The Silicone Material Differences: LFGB food grade Silicone

Silicone products are becoming more and more popular. Silicone products are resistant to high and low temperatures and can be used over a wide range of temperatures. The conventional temperature range of -40 ~ 230 degrees within the long-term use. They are also soft and comfortable, environmentally friendly, non-toxic, and degradable.

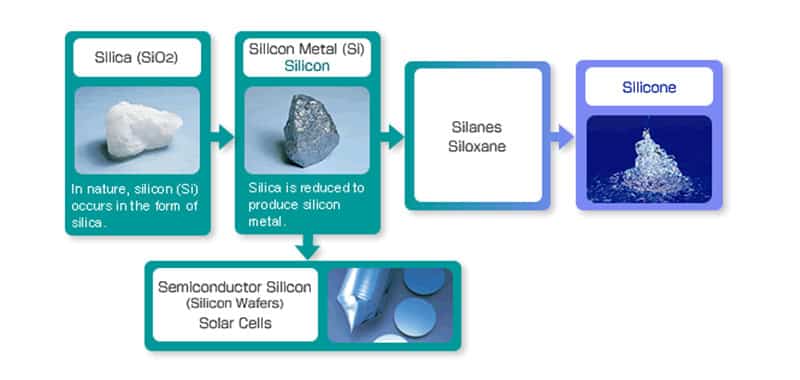

What is the silicone material made of?

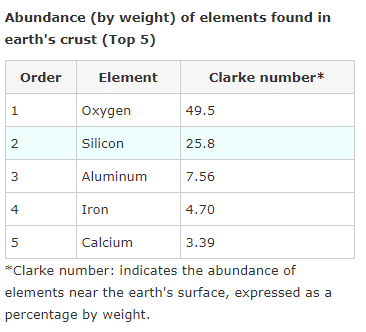

See the below of silicone chemical properties:

The different silicone products should be with different materials, production processes and quality requirements.

Would you like to know the difference between them?

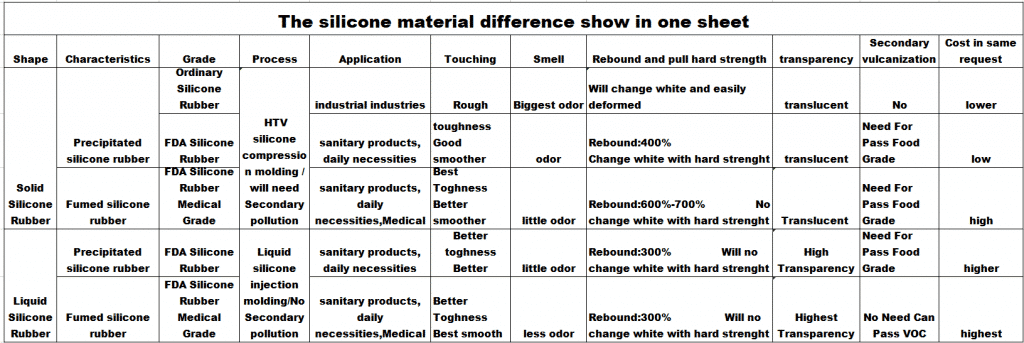

Please see the following sheet to get rough information for the difference in the silicone material.

Material characteristics

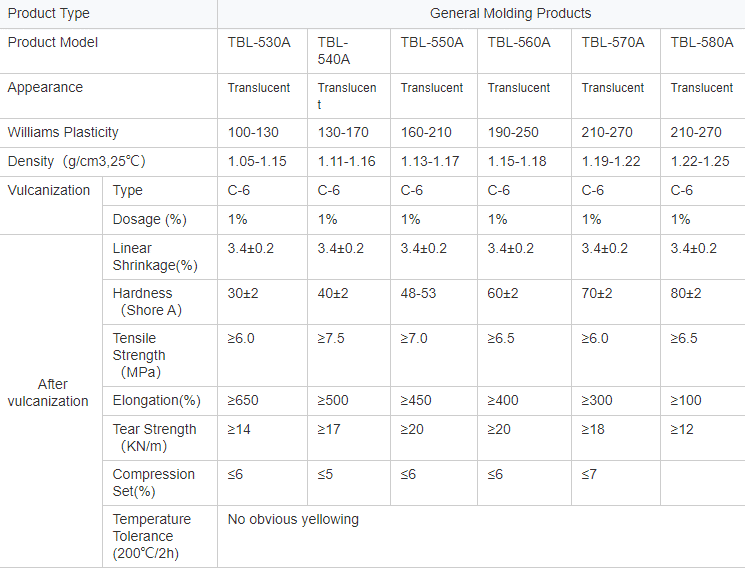

Physical properties.

