices when dropped. Suitable for devices prone to falling, such as smartphones and e-cigarettes.

- Smartphones: Silicone cases absorb impact, reduce damage from drops, and provide a good grip to prevent slipping.

- Tablets: Silicone cases provide all-around protection, and some designs include a stand function for watching videos or video conferencing.

- Laptops: Silicone cases are lightweight and durable, preventing surface scratches or impacts.

- Smartwatches: Silicone cases protect watch screens and casings from scratches and are comfortable for long-term wear.

- Earphones: Silicone protective covers prevent earphone wires from tangling and keep them neat.

- Electronic Cigarettes: Silicone protective covers absorb impact, prevent damage from drops, and provide a good grip.

- Electronic Equipment Buttons, Interfaces, Radiators, Batteries, Antennas, Displays, and Casings: Silicone protective covers offer dust and water resistance, extending the equipment’s lifespan.

Anti-Slip Design

Silicone material provides excellent grip, effectively preventing devices from slipping. Suitable for devices that require a secure hold, such as smartphones, tablets, and laptops.

Waterproof and Dustproof

Some silicone cases feature a sealed structure, providing a certain degree of waterproof and dustproof protection. Suitable for electronic devices that require such protection, such as interfaces and displays.

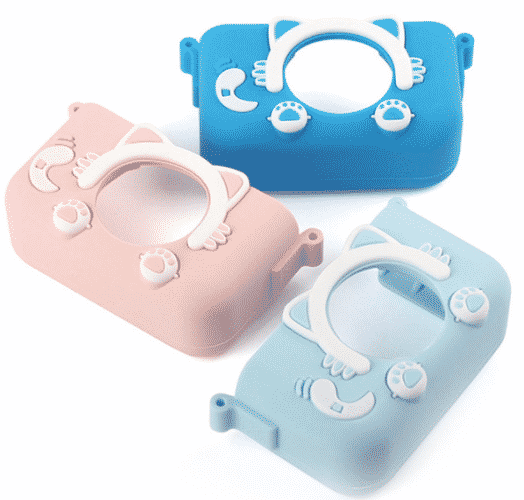

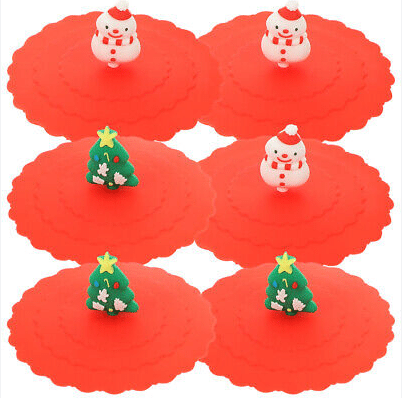

Aesthetic Decoration

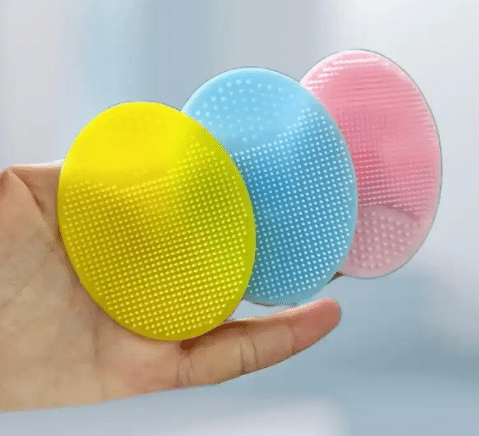

Silicone cases come in various colors and customizable shapes, enhancing the device’s appearance and showcasing personality. Suitable for users who prioritize aesthetics and personalization.

Portability

Silicone material is lightweight and easy to carry. Suitable for small devices like earphones and e-cigarettes.

Maternal and Child Products

Silicone material is often used to make pacifiers, bottle protective covers, teethers, etc., due to its softness and elasticity. It is safe, non-toxic, and provides a comfortable touch for babies.

Silicone cases are widely used in electronics (e.g., AirPod cases, iPhone cases), children’s products, homeware, and medical or industrial areas.

What Is a Silicone Case?

A silicone case is a protective cover or shell made of silicone material, typically formed through vulcanization compression molding, liquid injection molding, or drip molding of silicone raw materials. It is characterized by environmental friendliness, safety, and drop resistance.

Silicone cases are generally soft, durable, shatter-resistant, environmentally friendly, scratch-proof, and easy to clean. Crafted from flexible and shock-absorbent material, silicone cases offer full-edge protection against life’s unpredictable moments.

