How to Put Logos or Patterns on Silicone Bags?

With people pay attention to the environment. Luckily, there are more and more reusable alternatives out there to stop use the of plastic or Disposable. We think the first step to reducing your own waste is to find ways to use the jars and bags you already have. Others, Try to use Silicone bags — silicone bags can be custom different sizes perfect for airtight storing and conserving solid and liquid foods in the fridge, freezer, or on shelves. 100% leaking proof.

What are silicone bags and what is the use of silicone bags?

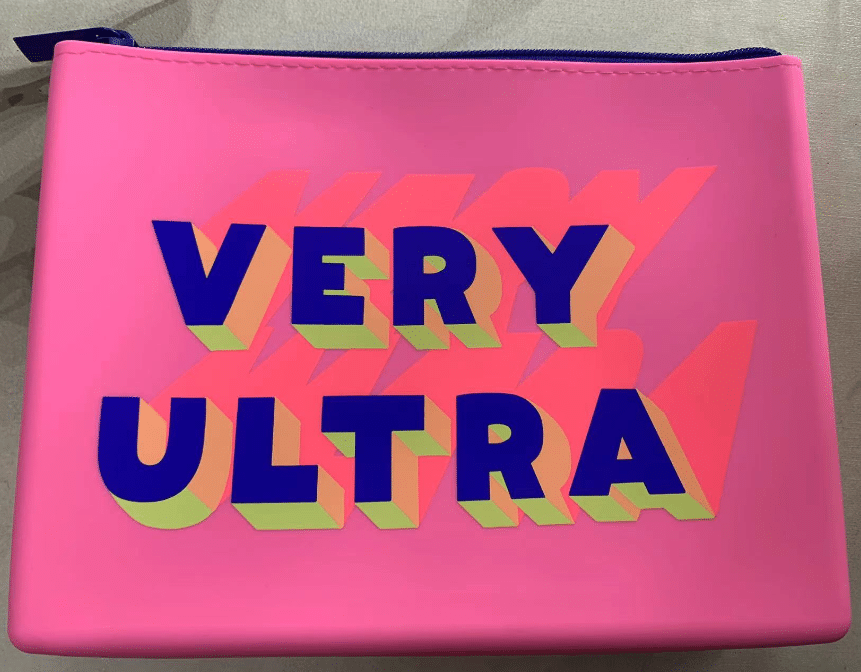

In our daily life. We use different silicone bags: Such as Reusable Silicone Storage Bag, Food Storage Container, Reusable Snack Bags, Silicone pencil bags, Silicone backpack bag, Silicone purse bag, Silicone Belt Bag, Silicone make-up bags, Silicone travel bags etc.

The silicone bags are made of non-toxic & non-allergenic certified food-grade silicone which contains no BPA, no PVC, no latex. Store your food safely. silicone bags for food storage can be reused for years. Sturdy silicone won’t break with heavy daily use. Less plastic waste easily.

The silicone pencil case is not only washable but high temperature resistant as well, making large pencil case ideal for a wide range of applications. The cute pencil pouch can be used as a preppy pencil case, travel purse, makeup bag, tool bag, office supply bag, cosmetic bag and more. Some silicone pouch bag not only can be used for storage but also suitable for your cosmetic, hairpins, keys, coins, stickers, headsets, etc. It can help you collect all the little things and make your life less messed up.

What Are The Benefits Of Printing A Logo or pattern On your silicone bags?

There are many benefits to printing a logo on silicone bags, including:

Increased brand recognition: A printed logo on silicone bags will help your customers identify your brand more easily, increasing brand recognition and recall.

Boosts marketing efforts: A printed logo on silicone bags can help boost your marketing efforts by making your brand more visible and memorable.

Adds a professional touch: A printed logo on silicone bags helps add a professional touch to your product, making it more likely to be taken seriously by potential customers.

Cost-effective: Printing a logo on silicone bags is a cost-effective way to promote your brand, as it is relatively inexpensive compared to other forms of advertising and branding.

Quick and easy: Printing a logo on silicone bags is quick and easy to do, meaning you can get started promoting your brand right away!

How To Print the Logo or pattern On Silicone bags?

1. CNC milling logo on the silicone mold/tooling

Debossed or embossed logo are engraved directly on tool molds during CNC mold-making process. They will not so obvious as other logo processing way. The embossed logo is clear than debossed one. The advantage for this kind logo process is no extra cost for it, the cons are Logo cannot be changed once tool mold is finished. And they most use for food touch products. Like Food shorage bag.

a: Embossed logo Silicone make up bags

This kind of logo is embossed. You can feel it and can touch them.

b: Debossed logo Silicone cosmetic bags

Think of debossing as the opposite of embossing. Debossing is when an image (logo, text, etc.) is imprinted into your print piece, creating a depressed effect. Just like embossing, you can choose to leave the debossed area untouched or fill it in with ink or foil stamping.

Unlike embossing, debossing doesn’t interfere with the back of your print piece, giving you both sides to work with. It can be used on its own, or in conjunction with embossing.

