What is liquid silicone rubber (LSR)

Liquid silicone rubber (LSR) is a liquid silicone material characterized by excellent fluidity, rapid vulcanization, and environmental safety. It has become a high-end elastic material that has garnered significant attention in recent years. Compared to traditional thermoset or thermoplastic rubbers, LSR boasts superior biocompatibility, a wide temperature range, highly automated processing capabilities, and excellent physical and chemical properties. It is widely used in medical devices, baby products, automobiles, electrical appliances, and other fields. This article analyzes the nature, advantages and disadvantages, selection methods, and market trends of LSR to help brands, engineers, and purchasing agents make more informed selection and purchasing decisions.

What exactly is liquid silicone rubber?

Liquid silicone rubber is a two-component, platinum-catalyzed, low-viscosity liquid silicone rubber. It is injected into a mold and cured by heating via liquid injection molding (LSR Injection Molding, or LIM), resulting in a finished product with excellent elasticity and precise morphology.

Main Components:

- Siloxane backbone (–Si–O–Si–);

- Platinum catalyst (for crosslinking);

- Masterbatch and stabilizer

Why is LSR increasingly being used?

Advantages:

Extremely high temperature resistance, maintaining elasticity in temperatures ranging from -50°C to 250°C, making it suitable for high-temperature sterilization of baby pacifiers (230°C) and battery seals for new energy vehicles (-40°C to 150°C).

Liquid silicone rubber is FDA-certified as food grade and does not contain harmful substances such as bisphenol A. It is widely used in food manufacturing and in products that come into direct contact with the human body, such as baby bottles, pacifiers, and medical catheters. It is highly biocompatible, non-toxic, and odorless.

Who is most interested in LSR?

3C and electronic housing manufacturers, including technology companies like Apple and Samsung, are particularly interested in liquid silicone rubber, primarily for waterproof seals in mobile phones. Liquid silicone rubber (LSR) boasts excellent fluidity, rapid vulcanization, and is environmentally friendly and safe. It is particularly suitable for moisture-proofing, insulation, and waterproof sealing in electronic products, such as buttons, gaskets, and seals, which require precise electrical resistance.

Medical device manufacturers:

They require high-precision, biocompatible components, such as catheters and respiratory devices.

Baby and child food container brands:

They require safe materials for pacifiers, teethers, and kitchen utensils.

Automotive parts developers:

They require seals, pipes, and sealing rings for high-temperature and high-pressure applications.

Industrial/household product manufacturers: They require heat-resistant materials for showerheads, kitchen accessories, and sealing valves.

When should LSR be prioritized?

Precision molding requirements:

High product precision is crucial: Liquid silicone has excellent fluidity, making it suitable for filling molds with complex structures. Injection molding allows for the production of high-precision products, such as waterproof seals for electronic products, syringes, sensor membranes, and medical plugs.

Extreme high/low temperature applications:

Liquid silicone maintains its elasticity within a temperature range of -50°C to 250°C, making it suitable for applications requiring extreme temperature resistance, such as kitchenware (e.g., baking molds), outdoor equipment (e.g., waterproof rings), automotive engine compartments, and refrigerator seals.

Conversion period from low-volume to high-volume production: LIM offers high production efficiency and is suitable for production expansion.

High safety/compliance requirements:

FDA and ISO certifications are required. With FDA food-grade certification, it is commonly used in maternal and infant products (e.g., bottles and pacifiers) (e.g., respirator seals), medical devices (e.g., catheters and seals), and items that come into direct contact with the human body, such as food-grade lunch boxes.

High durability requirements: UV resistance, ozone resistance, and aging resistance. Outdoor products (such as sports protective gear linings) have a service life of more than three times that of ordinary materials.

Where is liquid silicone material preferred?

Medical:

FDA-certified, non-toxic, hypoallergenic, and reproducibly autoclavable, it is commonly used for the soft-touch coatings of surgical instruments and wearable medical devices, as well as for sealing and protecting infant and toddler products (such as pacifiers and soothing toys). Liquid silicone is a preferred material for catheters, masks, syringe plungers, and breathing tubes.

Automotive:

Used in engine seals, waterproof structures for new energy vehicle battery packs, and suspension system buffers, it offers both high-temperature resistance (200°C) and wear resistance. It is also used in seals, wiper seals, water pump gaskets, and wiring harness encapsulation.

Electrical and Electronics:

Liquid silicone has a wide temperature range (-5°C to -5°C). Liquid silicone rubber (Liquid Silicone Rubber) is suitable for applications such as waterproof seals in electronic devices, battery pack seals, and shock absorption protection for high-frequency vibration components, as well as for heat-resistant insulating gaskets and silicone switches.

Industrial:

Liquid silicone rubber exhibits minimal permanent deformation and can return to its original shape after long-term compression. It is suitable for high-precision valve seals, flexible protective layers for robot joints, wear-resistant and corrosion-resistant coatings for industrial pipelines, valve diaphragms, liquid level sensor membranes, and seals.