Silicone cases vary according to their characteristics and application scenarios:

- Silicone Medical Device Cases: Ideal for handheld scanners, instruments, printers, POS devices, thermal imaging cameras, and testing equipment. Using protective cases saves customers money by preventing potential product damage.

- Silicone iPad Cases, Mobile Phone Cases, iPad Covers, Earbuds Silicone Cases, and Other Electronic Products: Includes silicone pencil cases, etc.

What Are the Advantages of Silicone Cases?

- Environmental Protection and Safety: Silicone cases use environmentally friendly gas-phase silica gel, which has good chemical stability. It does not react with any acid or alkali except in extreme cases (caustic alkali and hydrofluoric acid). It is non-toxic and odorless, making it suitable for high-safety products like baby pacifiers and silicone bottles.

- Good Cushioning Performance: Provides effective shock absorption when dropped.

- Durability: The material is stable and not easily worn.

- Good Waterproof Performance: Offers a certain level of waterproofing.

- Strong Protection: Effectively prevents device damage from accidental drops.

- Versatility: Includes anti-slip, waterproof, and dustproof functions.

- Aesthetics: Available in various colors and customizable shapes to enhance device appearance.

Z.S.R offers various custom silicone cases in different shapes and colors for industries such as baby products, homeware, electronics, and promotional items.

Materials, Tools, Equipment

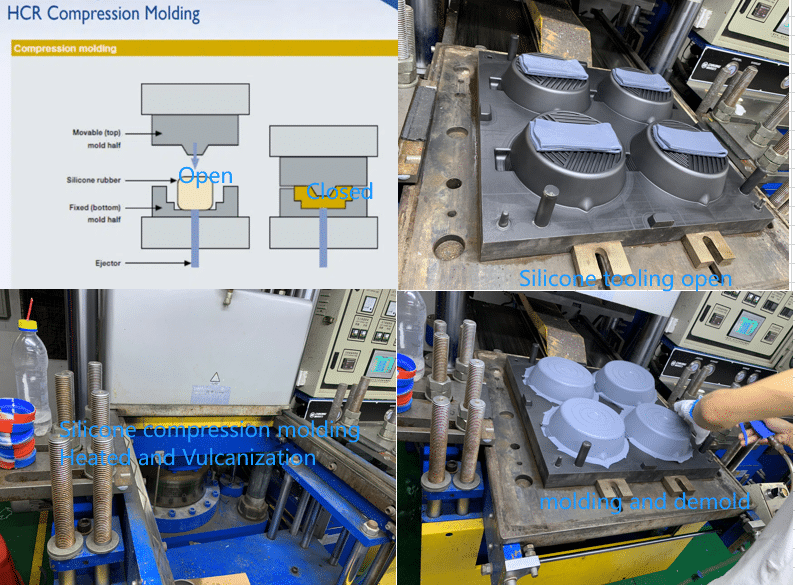

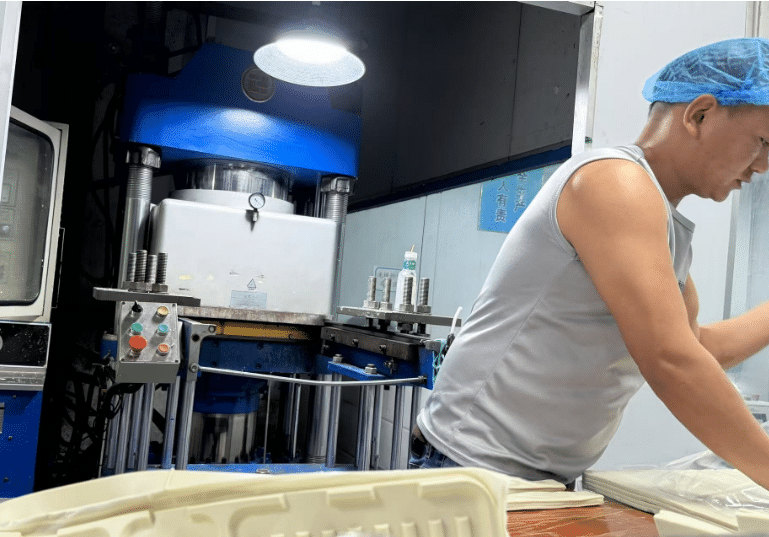

Depending on the silicone case manufacturing process, there are five methods: silicone rubber compression molding, LSR injection molding, silicone drip molding, silicone extrusion molding, and silicone calendaring molding. At Z.S.R, we have the capacity for three molding processes for silicone cases. Different molding processes require different materials, tools, and equipment.