There are two kinds of silicone material.

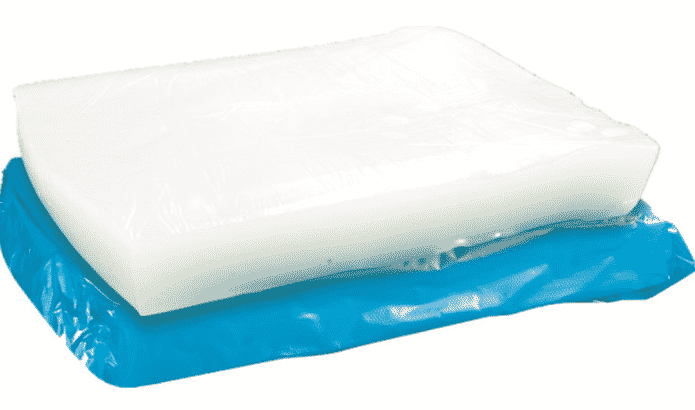

One is HTV Solid silicone.

A: Precipitated silicone rubber.

- Ordinary Silicone Rubber.

- Food Grade Silicone Rubber.

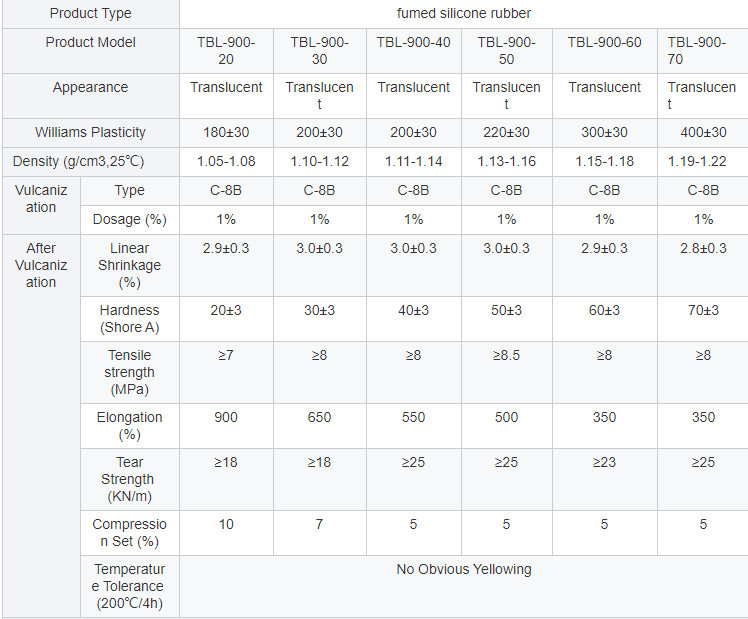

B: Fumed silicone rubber property.

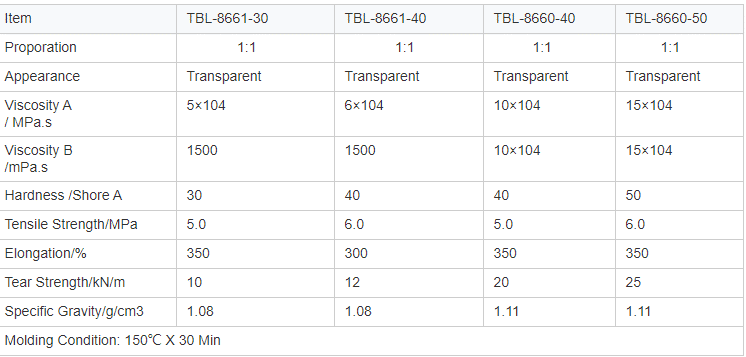

Another one is LSR Silicone Rubber.

A: Precipitated silicone rubber.

B: Fumed silicone rubber.

More About Food Grade Silicone

A: Precipitated silicone rubber property

The hardness range of this series is 30-80A, with heat resistance, translucent, good processability, easy demolding and good tear strength, etc. Products are generally used to make protective sleeves as well as food contact applications, automotive parts, rollers, household appliance parts and other products.

a1:Ordinary Silicone Rubber.