Home and Kitchen:

Liquid silicone rubber is recommended for applications requiring high temperatures and high-temperature sterilization, such as seals for baby products and kitchen accessories.

How to Use LSR?

Liquid silicone rubber is used through an injection molding process, with the main steps including mixing, injection, and curing.

Raw Material Preparation

Select a material with appropriate hardness and certification. Liquid silicone rubber is typically a two-component (A/B component), mixed in a 1:1 ratio. A crosslinker, catalyst, and other auxiliary materials may be added.

Selecting the appropriate liquid silicone rubber requires a comprehensive consideration of material properties, processing technology, and application scenarios based on project requirements. Key considerations include:

1. Material Properties

- Base Color: Liquid silicone rubber typically comes in white, transparent, or translucent base colors. Colors can be adjusted by adding colorants. It is recommended to use a standard color chart to ensure color accuracy.

- Physical Properties: Select hardness (Shore A value), tensile strength (typically 4-12 MPa), and rebound rate (≥70% for high-frequency applications) based on your needs. For example, medical-grade silicone rubber requires ISO 10993 certification, while industrial-grade silicone rubber recommends a tensile strength of ≥8 MPa.

- Chemical compatibility: Substrate adhesion, hydrolysis resistance (vinyl content ≥ 0.15%), and UV resistance (with titanium dioxide addition) must be evaluated.

2. Processing

Flowability and Adhesion: The secondary molding process requires good material flowability and strong adhesion to ensure bubble-free mold filling.

3. Processability: The ease of injection molding and vulcanization processes must be considered. Complex structural parts require a formula with high flowability.

4. Application Scenarios

- Temperature Range: For high-temperature environments, high-temperature resistant silicone (-40°C to 200°C) should be selected. For general industrial products, the temperature range can be relaxed to -20°C to 150°C.

- Media Contact: For direct contact with food or the human body, food-grade or medical-grade silicone should be selected, complying with FDA/LFGB standards.

- Mold design: Mold design must consider thin walls, cold runners, and thermal balance.

- Mixing and Injection: Utilizing the LIM injection molding process, components A and B are mixed uniformly and then heat-cured.

5. Mixing: Components A and B are precisely mixed using specialized equipment to ensure uniformity. • Injection: The mixed liquid silicone is injected into a preheated mold (170-200°C). The injection molding machine controls the pressure and flow rate to prevent air bubbles.

6. Curing

High temperatures (typically 170-200°C) are used in the mold to initiate a cross-linking reaction, forming an elastic solid. This process requires precise temperature and time control.

Post-Processing

After demolding, secondary curing and cleaning may be required. Finally, hardness and dimensional testing are performed to ensure quality.

This process is suitable for the production of high-precision parts in the medical, electronics, automotive, and other fields.

What are the costs of using LSR?

The costs of liquid silicone molding primarily consist of raw materials, production processes, mold development, labor, and transportation and warehousing. The details are as follows:

How to Choose the Right LSR?

Selecting the right LSR material depends on the specific application scenario, primarily considering key factors such as temperature resistance, mechanical properties, chemical stability, and production process. Performance indicators such as Shore A, tensile strength, and compression set should be considered. Our professional engineers will provide expert material selection recommendations based on your project requirements.

Heat Resistance

- High-temperature applications: For automotive electronic components requiring long-term resistance to temperatures exceeding 150°C, high-temperature-resistant liquid silicone rubber is recommended.

- General electronic components: Short-term temperature resistance of no more than 170°C is generally required; materials with good fluidity can be used.

Mechanical Properties

- High-strength requirements: For example, for sensor encapsulation requiring a tensile strength ≥10 MPa, select liquid silicone rubber with a tensile strength of 10 MPa and a tear strength of 30 kN/m.

- Thin-wall structures: Require liquid silicone rubber with high fluidity.

Chemical Stability

Oil/Chemical Resistance: For applications involving chemical media such as SAE 5W-30 motor oil or ethylene glycol, select liquid silicone rubber with a volume expansion rate ≤3% or a flame retardancy rating of UL94 V-0.

Safety

Food-grade or medical-grade: FDA-certified LSR (e.g., for pacifiers) must be clearly labeled as complying with U.S. FDA 21 CFR 177.2600.

Production Compatibility

- Injection Molding: Self-adhesive LSR is preferred, as it can bond to PC substrates without special pretreatment. A fluidity rating of 5-20 g/10 min is recommended to ensure accurate filling.

- Curing Time: Conventional LSR curing times typically range from tens of seconds to several minutes. For thin-walled structures, this time is recommended to be shortened to 30 seconds/mm.

Pay attention to whether the liquid silicone material you choose has FDA/ISO/USP certifications.

Also, confirm with your partner factory whether the mold material, the factory’s level of production automation, and its production capacity match the required delivery volume.

How to control the quality of LSR products?

LSR (liquid silicone rubber) product quality control requires meticulous management across multiple dimensions, including materials, processes, and the environment. The following are key control points:

Material Control

- Supplier Management: Select ISO19001-certified suppliers and require physical property test reports for each batch of liquid silicone (viscosity, hardness, vulcanization speed, etc., with a fluctuation range of ≤±3%). Establish a material database and implement a first-in, first-out (FIFO) principle.