Silicone compression molding

Silicone Compression Molding

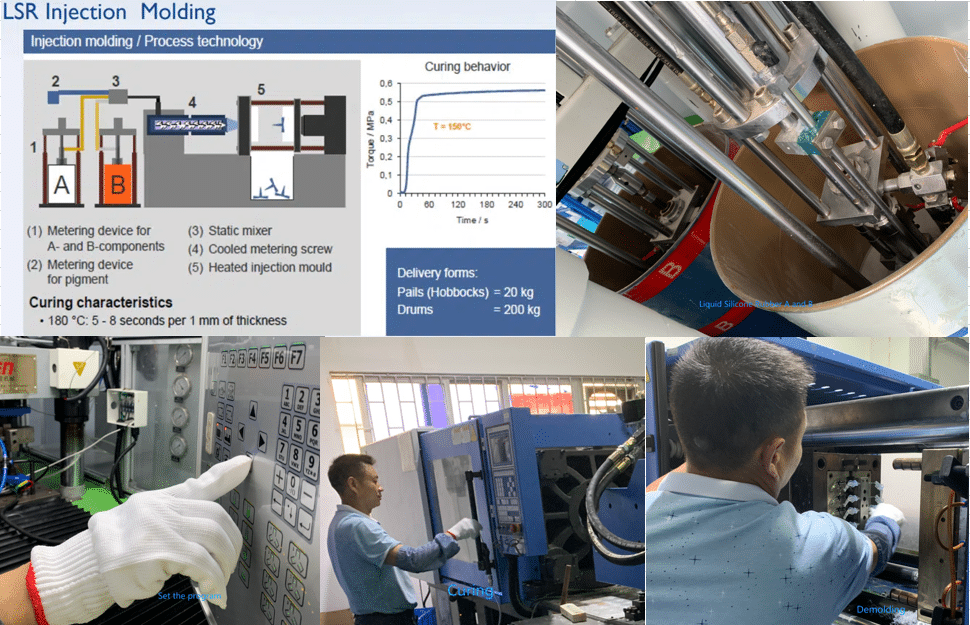

L.S.R injection molding

Liquid Silicone Rubber (LSR) Injection Molding

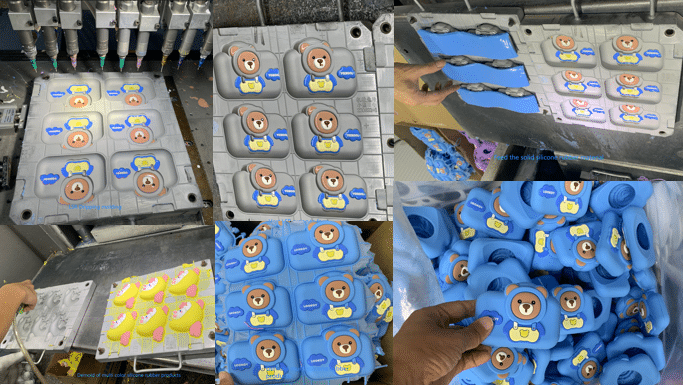

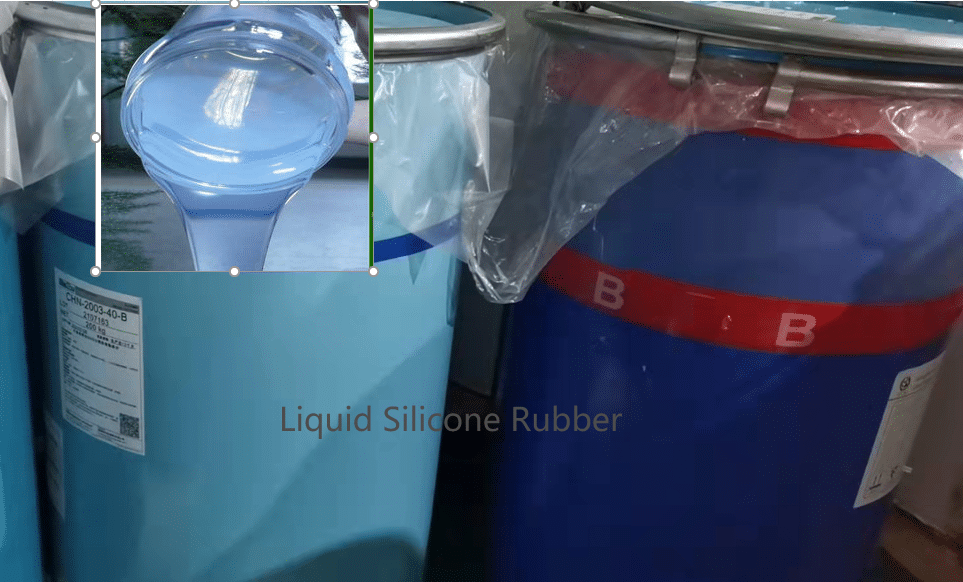

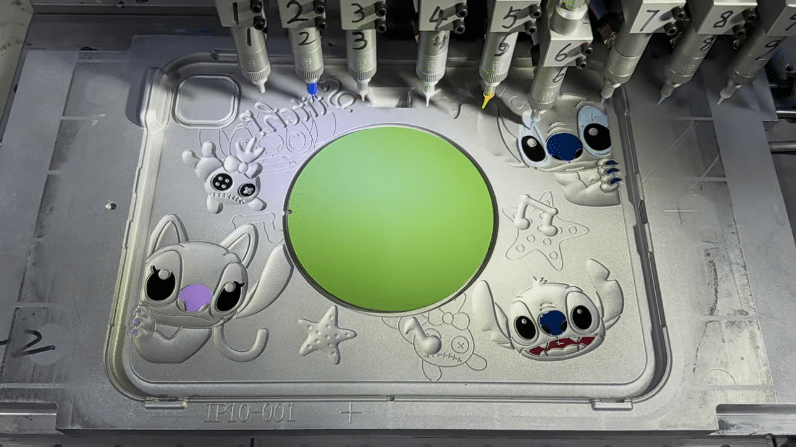

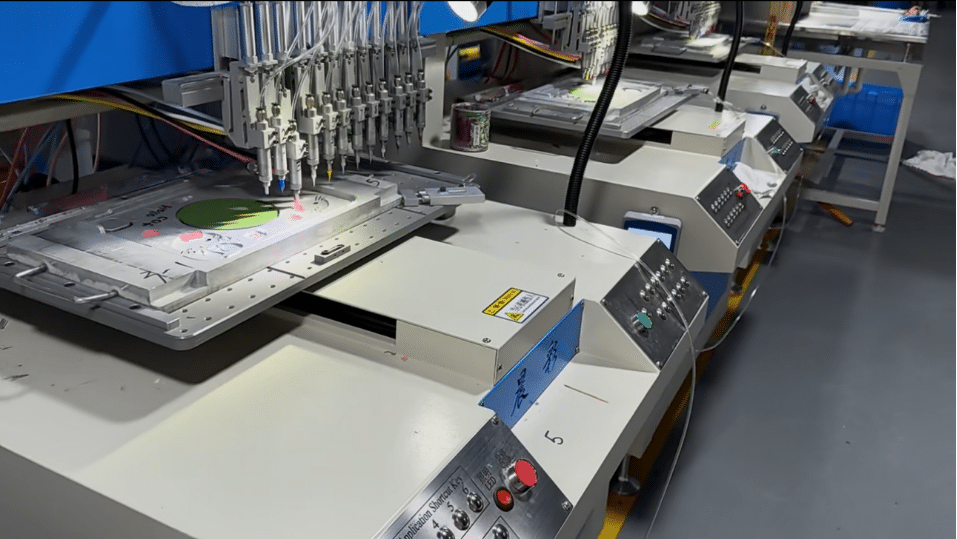

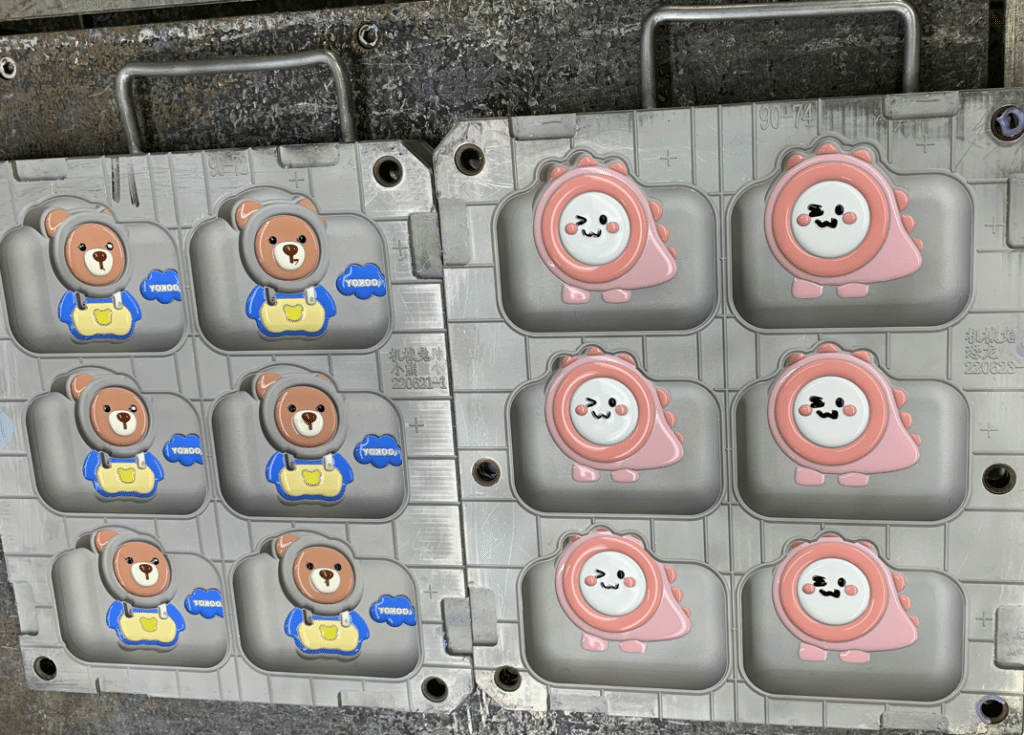

Silicone Dripping dispensing molding

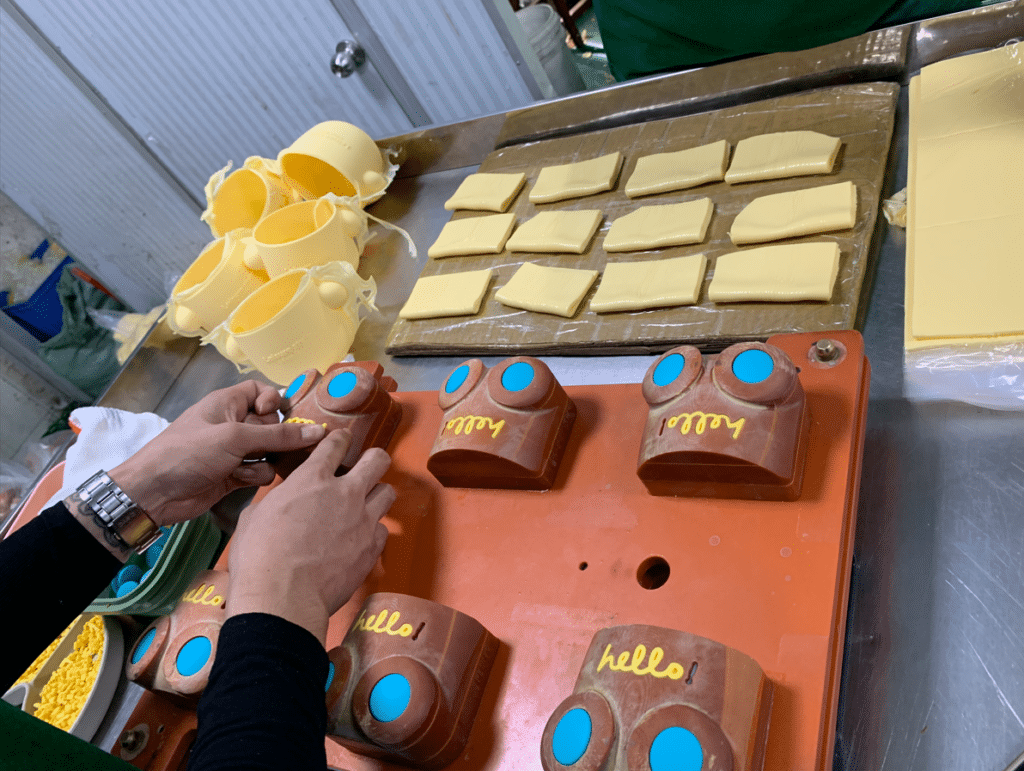

Multi-Color Dripping Molding

Need prepare silicone as the main material for dispensing molding, usually liquid silicone (LSR) and solid silicone, color paste, vulcanizer, and also need silicone vacuum machine and automatic dispensing machine. As this kind of molding have two kind of molding process. We also call them co-injection molding. Mixed L.S.R material dripping from the automatic dispensing machine first, then heat and curing. Put the solid silicone rubber material on and close the molds put them silicone vacuum machine Vulcanization molding.

Customization Process for Creating Your Private Silicone Cases

In Z.S.R, we can custom the silicone cases shape, size, color, pattern, brands, logo by silkscreen printing, full-color printing, or laser engraving for your silicone products, if you would like to custom your brands silicone cases contact Z.S.R.