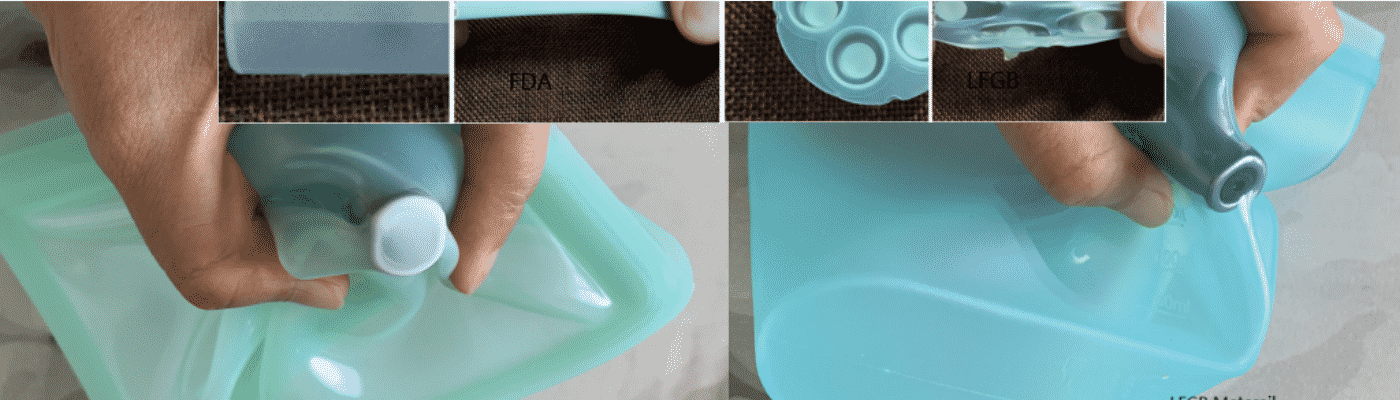

a2:FDA Silicone Rubber :Translucent and can pass FDA( Food & Drug Administration standard)approved.(Food Grade Silicone widely used in USA and international).

FDA testing method and Report.

B: Fumed silicone rubber property

One is Liquid silicone rubber:

The hardness range of this series is 20-70 SHA, with excellent resistance to high and low temperature performance(from -50℃ to +200℃), weather resistance, electrical performance, etc.

Products are widely used in electronics and electrical appliances, suitable for all kinds of keyboard, sundries, electrical wire&cable, tube, general O-ring, gaskets, seals,etc.

Translucent and able to meet the requirements of LFGB food grade.( mainly for Europe)

msds-fumed-silicone-rubber.pdf

B1:LFGB testing Method and Report.

The Liquid Silicone Rubber property

From the above information, you can see that:

The FDA (Food and Drug Administration) is standard in America( US FDA is internationally applied.) LFGB is standard mainly for Europe, Silicone products that pass either one of these tests are safe for human use. In terms of pricing, products in LFGB standard will be more expensive than FDA standard, so FDA is more widely used.

The difference between LFGB and FDA lies on the different way of testing method, and LFGB is more comprehensive and more strict.

Making Process

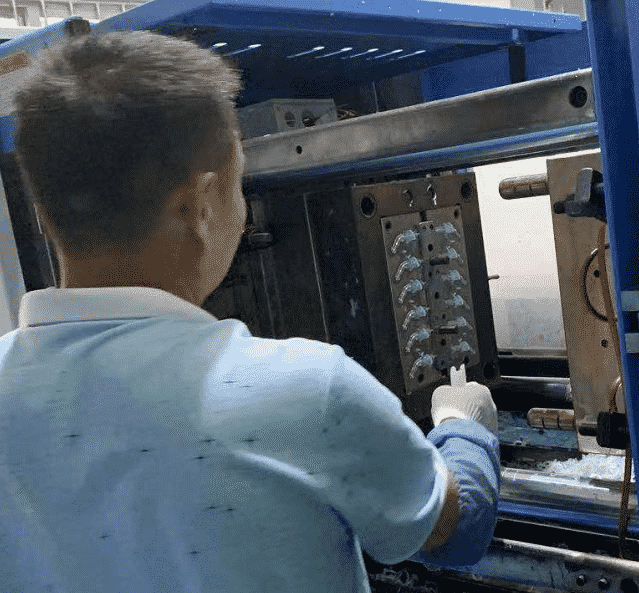

A: We usually use the HTV silicone compression molding when use solid silicone.