- Material Inspection: Conduct pilot batch tests before production to verify fluidity (viscosity fluctuation ≤5%) and adhesion to the substrate (peel strength ≥2N/cm with batch-to-batch variation ≤10%).

Mold Design and Processing

- Parting Surface Design: Use multi-stage venting grooves (depth 0.02-0.03mm, width 3-5mm), with a clearance ≤0.015mm. Complex structures require optimized gate location through Moldflow analysis.

- Mold Maintenance: Diamond-Like Carbon (DLC) or PTFE coating is applied to the mold cavity surface to reduce demolding force fluctuations by ≤10%. Conformal cooling water channel design ensures a temperature difference of ≤2°C between cavities.

- Process Parameter Optimization: Process parameter monitoring includes temperature, pressure, and injection time.

- Temperature Control: Injection temperature is 130-170°C, PC preheating is 90-110°C, and the holding time is 8-15 seconds to ensure sufficient curing of the silicone.

- Automated Calibration: A high-precision metering pump (accuracy ±0.5%) is used to mix components A/B, and the mixing system is calibrated every 4 hours.

- Batch Testing: Liquid silicone rubber products are randomly inspected for physical properties, dimensional accuracy, and surface defects, and batches are evaluated according to AQL standards of 1.5-2.5.

Media Compatibility Testing

- Material Compatibility: For use in polar solvents or strong acid and alkaline environments, hydrogenated silicone rubber or fluorinated modified LSR is used to prevent hydrolysis/cross-linking reactions between conventional LSR and the media. • Full-process verification: FTIR analysis of molecular bond changes, dimensional expansion (≤5%), and mechanical property retention (≥80%) ensures long-term stability.

- Ensures solvent residues meet standards.

Production environment management

- Temperature and humidity control: The production environment is maintained at 25°C ± 5°C and 50% ± 10% humidity to prevent material performance degradation.

- Clean environment control: Dust prevention and air bubble prevention.

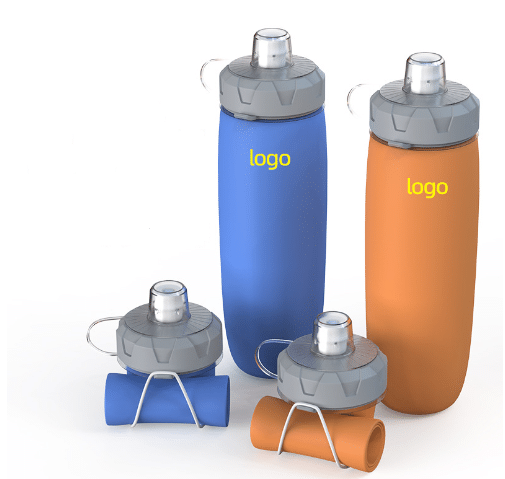

Custom Silicone Products | OEM/ODM Service

How do I clean and maintain LSR products?

Rinse the surface under running warm water. Use a mild detergent or soapy water. Gently wipe away any stains with a soft cloth or sponge, focusing on crevices. After cleaning, rinse thoroughly to remove any foam, dab dry, and air dry (avoid direct sunlight).

For grease stains:

Apply toothpaste or baking soda paste (baking soda and water to form a paste).

Let it sit for 10 minutes, then gently scrub with a soft brush. Apply a spot of alcohol to the surface (avoid penetrating the interior), or soak the surface in alcohol for 3-5 minutes (limit the time to prevent blistering).

For pigmentation (such as coffee or tea stains): Soak the surface in white vinegar or diluted lemon juice (1:1-1:2 ratio) for 10 minutes to loosen the stain, then rinse thoroughly.

For sticky stains (glue marks):

Apply a cotton swab with medicated oil to the stain, scrub gently, and rinse.

Deep disinfection, cleaning, and maintenance:

For high-temperature resistant items (such as cookware and pacifiers):

Boil in boiling water for 5-10 minutes (make sure the product can withstand temperatures ≥ 100°C).

Steam sterilizer/microwave oven for high-temperature steam treatment. Dilute a chlorine-containing disinfectant (such as 84 disinfectant) with cold water, soak for 15-30 minutes, and then rinse thoroughly until no residue remains.

In the medical field, strict sterilization methods (such as autoclave, ETO, and gamma radiation) should be followed.

Prompt cleaning, gentle handling, and thorough drying to avoid chemical corrosion and physical damage can significantly extend the lifespan and ensure hygienic safety.

More FAQs

Summary

Liquid silicone rubber (LSR) is an engineering material that combines high performance with high added value. It is particularly suitable for industrial applications requiring stringent precision, biosafety, and resistance to extreme environments. Although the initial investment is high, long-term use can amortize costs and improve quality through high productivity and low defect rates.

If you require customized LSR selection and implementation support for your specific application, please feel free to contact Z.S.R.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.