2. Epoxy dripping logo Silicone Purse bags

The Epoxy dripping logo and pattern allow you to put your multi-color logo or pattern put one the silicone bag without printed. They can make embossed logo and debossed logo also. See the picture to get the difference

a: Embossed dripping logo Silicone bags

b: Debossed logo Silicone backpack bags

3. Laser Engraving Logo Silicone storage bags

Engraving, marking, etching: call it what you want, but this technology is great for imprinting images onto a surface. It’s a permanent mark that simply can’t wear off.

You also can choice put your silicone bag logo by laser engraving.

4. Screen Printing LOGO Silicone Purse bags

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

The benifits of screen printing logo and pattern is :Wear-resistant/Can Change color and pattern by Mesh screen. And they Only can printed on the Flat Surface/ Can not make the multi-color, mixed color, fading, Camouflage, Carbon Fiber, Wood Grain colors.

5. Pad Printing LOGO Silicone purse bags

Pad printing (also called tomography) is a printing process that can transfer a 2-D image onto a 3-D object (e.g. ceramic pottery). This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise difficult to print on products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys.

The benifits of pad printing is Wear-resistant/Can Change color and pattern by Steel plate. And they Can not make multi-color, mixed color, fading, Camouflage, Carbon Fiber, Wood Grain colors.

6. Heat Transfer Printing LOGO Silicone cosmetic bags

Heat transfer printing is a method of printing that allows you to print a design onto a piece of clothing or an object. Heat transfer printing uses the process of heat to transfer an image created in wax to an object or garment. This printing method is compatible with pre-painted images on a wax sheet or can be used to create an image by layering wax dye onto an object.

The benifits of Heat transfer printing : Can get multi-color, mixed color, fading, Camouflage, Carbon Fiber, Wood Grain colors/Can Change color and pattern by FilmHeat transfer printing is widely used as it creates durable, heat resistant, adhesive and water-resistant designs. Additionally, the colours created in the image are high resolution with bright and bold colours.

7. Water Transfer Printing LOGO or Pattern Silicone Pencil bag:

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, water marbling, cubic printing, Hydrographics, or HydroGraphics, is a method of applying printed designs to three-dimensional surfaces.

There are wide ranges of water transfer printing films and the most popular patterns include camo, wood grain, carbon fiber, marble, and camo. The camo film is the most popular pattern and is also the common pattern for hydro-dipping guns.

The benefits of Water transfer printing:

- Aesthetics: Any image can be transferred to the product, breaking through the past printing technology, and realizing your printing needs.

- Innovative: Water transfer printing technology can overcome the problems of complex shapes and dead corners that cannot be produced by general traditional printing and thermal transfer, pad printing, screen printing, and surface coating.

- Extensiveness: It is suitable for surface printing of hardware, plastics, leather, glass, ceramics, wood, and other products (cloth and paper are not applicable). It is not limited by the shape of the product. It can also be applied to products that are particularly complex or large, super long, and super-wide.

- Personalization: Do whatever you want, and design any patterns according to customer needs.

- High efficiency: No need for plate making, direct drawing, fast transfer (the whole process only takes 30 minutes, suitable for proofing).

- Superiority: Fast proofing, curved surface printing, personalized printing, small quantity, and much non-paper and cloth printed matter.

- Environmental protection: Residues and wastewater will not pollute the environment

8. In-Mould Decoration LOGO or Pattern Silicone

The in-mold decoration is a modern technique for decorating silicone molded products with unique designs or colors.

In-mold decorating is used to mold high-precision silicone products with exceptional color and appearance. The process involves placing an appliqué – a pre-made form made from a printed sheet of plastic, which then is formed and cut to size – into an mold and molding behind and around the appliqué. It provides all the benefits of silicone molding with the added advantages of modern digital printing.

In-Mold Decorating offers design flexibility and productivity advantages over traditional post-molding decorating techniques. Durable graphics are integrated into plastic components using multiple colors. Since the part graphics are encapsulated in resin, the graphics cannot be removed without destroying the part. Graphics will not fade and remain vibrant. No secondary operation is required after molding. The part is complete. Graphics are updated by modifying the printed overlay. The mold does not need to be modified.

IMD Compared to Pad Printing

- More economical for multiple colors

- Second surface graphics

- Greater ink opacity

- Increased design options

IMD Compared to Pressure Sensitive Labels

- Eliminates secondary operations

- Ability to apply labels on the plastic parts

- Creates an integrated look

- More durable and tamper-proof

IMD Compared to Direct Printing

- Eliminates secondary operations

- More durable and tamper-proof

- Graphics can extend around a radius

- Enhanced 3D effects and surface finishes

Related Blog

Conclusion

Printing a logo or pattern on silicone bags is a great way to give your brand a professional look and feel. With the right tools and techniques, you can easily print your logo onto silicone bags with high-quality results. We hope that our guide has helped you understand how to print a logo or pattern on silicone bags so that you can create stunning products for your business. If you have any questions, please feel free to reach out to us and we’ll be happy to help. So If you need :

- Custom Silicone Bags with Company Logos for Your Business

- Elevate Your Business with Custom Company Logo Silicone Bags as Promotional Gifts

- Connect with ZSR Today to Enhance Your Brand’s Visibility with Custom Silicone Bags.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.