B: We use Liquid silicone injection molding when use the liquid silicone rubber.

Learn More About Silicone Molding Method And Process

Application difference

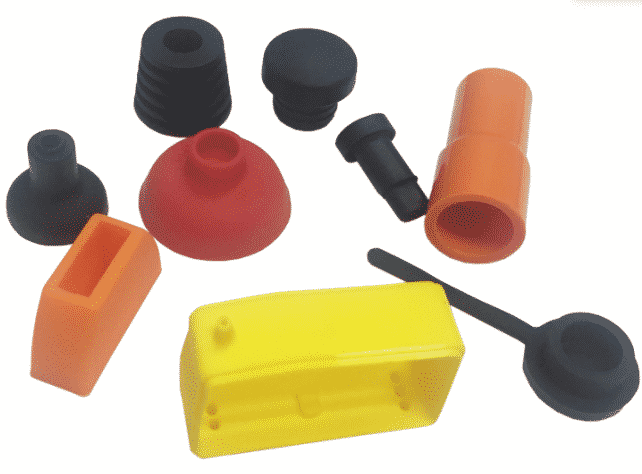

Ordinary Silicone:Widely use in international.

It is widely used in Some accessories for machinery, electronics, automobiles and agro-industrial industries.

Food Grade Silicone:Widely used in USA and international.fda-test-report.pdf

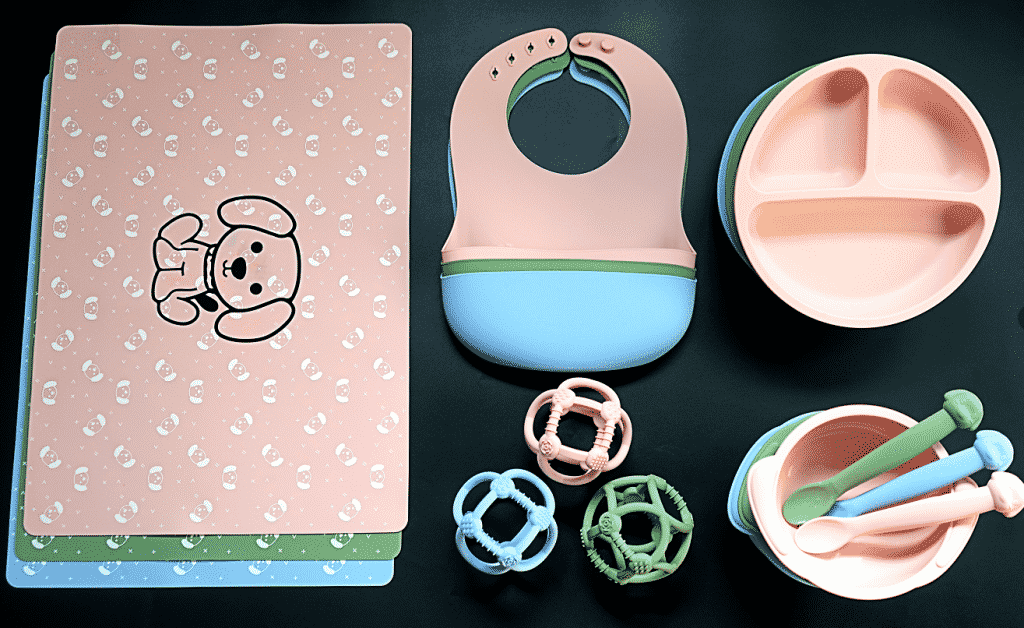

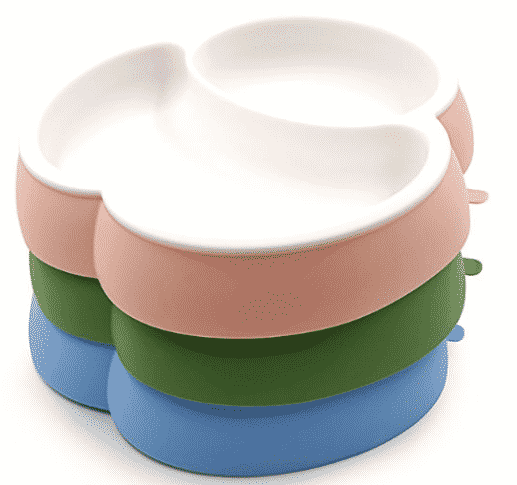

It is widely used in medical and sanitary products, daily necessities (such as silicone kitchenware, silicone gifts, etc.), baby products and other fields that require high levels of safety and environmental protection.