Customizable Content

- Appearance (Shape, Color): Shapes can be round, square, or creative designs via new tooling. Colors include white, blue, black, or Pantone-matching. Mixed, marble, double-colored, or multi-colored appearances are available.

- Material Properties: Choose HTV or LSR materials. Hardness ranges from 5-80 Shore A, translucent to highly transparent, food-grade to medical-grade safety levels, and varying tensile properties.

- Mold Type: Steel, copper, or aluminum.

- Molding Method: LSR injection molding, HTV compression molding, or drip molding.

- Labeling: Logos can be incorporated into the tooling or added via screen printing, laser engraving, or heat transfer printing.

- Packaging: Zip bags, back card PET boxes, or color boxes.

- Shipping Method: DHL, FedEx, air shipping, or sea shipping.

How to Create Your Silicone Case Brand or Business

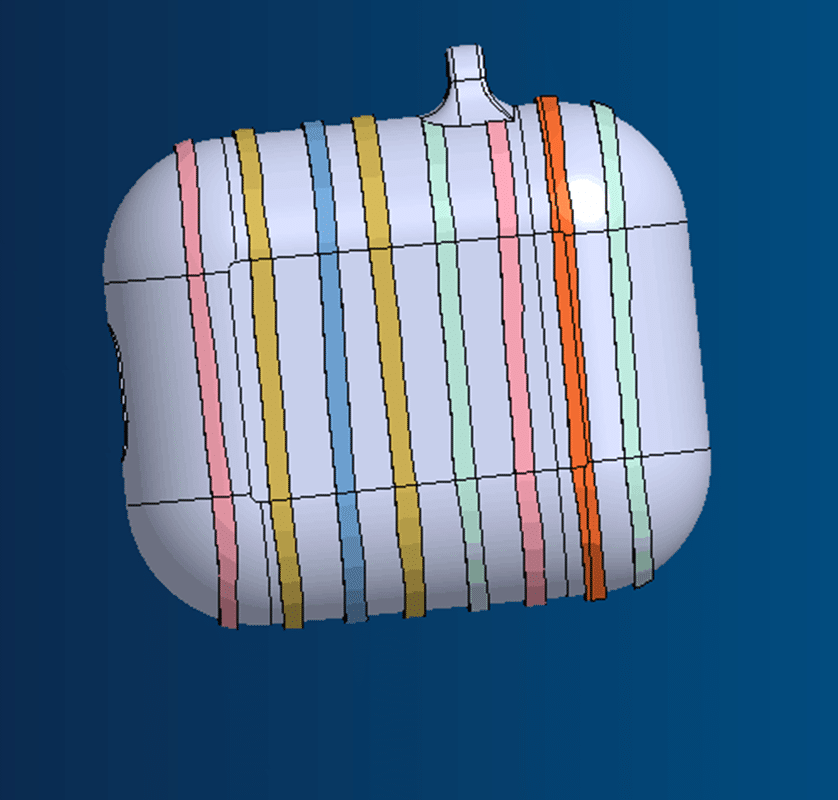

1. Design 3D structure of the silicone case according to your idea

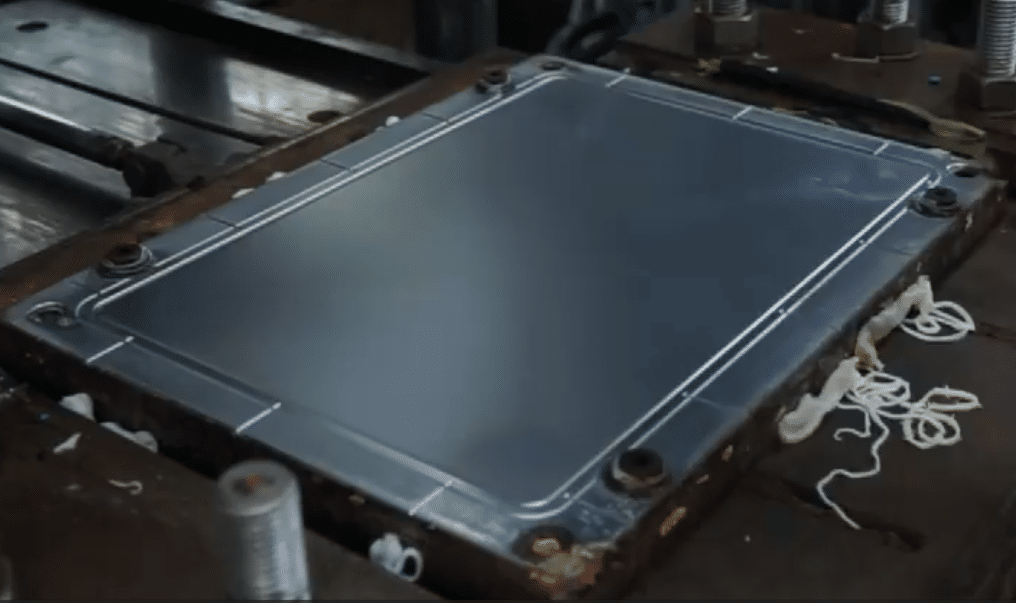

2. Make the silicone case tooling according to the silicone case design requirements (Signal color or multi color) use the different metal, such as steel, copper or AL to ensure the accuracy and durability of the tooling.