LFGB food grade:Widely use in Europe.lfgb-test-report.pdf

It is widely used in medical and sanitary products, daily necessities (such as silicone kitchenware, silicone gifts, etc.), baby products and other fields that require high levels of safety and environmental protection.

Liquid Silicone Rubber:Widely use in international

It is widely used in health-care manufacturing, automotive component manufacturing, electronics and consumer products, gaskets and other hardware.

Especially in high volumes needed.

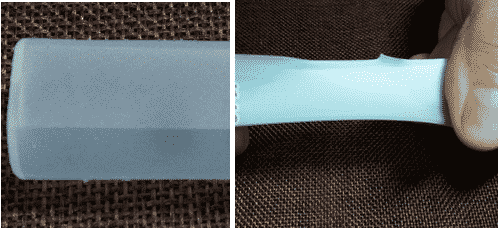

Touching difference

Ordinary silicone products are easily deformed and rough to the touch

The Food grade silicone has very good toughness and elasticity.fda-test-report.pdf, lfgb-test-report.pdf

The hand feel will be smoother.

Smell difference

Ordinary silicone products have a big smell.

The Food Grade Silicone also have a little odor, which is because the production process does not affect the quality, safety, and other issues, and the odor will be automatically eliminated after a period of time

The LSR silicone rubber smell is better than solid silicone rubber.

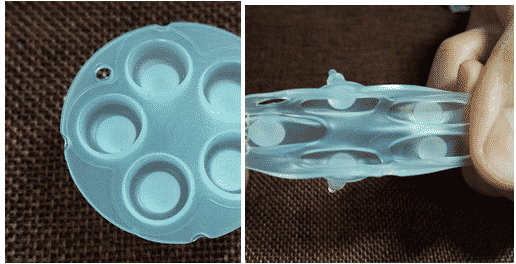

Rebound and pull hard strength difference

A:Precipitated silicone rubber

Rebound:400%

Pull hard strength:

This method is very simple.

Take a place in the silicone product and pull hard. If there is white, it is precipitated silicone rubber(Ordinary Silicone Rubber and FDA Silicone Rubber. )

B:Fumed silicone rubber

Rebound:600%-700%

Pull hard strength

If there is no white, it is LFGB food grade silicone.

Cost difference

Precipitated silicone rubber-made products. The raw material price is low. Ordinary silicone is the lowest. The FDA silicone is a little higher.

Fumed silicone rubber-made products. The raw material price is higher.

The Fumed Silicone material is more expensive than Precipitated silicone rubber products in production and manufacturing. It can pass ‘LFGB’ testing which is the toughest of all standards – this type of silicone material must pass more intensive testing, is of a better quality and is more expensive. It is also known as ‘Platinum Silicone’

The LSR products cost with high volumes will be similar like Fumed Silicone material. (LFGB silicone material)

ZSR Group,all of our products include the Silicone baby products,Silicone Beauty&Health-care, Silicone Pets, Silicone Consumer Electronic Protective Cover,Silicone Housewares Products, Silicone Promotional Gifts all made by Food Grade Silicone material and LFGB silicone material.

Conclusion

From the above differences, we can see there are two kinds of silicone material in shape.

Solid and Liquid.

- They need use different making process:

- HTV compression molding

- Liquid silicone rubber injection molding

Both FDA & LFGB approved silicone is considered all Food Grade Silicone and food safe. Silicone that has passed LFGB testing is definitely a better quality silicone resulting in greater durability and less foul silicone odour and taste.

Manufacturers will use different quality silicone material depending on their customer’s requirements. i.e. whether they require FDA or LFGB approved silicone fda-test-report.pdflfgb-test-report.pdf– which will depend on where the customer plans to sell their silicone products and also to what level of quality they want to offer their customers.

Any Silicone products or Silicone project need technical support, you could buy custom Silicone products at ZSR Group. ZSR Group has rich experience in producing Silicone products with FDA or LFGB Approved standard.We have the FDA register list number is 3011147430.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.