Z.S.R International Group (HONG KONG) CO., LIMITED in-house tool shop consists 6 sets of advanced CNC machining centers and 3 sets of EDM spark machines for tooling; So, we can make most of the silicone case tooling and repair the silicone case tooling in our factory to catch up your time needed.

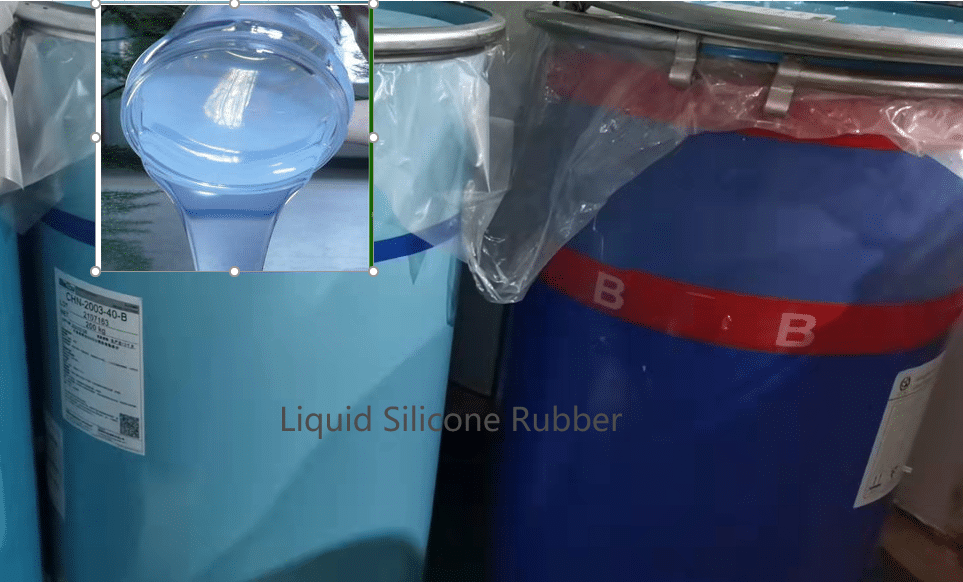

3. Prepare the silicone case raw material: Raw silicone material are the key to silicone case’s products. Usually, silicone cases meet certain environmental protection standards, so silicone case material are no exception. Normally, environmentally friendly Fumed silicone rubber is selected for customized processing, while many manufacturers use Precipitated silicone rubber for processing. Although the product is not greatly affected, it is still different Fumed silicone rubber from in quality after a long time. Mix the silicone color according to your silicone case needed. Cutting the silicone case material in the correct weight. The color matching principle of the silicone raw materials used in silicone cases is basically the same as the color matching principle in art painting. The white translucent silicone raw materials are combined with the addition of vulcanizers by adding color pastes of corresponding color proportions into them to mix and knead to obtain the corresponding required color. The color matching color is generally based on the international Pantone color card, namely PANTONE color or actual color samples.

4. Feeding the prepared silicone cases mixed material on-Feeding the silicone case material no matter the Liquid silicone rubber or solid silicone rubber in to the mold.

5. Curing the silicone case: The silicone cases material is feeding into the mold after mixing, and the silicone cases material is filled into the entire space of the mold through heating and pressure. The temperature, pressure and time control of the molding process directly affect the size, shape and quality of the silicone cases.

No matter the silicone case was made by: Compression molding or silicone dripping molding or LSR molding.

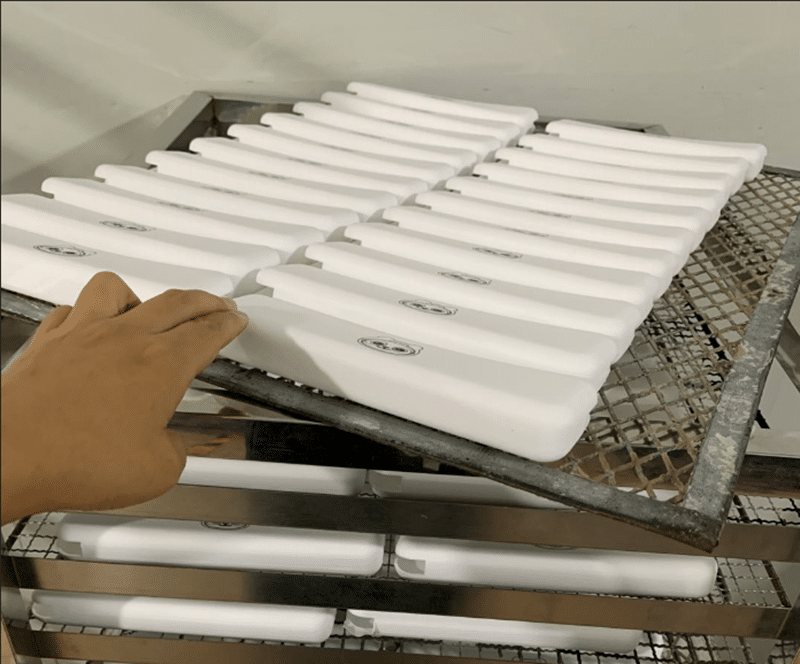

6.Demolding: After the curing is completed, take the silicone case product out of the mold.

7.QC the silicone case: Quality inspection: Visually inspect the molded silicone case to see if there is lack of silicone case material, uncooked Ness, or impurities

8. Post-processing: Carry out the silicone case and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

9. Secondary vulcanization: Secondary vulcanization is a process that must be handled for any product that has passed the inspection. The main reason why silicone cases have a certain smell is that they have not been subjected to Secondary vulcanization baking, and the catalyst of the raw silicone cases material of the products has not been emitted.

At present, many silicone product manufacturers basically handle it, but the time and temperature of the Secondary vulcanization treatment are different. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone case may do not need this process.

10. LOGO or Pattern printing on the silicone cases if needed: screen printing or laser engraving. Most of time, we put the silicone case logo on the silicone tooling directly. Check the products branding service to know more.

11. Final Quality control and testing: After all the silicone case making process finished, we will arrange the final QC for the silicone case before the delivery.

12. Package and Warehouse: Z. S. R offer custom packaging solutions you need for all your silicone case packaging. Our custom packaging includes paper boxes, PE/PVC boxes, printed labels, hangtags, barcode stickers, etc to protect the safety of the silicone case during transportation and storage, while ensuring the safety and aesthetics of the silicone case.

In Z.S.R, we manufacture the silicone case according to the client’s design and idea. We try our best to deliver the quality silicone case to our customer

Notice

When purchasing silicone cases, consider the following:

- Material and Certification: Ensure the silicone case is non-toxic, environmentally friendly, and free of lead, PVC, and phthalates. Check for safety test certificates, such as GB 4806.11-2016 (China), FDA (USA), CPSIA, or LFGB (EU). Food-grade silicone is preferred.

- Choose a Reliable Brand: Purchase from reputable brands to avoid safety hazards.

- Thickness and Protection: Silicone phone cases are typically thicker, offering better drop and collision protection.

- Feel and Durability: Liquid silicone cases feel smooth, rebound quickly, and do not yellow or discolor over time.

- Overall Considerations: Consider material, safety, brand, function, and size to ensure safe use.

Conclusion

Whether you want to create silicone cases with your logo or design for sales, promotions, or events, Z.S.R’s high-quality customized silicone cases are perfect for branding, souvenirs, and corporate gifts.

Z.S.R’s customized branded silicone cases with your logo, design pattern, or text are excellent choices.

At Z.S.R, every step—from material selection to molding, curing, and quality control—plays a vital role in creating silicone cases that meet safety standards and perform well in their intended applications.

Contact Z.S.R to brand your own silicone cases through contract manufacturing.

Related Article

How to create your molded silicone products?

How to create private silicone protector?

How to create private silicone trays?

How to create private silicone sleeves?

How to create private silicone shower scrubber or body scrubber?

How to create private silicone plate?

How to create private silicone placemats?

How to create private silicone molds?

How to create private silicone mats?

How To Create Your Silicone Cups?

How To Make silicone boots?

How To Make Silicone Lids?

How To Make Silicone Bowls?

How To Make Silicone Earbud/Earphone Cases?

How to Make Your Silicone Brushes/Scrubbers?

How to Make Silicone Caps: Materials, Tools, Equipment

How to Make Silicone Bags: A Comprehensive Guide from Material Selection to Finishing Touches

How to make air fryer silicone pots or silicone air fryer liner?

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.